When assessing chemical safety clothing requirements, there are a whole range of factors relating to the chemical, the task and the environment to take into account. Yet commonly the focus is on whether the fabric provides sufficient resistance to the chemical in use (with the “breakthrough” offered by the permeation test often being mistakenly used as an indication of safety.

However, the risk analysis on which PPE selection is based should not only highlight the hazards and properties of the chemical, but also any factors relating to the task itself, or in the environment in which the task takes place. Such factors might influence the choice of garment.

Task-related factors influencing PPE choice can vary considerably, and this blog aims to identify the types of factors that might have an influence on the Type and design of chemical suit you choose.

Comfort Is a Safety Issue!

It is important to balance employee comfort with the correct level of protection required for the task in hand. Protection always remains the highest priority, so the instinct might be to over protect just to be sure.

Yet using heavier or bulkier PPE than you need has consequences; not only does it mean spending more on PPE than you need to, heavier and bulkier generally means more discomfort… and comfort is a safety issue.

The fact is, the more uncomfortable is the PPE, the less likely is the wearer to wear or use it properly. Examples of this abound; workers tearing holes in the back of disposable coveralls to allow cooler air in; workers with the zipper pulled halfway down for the same reason, or a mask being removed momentarily for a breath of fresh air… just as a valve bursts and issues a spray of toxic liquid or gas.

Greater discomfort means a lower likelihood of using PPE properly which can become a hazard in itself; it can increase risk. So looking at ways to improve comfort or re-organizing or restructuring tasks to minimize discomfort can not only have a range of positive benefits, it will also help ensure PPE is used properly and protects as it should when it needs to.

How Do Specific Physical Demands of a Task Impact the Choice of Chemical Suit?

Throughout most industries there are countless tasks that require chemical safety clothing, from managing errant sprays of weak cleaning chemicals or mildly hazardous paints, ensuring a process chemical such as a GRP gelcoat does not contaminate the worker, to responding to an accident in a port where a leak of highly toxic gas or liquid may have occurred.

Yet no two tasks are ever the same. The specific factors involved in each may have implications for the choice of fabric and garment. Often this will relate to the physical movements involved in an individual task.

Some tasks might involve merely standing whilst performing a task at a workstation or workbench. This will place minimal stress on the garment and fabric. Other tasks, however, might involve more strenuous or specific movement, placing greater stress on the garment.

Repetitive Movement in a Task

Even simply standing at a workbench could have implications if a specific point on the garment rubs against its edge or another surface repeatedly – with clear consequences if liquids might be spilt on the bench. The effect of a specific, repeated movement might need consideration if it constantly places stress on a particular point on the garment. It might mean acquiring a chemical suit of fabric with higher abrasion resistance or a garment specifically designed with additional reinforcement in the affected area. Alternatively, it might be appropriate to add an additional layer, such as a tough apron, to provide the additional toughness where needed.

Most disposable garments are manufactured using non-woven fabrics which are generally weaker than their woven counterparts – after all, they are principally designed to be used once and then thrown away.

| Testing for Flexibility of Fabric |

The EN test for “flexibility” of fabrics required for all Type certification is the flex cracking test (ISO 7854) which repeatedly flexes fabric until it causes damage, tested by a pressure test afterwards. Particularly heavier disposable type garments often achieve lower classifications in this test… so are not ideal for tasks that require repetitive movement. The EN test for “flexibility” of fabrics required for all Type certification is the flex cracking test (ISO 7854) which repeatedly flexes fabric until it causes damage, tested by a pressure test afterwards. Particularly heavier disposable type garments often achieve lower classifications in this test… so are not ideal for tasks that require repetitive movement. |

So tasks with repetitive movements, even if minor, can stress garment fabric considerably over time – something like a “repetitive strain injury”. In this case, a supple fabric that can withstand repeated flexing over long periods might be more applicable than fabric that is simply strong (stronger non-woven fabrics frequently feature less flexibility). This quality in fabrics is measured with the “Flex Cracking” test (see below). In fabric engineering terms, fabrics that are stronger are often less flexible and show lower results in this test.

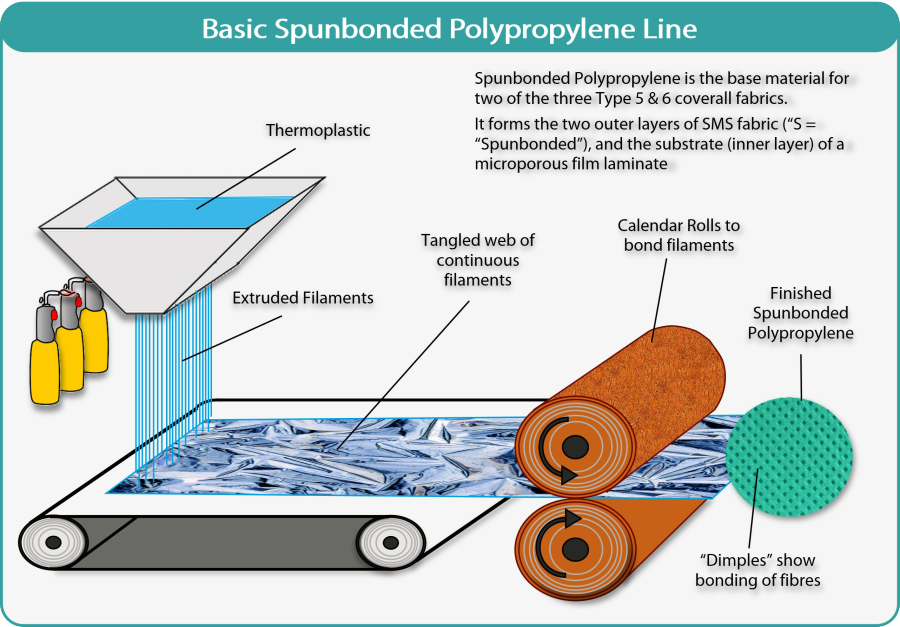

| What are “Non-woven” Fabrics? |

|

|

Tasks Involving Climbing

More strenuous movement can also have specific effects on chemical protective clothing. For example, a task that involves climbing up or down industrial ladders or steps regularly will place additional stress on the crotch and knees of a coverall, possibly resulting in early tearing and destruction of the suit.

It is for this reason the preconditioning movement tests performed before finished garment Type testing [LINK to type test blog] is done include climbing a ladder. Thus, a coverall with additional reinforcement in the crotch and/or knees or a better ergonomic design [super b link], in which the pattern used enables a shorter neck-crotch length (so avoiding the common “low-hanging crotch” found in many garments) might be important.

Tasks Involving Crawling or Crouching

Crawling, especially on a rough floor, obviously places greater stress on the knees of a garment – and potentially on the wrists. So again, fabrics with a high abrasion resistance and/or garments with additional strengthening in the knees or additional knee-pads would be a good choice.

All Lakeland CE certified ChemMax chemical suits feature kneepads consisting of a double layer of the suit fabric with a cushioning fabric between. This not only adds strength, but also comfort and safety. |

Again, the preconditioning movement tests performed before Type Tests includes crawling three meters forward and back to stress the knees.

However, invariably this is done on a clean, smooth laboratory floor that is no doubt swept clean beforehand to remove any specs of dust that might puncture a garment fabric. An example of how lab testing does not always reflect the conditions of the real world where a floor may be anything but smooth and clean.

Working in Confined Spaces

Working in a confined space, such as gaining access underneath machinery for maintenance purposes, could be an important influence on garment choice. It can create multiple stresses and demands on both the wearer and the garment, so choosing a garment with stronger fabric, especially a garment with superior tear resistance, or a garment designed to allow greater freedom of movement, might be critical.

What If a High Level of Mobility is Required?

Any task that involves a great deal of mobility might need special consideration. Even walking will create repeated stress on the crotch area both in terms of tensile stress, repeated flexing and constant abrasion.

In general terms, the most stressed area of a disposable coverall – and the part which usually tears first – is the crotch. Yet in a less well-designed garment, it is also the point where four seams (two leg and two body) meet at one point, making it potentially the weakest point on the garment. In some suits therefor, both the weakest point and the point of most stress are the same.

For this reason any suit that claims an “ergonomic design” should at least feature a strengthened crotch or a crotch gusset, which both gives the garment a three-dimensional shape allowing better fit and freedom of movement. It also means fewer seams meeting at a single point, spreading the stress, and resulting in a garment less prone to splitting at the crotch seams.

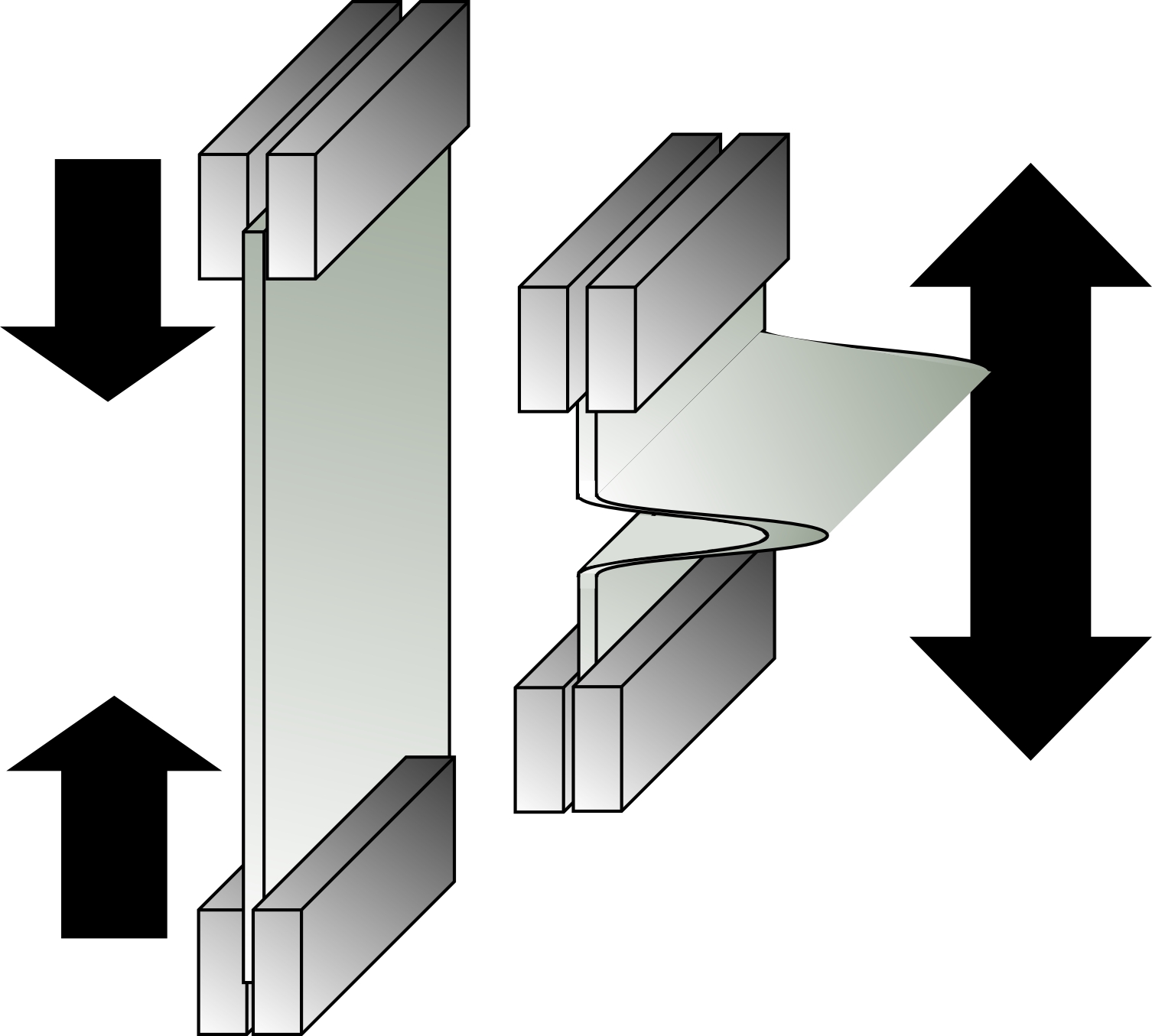

|

|

A Need for Good Visibility and Head Movement?

A driving factor for many buyers of protective clothing is cost – especially where garments are used once and then disposed of. The instinct is that money spent on a disposable item is money wasted. As a result, cheaper garments often have a hood constructed of only two pieces – two sides with seam joining them back to front.

However, two pieces can make only a limited shape for a three-dimensional head! Such suits not only tend to have a curious point sticking up at the top, they also often fail to move with the head, thus restricting visibility, and fail to fit around a breathing mask snuggly.

With this in mind, for any activity that requires frequent head movement, a garment with a three-piece hood means a better fit to the head and mask. A three-piece hoods allows for more head movement without restricting vision or function, especially side-to-side movements and when a breathing mask is required.

All Lakeland CE Type 3 and 4 chemical suits feature a three-piece hood with shaped centre-piece resulting in better fit and freedom of movement without losing visibility |

Size and Fitting

In general terms, cheaper protective clothing (whether disposable non-wovens or re-usable wovens) tends to use simpler designs and, given the biggest cost component in a garment is the fabric, smaller sizing to reduce the yardage of fabric used.

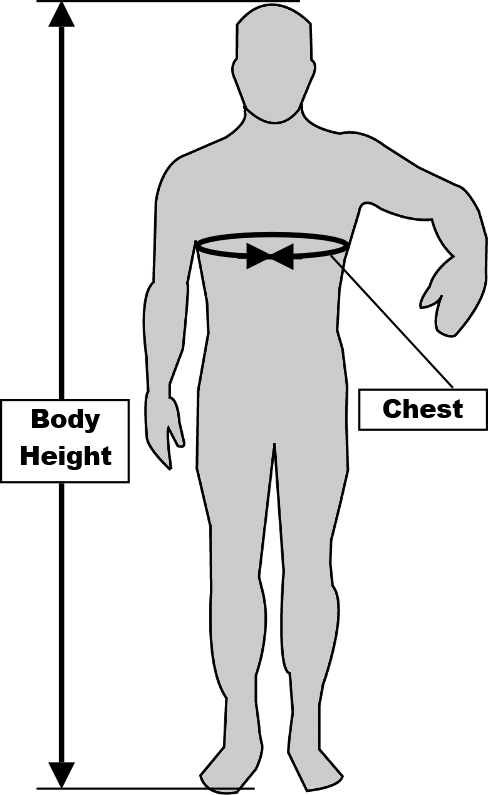

Do Standards Define Protective Clothing Sizing? |

It is a myth that anything in CE standards defines or monitors the size of protective clothing. Whilst the overall protective clothing standard EN 13688 does require the way in which size information is displayed, using the chest and body height of the wearer, it does not define a specification for the actual dimensions of a garment. So one manufacturers size XL can be a different size in comparison to other brands, even though the label might state they are suitable for the same sized person. It is a myth that anything in CE standards defines or monitors the size of protective clothing. Whilst the overall protective clothing standard EN 13688 does require the way in which size information is displayed, using the chest and body height of the wearer, it does not define a specification for the actual dimensions of a garment. So one manufacturers size XL can be a different size in comparison to other brands, even though the label might state they are suitable for the same sized person.

Thus, a cheap garment is likely to be simpler design and smaller size, which means less comfort, less freedom of movement, and a greater tendency to split sooner. And a garment that is half the price does not represent a saving if you use twice as many. |

Heat Stress and Dehydration

A major cause of problems for wearers of chemical safety clothing is that of heat stress and dehydration.

Any working task that requires movement means the body generates more heat and moisture and most chemical protective clothing features very low air permeability so that heat and moisture has nowhere to go.

It is obvious that a fabric that prevents penetration of a liquid spray or fine dust particle will also prevent penetration of air. (The one exception is SMS garments which have a reasonable level of air permeability.)

The more a worker must move around and the more strenuous the activity, the more heat and moisture will be generated and the greater the discomfort and risk of heat stress and dehydration. And this is exacerbated in warmer, more humid environments.

This means better management of the task; perhaps reducing work periods, more frequent rest breaks and ensuring regular rehydration. It also means consideration of garments that, where the required protection allows, will help alleviate the problem, such as two-piece (jacket with hood and pants) or three-piece (jacket, hood and pants) ensembles or a Cool Suit.

|

|

Better and ergonomically designed chemical safety clothing will address many of the issues highlighted here. All Lakeland CE garments use the Super-B style design, featuring a unique combination of elements resulting in better fit, greater freedom of movement and superior longevity. You can read more about the importance of design and the Super-B style here. |

Clearly the demands presented by the activity in a task can present a range of challenges to the Safety Manager in selecting chemical safety clothing.

A robust risk assessment will highlight the key issues and provide a guide to the specific properties and design elements that may be required. But having identified the demands, how can the properties of garments available be assessed in order to judge which is the best option? The detailed testing in protective clothing CE standards provide a useful tool.

How Do CE Standards Help?

The detail in the CE standards is useful for assessing garments to determine if they meet the particular demands of your task. All certified protective clothing is subjected to a series of physical properties tests. These measure various types of mechanical strength, abrasion resistance, tensile strength, tear resistance and so on. Results are reported as standard classifications according to tables provided in the support standard EN 14325, which helps to iron out natural variations in results and enables easy comparison of different products.

Classes for all mechanical strength properties are from 1 to 6, with 6 the highest, and are quoted in manufacturers’ User Instructions, helping you to choose the right garment.

This allows users to build a physical profile of the ideal garment to cope with the specific demands of a task and seek a garment on the market that matches that profile, or to specify a minimum class for a particular strength property that is critical for that task.

For example, as described above, a task involving repetitive movement will require a garment with a better class in the Flex-Cracking resistance test, whilst a task involving climbing may need a garment with high classes in tear and tensile strength. The physical properties tests to which all certified garments are subjected are listed below.

|

Strength Property |

Description |

Classes |

|

Abrasion |

Resistance to rubbing on a rough surface |

1 to 6 |

|

Flex-Cracking |

Resistance to damage as a result of repeated flexing |

1 to 6 |

|

Trapezoidal Tear |

Resistance to tearing of the fabric once already damaged |

1 to 6 |

|

Tensile Strength |

Resistance to basic “pulling” strength |

1 to 6 |

|

Puncture Resistance |

Resistance to the point pressure on the surface |

1 to 6 |

|

Seam Strength |

The same measurement as tensile strength – but across the seams |

1 to 6 |

For more detailed information about chemical safety clothing mechanical properties, test results, where to find them, and how to use them, read our blog here.

The Importance of Garment Design

As mentioned above, garment design can be important. For instance; an application involving climbing will put greater stress on the crotch area, so choosing a garment that incorporates a crotch gusset will be a better choice.

Meanwhile, any stretching or reaching will tend to pull back the cuffs on the sleeves of a poorly designed garment, risking exposure of the wearer’s wrists as demonstrated in the video below:

This wrist exposure problem is the real reason why some manufacturers add thumb loops to garments. At Lakeland, we believe thumb loops are a potential hazard; not everyone uses them as they can be uncomfortable, and if not used, they can dangle and easily catch in machinery. For this reason we avoid them, and as shown in the video the Lakeland Super-B style means the problem is removed.

Never underestimate the potential importance of choosing a garment with a more ergonomic design, which allows greater freedom of movement, results in less stress on weaker areas of the garment, will avoid problems like exposure of the wrists when reaching, and overall, will provide a suit that is more comfortable to wear, more durable, and ultimately will provide better protection for longer.

The temptation and pressure to spend less on disposable PPE is strong but is often false economy… a low-cost suit that is poorly designed and has minimal sizing is no saving if it lasts half as long and must be replaced twice as often often.

Conclusion

Particular movements related to the unique nature of a task can result in specific stresses and strains on garments and could result in damage in use that means a worker is exposed.

It is therefore important that a risk assessment considers this challenge and identifies any movements or activity and how they might affect the choice of fabric and garment design.

Both the detail of physical properties strength tests in CE certification, along with consideration of how overall effective ergonomic design and additional design features (such as three-piece hoods and knee-pads), can contribute to ensuring your chosen chemical safety clothing is the best fit for the job.

Considering issues related to the task is just one element in the selection of protective, management and use of chemical protective clothing. Our next blog will consider issues relating to the environment. Sign up to our blog below to receive notification of when this and other blogs are published.