Flash Fire

What is a Flash Fire?

A flash fire is a rapidly moving flame spreading through a diffused fuel such as a flammable gas or vapor.

It differs from an explosion in that there is no pressure associated with it. Normally, flash fire quickly exhausts the available fuel and lasts no more than three or four seconds, causing severe burns to the skin and even death.

What is the Purpose of Flame Resistant Clothing?

When a flash fire occurs, the wearer may be engulfed and subjected to a large amount of heat energy in a short time. Flame resistant clothing prevents, delays, or slows the transfer of heat energy from the flames in the flash fire to the skin of the wearer. For this reason, garment integrity is vital, as torn or damaged flame resistant clothing will not protect properly.

Skin burns occur because too much heat energy is transferred to skin from a heat source. To some degree, the skin cells can manage a slow rise in heat energy absorption; however, if too much heat energy is absorbed by the cells too quickly, they cannot cope, break down, and die. It is the rate of heat energy absorption or desorption that is important.

Choosing PPE for Flash Fire Protection

Heat Transfer Methods

Heat energy can be transferred through the following mechanisms:

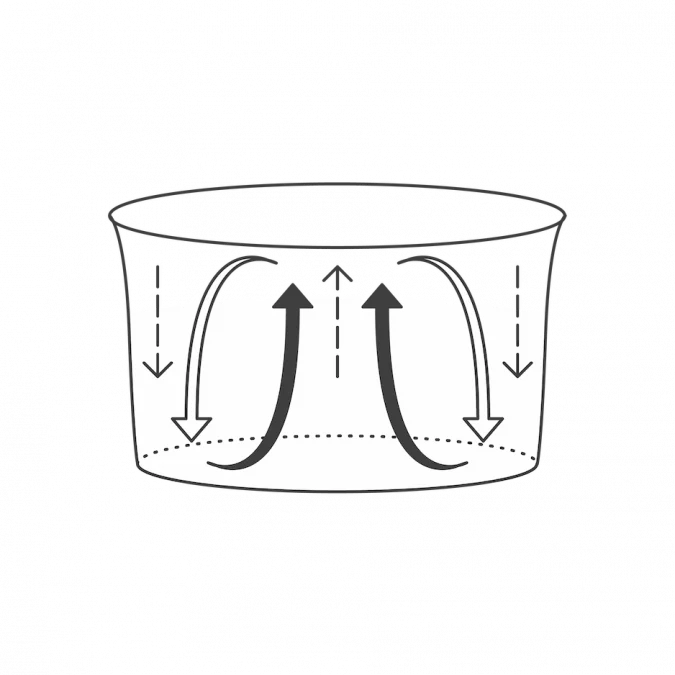

- Convection: Heat energy transferred through medium such as a liquid or the plasma in a flame

- Radiation: Heat energy transferred by infra-red waves (such as the heat we feel from fire or from the sun)

- Contact: Heat energy transferred through direct contact such as when we touch a hot surface.

Heat Transfer Standards

Various standards assess heat transfer resistance of fabric in different ways:

NFPA 2112 includes a single heat energy transfer resistance test with contact and spaced formats measuring contact and radiant heat. A minimum performance resistance is required in the form of a Heat Transfer Performance (HTP).

EN 11612 includes five separate heat transfer resistance tests assessing convective, radiant, and contact transfer, along with molten metal and aluminum drops.

Results of each test are classified as 1 to 3 performance levels (3 being the highest). Both the above standards also contain a heat resistance test and a vertical flammability test.

The heat resistance test shows that fabric does ignite or shrink in a high temperature oven. Shrinking of fabric is important. If shrinkage is too great, the FR clothing would shrink on the body and reduce the insulation from the heat energy.

The vertical flammability test shows that the fabric will self extinguish once a flame source is withdrawn.

Both standards include reference to a “Thermal Mannequin Test” (TMT). In NFPA 2112, the TMT is mandatory and flame resistant clothing must pass with minimum performance. EN 11612, however, does not require the test or any minimum performance levels.

This test subjects whole garments worn on a thermal mannequin (a mannequin covered in heat sensors that absorb energy at the same rate as skin, so simulates a body) to a simulated flash fire. The energy absorbed by the sensors is recorded, using “Stoll Analysis” to produce a “body burn prediction” – a forecast of where on the body a burn is likely to have occurred.

This is the only test that assesses the whole garment, simulates a real-world flash fire, and is perhaps the most important test in terms of indicating comparative performance.

Protect Your People From Flash Fire

Flash Fire FAQ

-

How high can the flame temperature get in a flash fire?

How high can the flame temperature get in a flash fire?

The temperature can get to an excess of 800° C. -

How long does a flash fire last?

How long does a flash fire last?

A flash fire lasts approximately three seconds or less. -

What is flash fire?

What is flash fire?

A flash fire is a rapidly moving flame spreading through a diffused fuel such as a flammable gas or vapor.