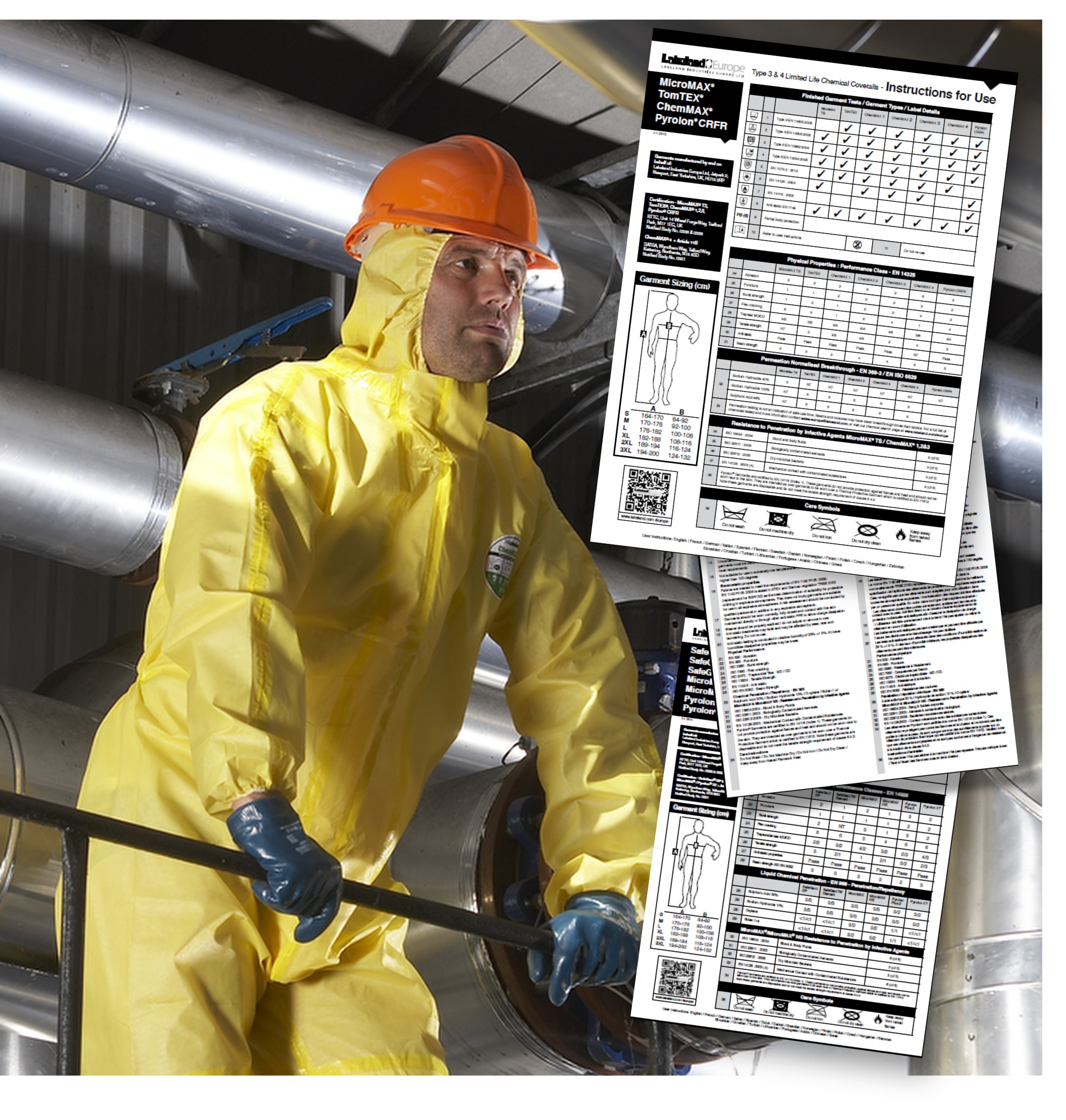

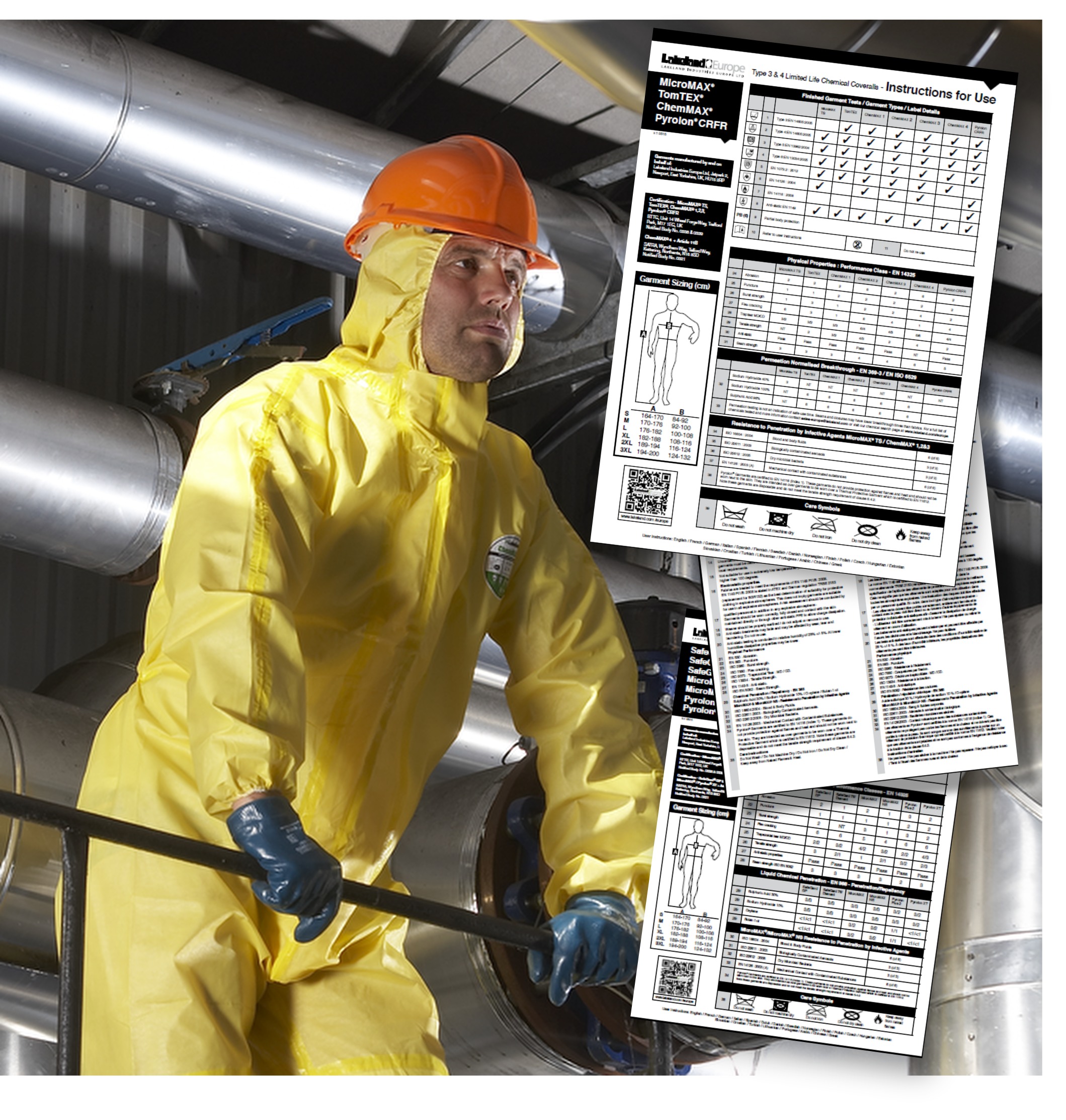

The information included in the U.I. is carefully defined in the product standards and by the certification body as part of the certification process. Each should include an indication of standards applicable, explanations of the various symbols used on the garment label, and very importantly general instructions, guidance and warnings on the product use and importantly, the limitations of use.

As the leading manufacturer of chemical protective clothing, we keep our eyes on the various U.I.’s in the market-place and we’ve noticed a recent trend with some Type 3 garments (i.e. “Liquid-Tight” protection against hazardous chemicals – or garments with sealed seams for protection against strong jets of liquid). It is a trend worth noting if you are a user of such garments – in fact it could be critical for your situation.

The Type 3 garment Type Test comprises directing a powerful jet of liquid at potentially weak areas of the garment – seams, crotch, zip flap etc. In the test it has long been standard procedure to apply additional adhesive tape to the connections between hood and face-mask, wrists and gloves and perhaps ankles and boots in order to maintain a seal in the test and prevent leakage. This is not unreasonable as it is fairly common practice in the “real world” for Type 3 applications. However, we’ve noticed an additional requirement with some newer garments in the market-place. One example is stated as follows:-

“Additional taping of cuffs, ankles, hood and zipper flap required to achieve Type 3 liquid tightness”

It is the addition of “zipper flap” in this taping requirement that raises our eyebrows. The implication is that in order to pass the Type 3 test the zip flap covering the front fastening MUST be taped up in order to prevent penetration of a liquid. This requirement is very different from taping joins between for example, the hood and face-mask which are two different pieces of PPE and rarely designed to fit together with an impervious seal. The front fastening or “zipper flap” is an integral part of the garment itself and a requirement to apply additional tape to it in order to achieve the protection the garment claims is a little incongruous to say the least… the manufacturer might as well claim that the garment provides Type 3 protection and then in small print add a disclaimer stating “but only if a more effective Type 3 garment is worn over it!”.

This requirement for additional taping to the zip flap essentially amounts to an admission that the front fastening design of the garment is insufficient for Type 3 protection and that at best the garment really only provides Type 4 protection.

This is a good example of how it is always worth reviewing user instructions carefully. Not only can there be useful guidance for users, there might also be some surprises which could result in a re-thinking of the protection the product manufacturer claims it provides.