The revised EN 14325 standard follows Lakeland’s lead and effectively incorporates a calculation of Safe-Use Time for chemical suits.

Every few years European EN standards are assessed and rewritten and new versions and updates are published. However, one standard in particular – a standard last published in 2004 – has been updated and changed considerably: EN 14325.

EN 14325 is a somewhat confusing standard. Whilst many may not recognize it, it is critical for all protective clothing. It is neither a product standard nor a test method standard (although it does include some test methods where separate standards do not exist, such as that for measuring abrasion resistance). Rather, it is the fabric performance and classification standard.

EN 14325 includes all the classifications tables for fabric physical properties, penetration and permeation resistance and seam strength. Thus every PRODUCT STANDARD has clauses stating, for example:-

“…the protective clothing fabric shall be tested and classified for seam strength according to Clause 5.5 in EN 14325.”

Clause 5.5 in EN 14325 then states a test method standard and a classification table showing the classification to be used according to the test result achieved.

For example, in the new EN 14325, the classification table for Seam Strength is given in Clause 5.5:

|

Class |

Seam Strength | Class |

Seam Strength |

| Class 6 | > 500 N | Class 3 | > 75 N |

| Class 5 | > 300 N | Class 2 | > 50 N |

| Class 4 | > 125 N | Class 1 | > 30 N |

So a garment fabric that achieved a result of 105N in the seam strength test would be classified for seam strength as Class 3 (greater than 75N but less than 125N). The aim is to allow users easy access to comparison of garment characteristic performance.

EN 14325 contains similar classification tables for all the physical performance characteristics required in the various standards, including:

- Abrasion Resistance

- Flex Cracking Resistance

- Trapezoidal Tear Resistance

- Bursting Resistance

- Tensile Strength

- Puncture Resistance

- Resistance to permeation by Chemicals

- Resistance to Penetration and Repellency

- Seam Strength

So just how has EN14325 changed?

The latest update to the standard includes a major revision of the classifications for permeation resistance of chemical suit fabrics against chemicals.

At Lakeland, we are pleased to see that the revisions confirm and fully support key points that we have been explaining to users of chemical suits for several years. In fact, the new classification is almost identical to the advice we have been giving those involved in the selection of chemical suits and to those who use our PermaSURE® app for assessing safe-use times for chemical suits.

However, to understand just how the standard has changed, we need to take a look at previous classification.

The original EN14325:2004 standard

The original 2004 version contained a single, simple classification table for chemical permeation resistance: it detailed the time in minutes until the “normalized breakthrough” in a permeation test:

| Class | Time to Normalized Breakthrough at 1.0µg/min/cm2 | Class | Time to Normalized Breakthrough at 1.0µg/min/cm2 |

| Class 6 | > 480 Minutes | Class 3 | > 60 Minutes |

| Class 5 | > 240 Minutes | Class 2 | > 30 Minutes |

| Class 4 | > 120 Minutes | Class 1 | > 10 Minutes |

So a fabric achieving a Normalized Breakthrough of 150 Minutes against the chemical tested would be classified as Class 4 against that chemical. The problem however is that “normalized breakthrough” is not what most users of chemical suits have assumed it to be.

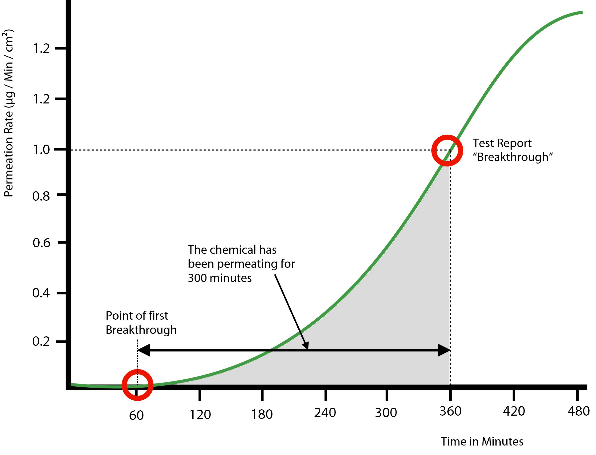

Normalized breakthrough is defined as the time until the RATE of permeation of the chemical through the fabric reaches 1.0µg/min/cm2 – not – as widely assumed – when a chemical first breaks through a fabric. Most users have assumed that a “breakthrough” of 360 Minutes means no chemical has permeated through in that time and so they are safe to use the garment for 360 minutes.

The graph above shows the error in this clearly:

a) The test reported “normalized breakthrough” (where the rate of permeation reaches 1.0µg/min/cm2 ) is at 360 minutes,

b) However, the point of first breakthrough (when the chemical is first identified permeating through the fabric) is at 60 minutes, so,

c) at the point of Normalized breakthrough the chemical has already been permeating through the fabric at an increasing rate for 300 Minutes and may have come into contact with the wearer.

The real danger of this misunderstanding is that users may not even be aware that they have been contaminated – and in the case of highly toxic chemicals, this unrecognized volume of contamination could be critical.

The new EN 14325:2018 standard

The new EN 14325:2018 standard appears to recognize that some chemical suit users misunderstand normalized breakthrough and deals with it by including both the existing normalized breakthrough classification and a second classification of permeation resistance.

This second option is based on the time a chemical takes to reach a specified permeated cumulative mass or volume. In other words, rather than classifying according to the time to reach a rate of permeation, the standard also provides an option to classify according to a calculation of the volume of chemical permeating through the fabric and recording the time until a specific volume has permeated (and therefore may have come into contact with the wearer).

Furthermore, this specific volume is not random; it is related to the assessment of the dermal toxicity of the chemical based on EC regulation 1272:2008 which defines three levels of toxicity for chemicals. The new table of classifications is given below:

| Class | Chemical skin/dermal toxicity based on cumulative permeated mass

(in µg/cm 2 ) Classification based on time to reach cumulative permeated mass |

||

|

Very Toxic |

Toxic |

Other Chemicals |

|

|

Cumulative mass |

Cumulative mass |

Cumulative mass |

|

| Class 6 | > 480 Min | > 480 Min | > 480 Min |

| Class 5 | > 240 Min | > 240 Min | > 240 Min |

| Class 4 | >120 Min | >120 Min | >120 Min |

| Class 3 | > 60 Min | > 60 Min | > 60 Min |

| Class 2 | >30 Min | >30 Min | >30 Min |

| Class 1 | >10 Min | >10 Min | >10 Min |

Thus, a chemical classed as “highly toxic” according to the 1272 Regulation (i.e. one that is sufficiently toxic in that a cumulative mass of 20µg/cm2 might be sufficient to cause harm) that achieves a permeation test result where an permeated mass of 20µg/cm2 was reached in 200 Minutes would be class 4. On the other hand a low toxicity chemical (i.e. “other chemicals”) would only be class 4 if a cumulative mass of 150µg/cm2 was reached in under 240 Minutes (and more than 120 Minutes)

Thus the new standard provides a method of classification that allows users to assess how long a suit can be safely used. This calculation is based on the time until a volume or mass of a chemical sufficient to cause harm (according to the three levels of dermal toxicity – i.e. how toxic the chemical is) has permeated through the fabric.

In short, the new standard is moving towards providing users with two classifications for two different purposes:

- Classification based on normalized breakthrough for comparison of fabric performance (as in the first standard)

- Classification according to a “safe-use time” – the time until the volume permeated may be sufficient to cause harm

The Problem of Temperature

The new EN 14325 standard is a big step forward in assessing chemical suit protection and highlights an issue with permeation testing that we at Lakeland have been explaining to users for several years. However, it is still some way from being perfect – especially since it ignores another major influencing factor: temperature.

Temperature affects permeation rate. As temperature rises a chemical will permeate at an increasing rate (as a general rule of thumb the rate may double for every 10oC rise in temperature). The permeation test standard requires all testing to be conducted at 23oC, so for users working in the real world with higher temperatures, the classifications in the new standard may simply be wrong.

Despite this however, it is a major step forward and at least should help to dispel the assumption that normalized breakthrough is an indication of safe-use time.

The PermaSURE® solution

For us at Lakeland, the most pleasing thing about this new standard is that it supports what we have been saying for years, and it provides users with the information they need to make a more appropriate assessment of chemical suit safe-use times – something our smartphone app PermaSURE® provides as standard.

PermaSURE® uses molecular modelling techniques (based on original work with the UK Ministry of Defense to enable assessment of suits for protection against chemical warfare agents) to calculate permeation rates and, just like the new standard, calculate volume of chemical permeated over time.

And just like the new standard, PermaSURE® compares this to the dermal toxicity thresholds of 20, 75 and 150 µg/cm2 derived from the EC Regulation 1272:2008 in order to indicate safe-use times.

However, what PermaSURE® does that the standard does not, is calculate the permeation rate according to temperature of the environment which is being worked in.

The classification provided by the standard will help towards assessing safe-use time, provided the chemical in question has been tested and the information available. PermaSURE®, on the other hand, provides in seconds an answer as to whether you are safe or not based on chemical exposure time and temperature. With over 4000 chemicals in its extensive database, we think it’s safe to say that no manufacturer of chemical suits in the world can provide such detail.

At Lakeland we like to think we are a market leader; and PermaSURE® is just one example where we are way ahead of the game. Even the internationally recognized CE standards, with the new 2018 version of EN 14325 promoting a concept we have been pushing for the last few years, are still playing catch up!