CE standards generally treat types of protection as neat, separate issues… protection against chemicals; or protection against heat and flame; or protection against arc flash and so on.

This is convenient… but unrealistic.

Applications often feature more than one hazard; protection might be needed against chemical and heat and arc flash. Most users have to deal not with single but with multiple hazards.

The obvious solution is to “marry” protection types by combining PPE. Will the properties of one affect those of the other? This can and does happen, and users should be aware of the possible dangers that might result…

This blog looks at the hazards of combining different types of PPE without ensuring they work in harmony and that one does not compromise the other – looking especially at the issue of combined chemical and flame & heat protection.

There are two variations of this problem:-

- Two or more types of PPE must be worn protecting different parts of the body. For example a coverall with gloves, boots and a face mask

- Two types of protection must be worn on the same part of the body to provide different types of protection. For example wearing both chemical safety clothing and FR workwear at the same time because both are needed at the same time – a common situation in the petrochemical and other industries

Combining Different Types of PPE in an Ensemble

| In the case of Lakeland, all CE certified chemical safety clothing is manufactured using a specific coverall design featuring a unique combination of features such as a three-piece hood with shaped center section. This provides a much better fit to most respirator masks than a two-piece hood – commonly used to reduce cost by many manufacturers. You can discover more about the importance of suit design and seam construction of chemical suits here. |

Dealing with the first of these is simple. Optimal compatibility between different PPE is primarily the responsibility of manufacturers – to ensure the design of their product will work with other items of PPE it is likely to be sued with.

For users the question is “How well do different PPE items work together?” For example, how well does a coverall hood fit to the rim of a face mask? Or how effective is the join between the sleeves of the suit and the chemical gloves? Often solutions are improvised, such as taping up the joins with adhesive tape. However, such solutions are untested and it is worthwhile seeking better ones – such as hoods with a superior fit and a glove connection system.

The Dangers of Combining Different Types of Safety PPE

Addressing the second variation is more problematic, partly because problems are less obvious, and because a solution may not be readily available. In protective clothing, a very common example is the practice of wearing a standard disposable chemical suit OVER a suit designed to protect against thermal hazards.

Many users must wear clothing to protect against flame and/or heat hazards – a Thermal Protective Garment or “TPG”, such as a Nomex®, FR cotton or similar, and certified to EN 11612. However, many applications also require chemical protection and the too-often used solution is to wear a chemical suit OVER the TPG. This is a common and global scenario in refining and petrochemical environments where the presence of both hazards is almost universal.

This situation – where a standard disposable coverall is worn over an FR coverall – is also often done simply because TPG’s are expensive and laundering is costly and reduces the lifespan of FR workwear.

This solution however is a serious problem that could compromise the thermal protection provided – perhaps critically.

Why is this Combination of Standard Chemical Suit and FR Workwear a Hazard?

Thermal protective garments work by creating a barrier to heat energy between the source of the heat and the wearers’ skin. However, standard chemical suits will ignite and burn, drip molten, burning debris and adhere to surfaces – including the fabric of the TPG suit worn beneath. Furthermore, disposable suits are constructed of thermo-plastic materials which absorb heat energy and release it slowly over time – molten polypropylene and polyethylene will continue to release heat energy long after it ceases to combust.

| “Wearing a standard chemical suit over FR Workwear may destroy the thermal protective properties of the FR clothing |

The result is that heat energy is transferred through to the skin of the wearer long after the heat source is extinguished. It also blocks up the pores in the TPG fabric weave, creating a “greenhouse effect”, holding the heat energy against the wearers’ skin. In other words the disposable coverall itself becomes an effective heat source whilst destroying the thermal protection offered by the TPG.

The Proof of the Hazard

This is not just theoretical. Thermal Mannequin Testing indicates the effectiveness of TPG’s by using artificial “flash fire” to predict the extent of 1st and 2nd degree body burn.

A video explaining thermal mannequin test is shown below:-

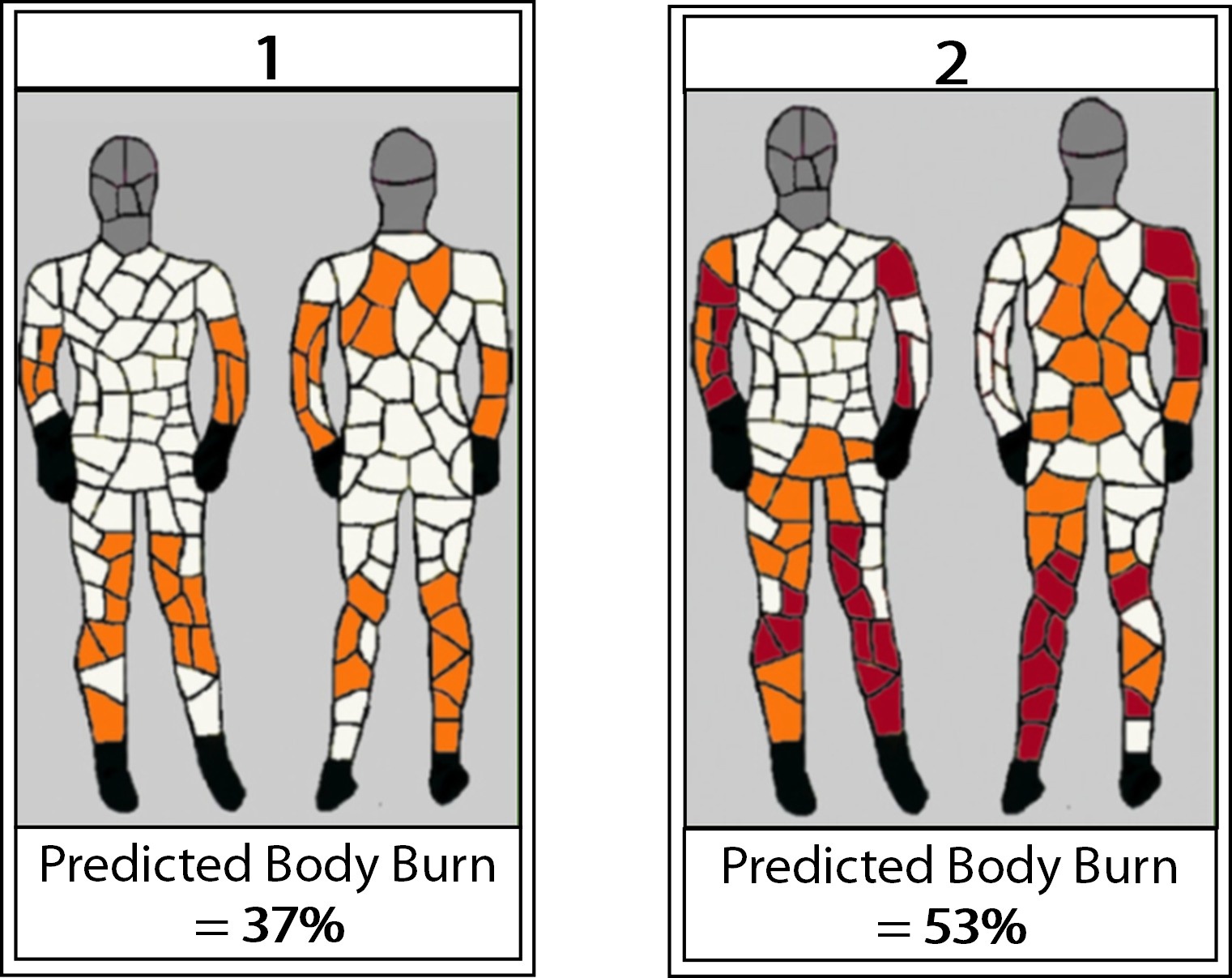

Independent testing using this method of various chemical suits worn over thermal protective garments has been conducted. Body Burn Map 1 shows the predicted body burn with FR workwear only. map 2 shows with a standard disposable chemical coverall worn over it. The results are startling:-

- Predicted body burn for the TPG alone (Body Burn Map 1) was 37% with 1st degree burns only.

- With a standard disposable coverall over it (Body Burn map 2) predicted body burn increased to 53% with extensive 2nd degree burning.

The red areas in map 2 indicate where the 2nd degree burns occurred (2nd degree burns being more critical as they cannot heal and will require skin grafts)… primarily on the arms and legs, precisely where in the test video, the disposable coverall melted polymer can be seen continuing to burn long after the actual burn was extinguished. This increase in body burn – 37% to 53% – and the deeper burns involved could easily be the difference between life and death.

The Solution

Fortunately there is a solution. Properly designed FR disposables – correctly termed as “Secondary FR Workwear and certified to EN 14116 – are available to replace standard disposables.

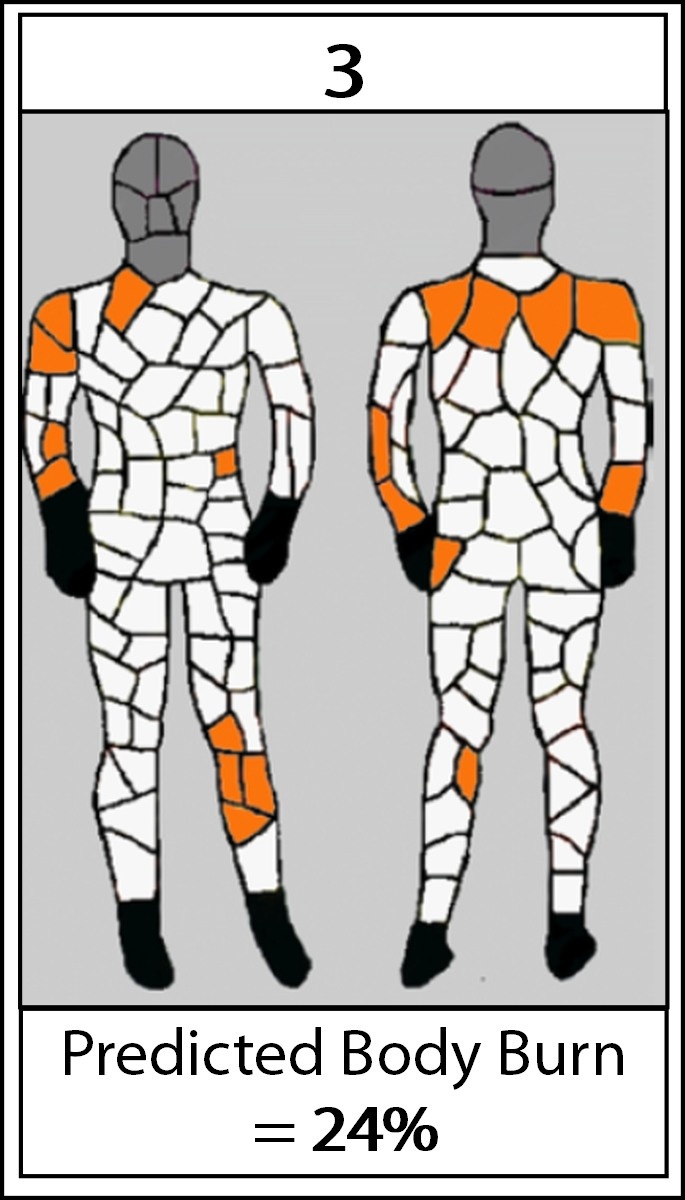

Body burn map 3 is from the same test series, and features a Pyrolon CRFR, a chemical suit using unique fabric specifically engineered for FR properties , worn over the same TPG as used on maps 1 and 2:-

In this case not only are burns 1st degree only, the predicted body burn has reduced to 24%. In other words the thermal protection has substantially improved – even compared to the predicted body burn when the TPG is worn on its own.

CONCLUSION: Take care when Marrying Different Types of PPE

The important point is that when marrying different types of PPE, users should always check not only that they work will together in an ensemble, but even more importantly, whether one has any effect on the performance of the other, and if so, to seek a solution that ensures the marriage is for better and not for worse.

Ensuring one type of PPE will work well with another is just one important step in a series of issue to consider in the selection, management and use of chemical protective safety clothing and other PPE.