Recently we have noted at least one garment on the European market with bound seams apparently certified to EN 14605, Type 4. There are several reasons why this cannot be correct and we would advise users be wary of such products; a bound seam is not a sealed seam and Type 3 and 4 garments should have sealed seams. This article explains why.

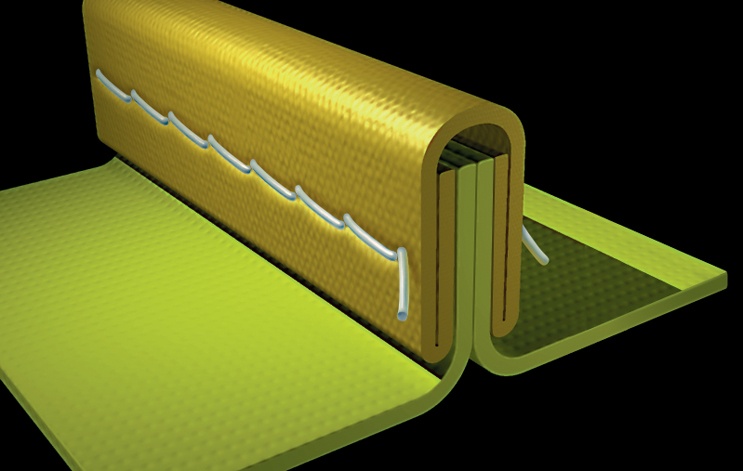

There are generally four types of seams used on disposable chemical protective workwear. “Serged” (i.e. stitched), “bound”, “welded” (either ultrasonically or other) and “stitched and taped”. Of these only the latter two, “welded” and “stitched and taped” seams provide a liquid tight seal. Serged and bound do NOT provide a seal as both feature holes through which the thread passes and through which any contaminant might penetrate or wick.

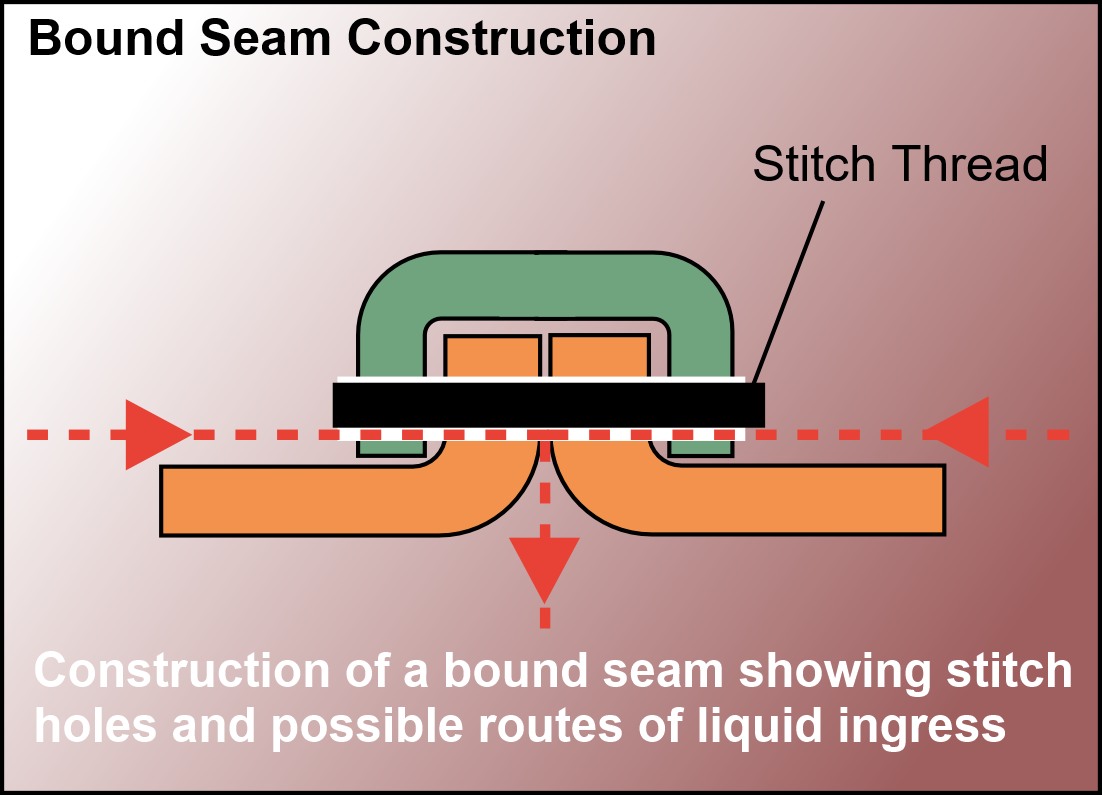

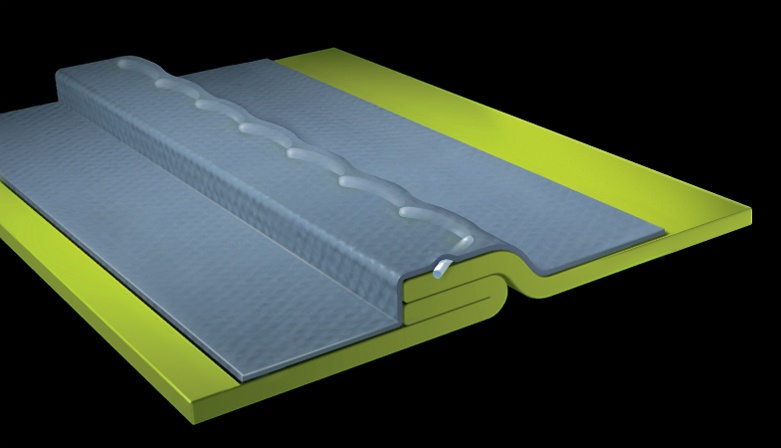

The bound seam in particular causes some confusion. In this the two fabric pieces are brought together in a “butt” configuration and a separate strip of fabric is wrapped around the two fabric edges and stitched into place along the length of the seam. Whilst this is arguably an improvement on a standard serged seam, it is not a sealed seam as it still features stitch holes – essentially open pathways through which a liquid or dust can penetrate – especially if the seam is subject to stress, so that the holes “open” to allow an even more free passage. In addition, the thread itself can be a likely route for a liquid to penetrate, as it often provides an excellent wicking medium.

The bound seam in particular causes some confusion. In this the two fabric pieces are brought together in a “butt” configuration and a separate strip of fabric is wrapped around the two fabric edges and stitched into place along the length of the seam. Whilst this is arguably an improvement on a standard serged seam, it is not a sealed seam as it still features stitch holes – essentially open pathways through which a liquid or dust can penetrate – especially if the seam is subject to stress, so that the holes “open” to allow an even more free passage. In addition, the thread itself can be a likely route for a liquid to penetrate, as it often provides an excellent wicking medium.

This issue is important because while before 2005 there were a number of Type 4 garments on the market constructed with bound seams, since 2005 these have been withdrawn – for reasons that will become apparent below. However, we have recently become aware in Europe of some garments with bound seams, generally imported from Asian manufacturers and apparently certified to Type 4. This is dangerous. There are very good reasons why bound seams SHOULD, and at least one practical, standard-based reason why bound seams ARE excluded from use in Type 3 and 4 garments.

Why Bound Seams SHOULD be excluded for Type 3 and 4 garment construction

Why bound seams ARE (now) excluded for Type 3 and 4 garment construction

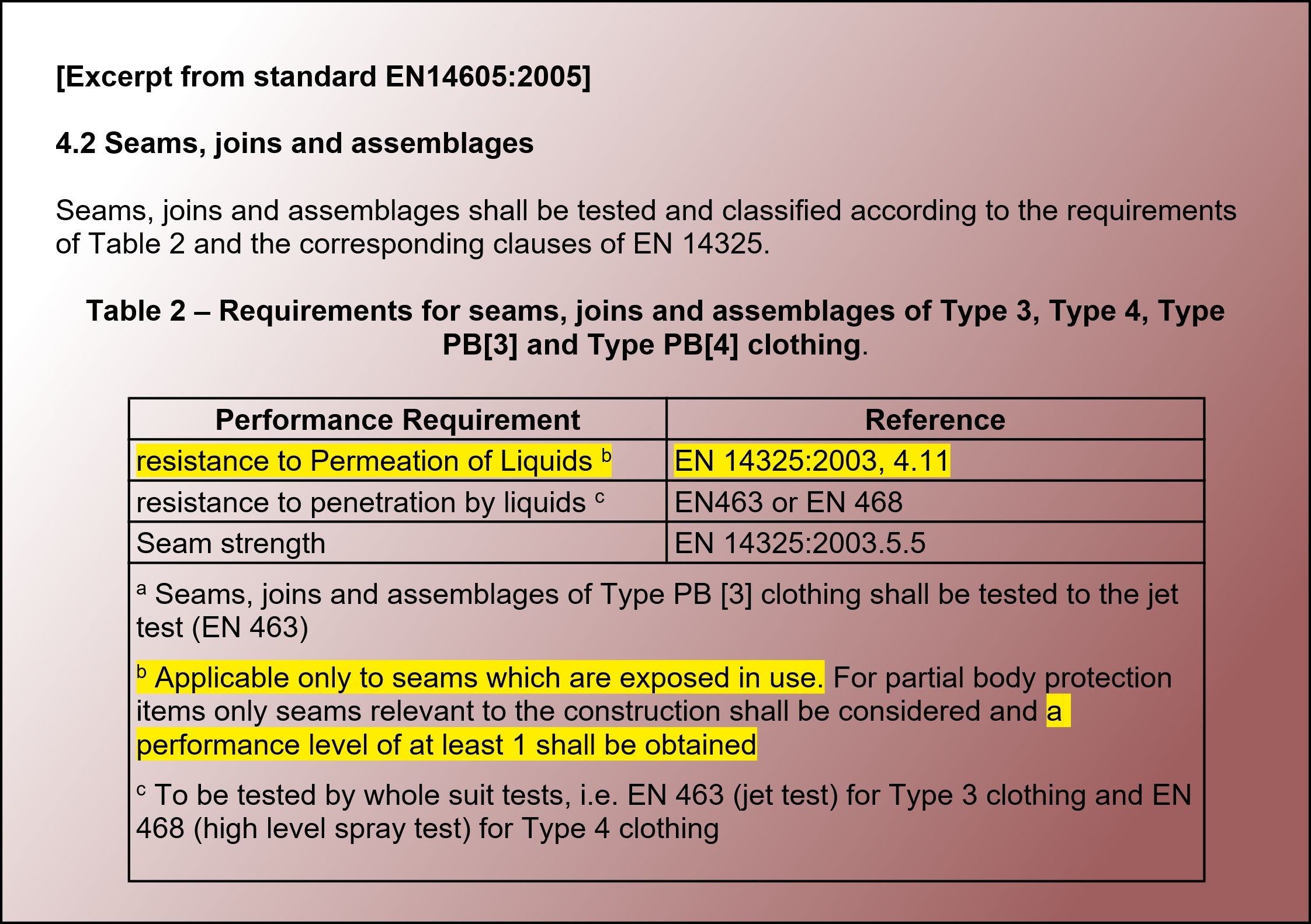

One of the revisions in the 2005 update of the standard was in the requirements for permeation testing of seams against a chemical. The details are in clause 4.2:

[Note: EN 463 and EN 468: in 2005 these were the standards for the finished garment spray tests (Jet and Spray). They have since been superseded by test numbers EN ISO 17491-3:2008 and EN ISO 17491-4:2008+A1:2016 thought the tests have not changed. The EN 14605 standard is currently under review and the references will be updated when any revised version is published.]

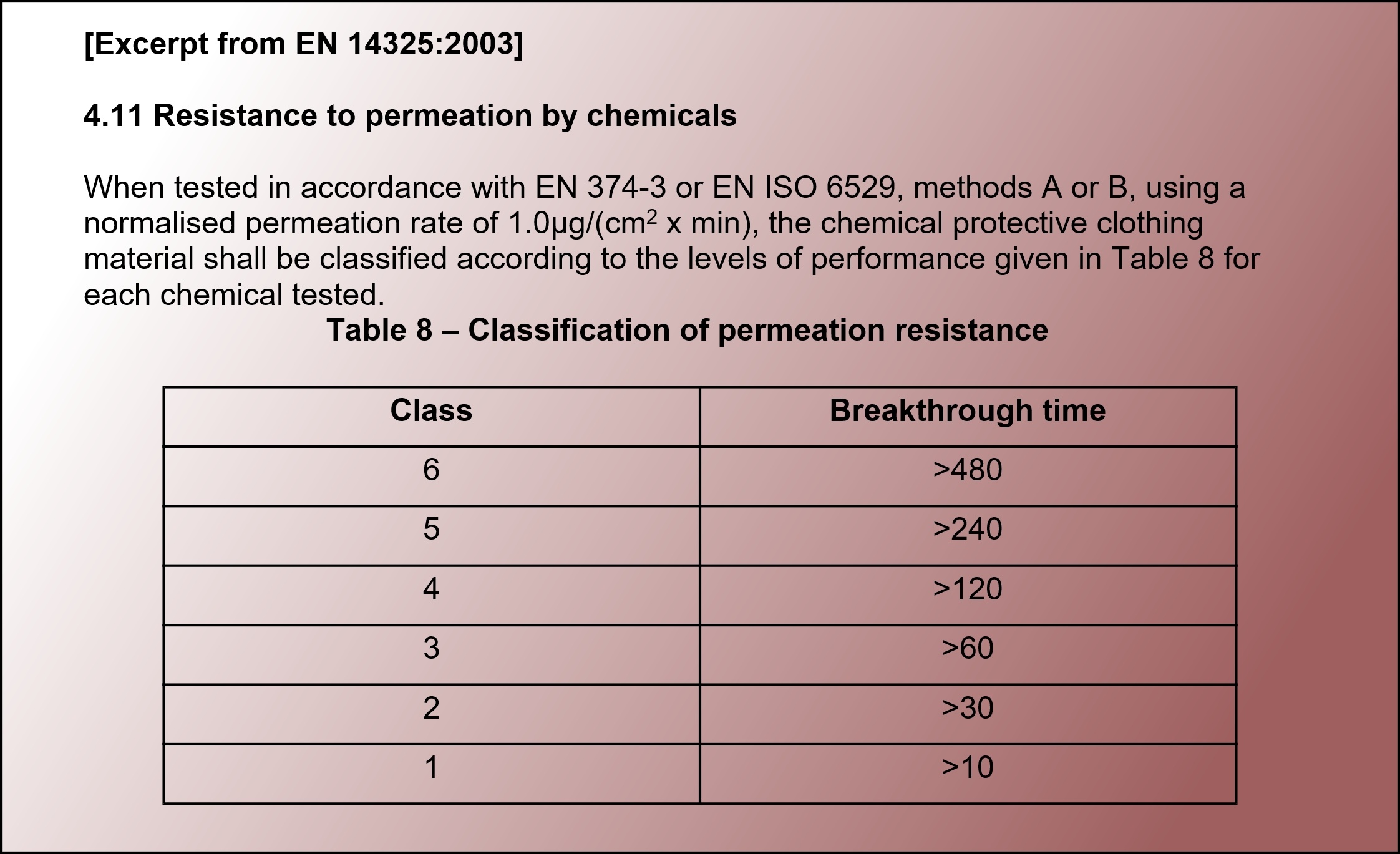

The key parts are highlighted. The clause references EN 14325:2003, clause 4.11. EN 14325 is the standard which defines all the performance classes:-

Let’s summarize what these clauses imply.

1) The Type 3 & 4 standard EN 14605 states that any seams “exposed in use” should be tested for resistance to permeation of liquids according to clause 4.11 in the 14325 standard. What seams are “exposed in use”? Well for practical purposes we can assume all of them… I am not sure anyone would wish to base protection against a hazardous chemical on a guarantee that ANY seam on the garment is NEVER “exposed in use”!

2) The performance class achieved in the permeation test must be at least class 1 – or >10 minutes. (It might be argued that this statement only applies to the requirement for PB (Partial Body) garments – but this would be a manipulation of the standard and contrary to its basic intention – what would be the point of having seams in partial body garments that achieve a minimum standard of class 1, whilst a full garment need only achieve less than a 10 minute performance?

3) Note that neither standard specifies a particular chemical to be tested. Thus the test can be on ANY chemical and whilst most reputable manufacturers undertake permeation tests against a range of chemicals, the standard actually requires that only ONE is tested and that a minimum performance of Class 1 is achieved.

In short, the EN14605 Type 3 and 4 standard requires that both fabric AND seam be tested for permeation resistance against at least 1 chemical and that a minimum performance of Class 1, or greater than 10 minutes, be achieved. And here is the point regarding seam construction. As we described a bound seam is not sealed; it has stitch holes. It is unfeasible that an un-sealed seam could achieve a class 1 in a permeation test against any chemical under any circumstances whatsoever. Quite simply, a bound seam simply could not pass this requirement; ipso-facto, no bound seam garment can be certified as Type 3 or 4.

Conclusion

It was for this reason that in the period following the 2005 revision of the Type 3 and 4 standard existing bound seam Type 4 garments were withdrawn from the market, and it is for this reason that NO Type 4 certified garments with bound seams should now be on the market. Any that are apparently so must be incorrectly certified and should be avoided.

There is a secondary conclusion from this; since 2005 all Type 3 and 4 garments should have at least one chemical permeation test on a seam which achieves at least Class 1. It would be worth confirming that this has been done on the garment you are using.