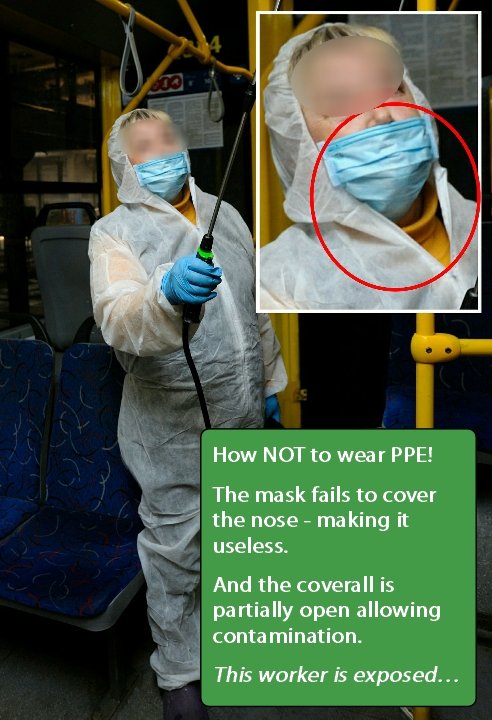

During every pandemic or potential pandemic crisis that makes the global news, we become used to seeing protective clothing pictured or filmed in the news media. For those of us closely involved in the protective clothing industry it can be frustrating. Many such images are examples of how NOT to wear safety clothing if you want it to actually protect as it is designed to. So how do you ensure workers wear safety clothing properly and minimize the risks of protection being compromised?

An example of how not to wear safety clothing is provided by the image below – of a worker in Ukraine disinfecting the contaminated interior of a bus where not only is the face mask not covering the nose, the coverall zip is left partially open leaving several inches of neck exposed. The fact is, if there is a pathogen hazard present, this worker is risking contamination by not wearing the PPE properly.

And this is not unusual or restricted to medical applications or to protective clothing used for viral protection; those of us regularly visiting factories around the world are used to seeing safety clothing worn in a way that means it will not protect as it should.

And this is not unusual or restricted to medical applications or to protective clothing used for viral protection; those of us regularly visiting factories around the world are used to seeing safety clothing worn in a way that means it will not protect as it should.

How can you ensure safety clothing is worn correctly?

Disposable protective clothing is designed, manufactured and worn for a reason: to protect against hazards. And those hazards may have a devastating effect on a wearers’ life – or even end it. So the process of donning protective clothing and making sure it is worn correctly is not a minor issue. Selecting the right safety clothing is only one part of the protective process. Wearing it properly is at least as important.

There is no guarantee of course; but by establishing proper donning procedures and effective and regularly reinforced training the risk can be minimized

With five decades experience working with users to design and manufacture safety clothing for protection against chemicals and pathogenic hazards, Lakeland are well versed in the wearing of suits as well as in the making of them. So to avoid the faults seen in the image here, maximized protection and minimize the risk of contamination, below are twelve tips on the donning and wearing disposable protective clothing.

Twelve tips to ensure safety clothing protects against chemical hazards in the workplace as it should

1. Understand the hazard

Ensure workers understand the hazard they are protecting against. Many chemical and viral hazards are invisible and long term. Unless they understand the consequences of contamination they may under-estimate the danger and not pay attention to detail.

2. Establish a written donning procedure

Not all protective clothing and donning processes are the same; we recommend establishing a written donning (and doffing) process to ensure important and possibly unique issues are addressed. That way workers get to understand those issues and deal with them. Additionally, make sure the process is visibly available in the donning area – perhaps in the form of a poster with reminders about wearing PPE and wearing it correctly.

Watch our donning and doffing advice video below for tips on donning and doffing

3. Train and Review

Ensure training is given to those involved in wearing and donning safety clothing and that the process is regularly reviewed and updated if necessary – especially if the clothing is changed to a different type or brand.

4. Read User Instructions properly

They often contain important information about the suit and include limitations of use that might be critical. For example, some “Type 3” chemical suits are actually only Type 3 in certain circumstances – such as when additional taping of the zip cover is applied

You can discover more about the importance of reading User Instructions properly in our blog here.

5. Work in pairs – ideally the same pair each time

Some parts of donning are best done by a partner – such as final fastening of the zip and storm flap. And only a partner can conduct a final visual check of the the donned garment to ensure there are no damages or tears, that seams are intact and that all fastenings are done up correctly.

And a regular partner will learn the errors you sometimes make and ensure they are addressed.

6. Conduct a visual inspection of the garment before donning

Better to discover any damage or faults before donning rather than discover them once you are wearing it – or worse, when you are in a critical area. Ideally, lay the suit on a smooth flat surface and inspect the front and back, checking that seams and closures are functional.

Seams on some garments may be particularly susceptible to damage and play a vital role in ensuring safety clothing protects as it should. Find out more about seam construction on chemical and biohazard suits in our blog here.

7. Sit Down for Donning

To insert feet into the legs of a coverall sit down and remove shoes or boots. Trying to do this whilst standing and wearing boots is more likely to result in damage to the coverall. You also risk falling over and damaging yourself!

8. Fully fasten zips and closures

The zip on a coverall extends fully to the neck for a reason. If it was intended to fasten 6 inches below the neck it would end there. If you leave it partially open, you leave open an easy route for contamination.

It is always the case that a contaminant will more readily penetrate through holes and gaps in the construction of a garment rather than through a garment fabric – so construction and connection with other PPE is at least as important as the fabric. Find out more in our blog here.

9. If the zip cover is sealable… seal it

The most common route for ingress of particles or droplets in the atmosphere is through the zip teeth and backing materials which is normally woven. For this reason Type 4 and above coveralls normally feature a method of sealing over the zip. So use it.

10. Do you need to seal the coverall joins with other PPE such as masks or gloves?

The most likely route for ingress of contamination if it cannot penetrate through the clothing is to go through the joins between the clothing and other PPE. In higher hazard applications you may need to consider sealing these joins with a good quality barrier tape or using a glove connection system such as push-lock® .

11. Conduct Final Visual Inspection

The final stage before entering any critical area should be a thorough visual inspection by your partner or buddy to identify any damage or faults. Another thing to inspect is to ensure all closures are fastened fully and properly.

12. Do not adjust PPE in a critical area

Clothing should never be removed, partially unfastened – even temporarily for adjustment – in a critical area where contamination could occur. Training in the hazard and clothing and considering the use of more comfortable options, such as Cool Suits, will reduce the likelihood of this.