It’s not as obvious as you might think.

Some manufacturers claim their hazmat suits are disposable. Others say they are reusable. But does that mean a reusable suit can always be worn multiple times? Or that a disposable must always be thrown away after a single use?

No—it’s not that simple.

What Makes a Suit “Disposable” or “Reusable”?

The most notable difference is in the weight and strength of the fabric:

-

Reusable suits are usually made from heavier materials such as butyl rubber, neoprene, or PVC-coated nylon.

-

Disposable suits are generally based on single- or multi-layer polymer films laminated to a nonwoven substrate.

This means:

-

Reusable suits are typically heavier, more cumbersome, and more restrictive.

-

Single-use suits tend to be lighter and more comfortable.

And don’t be fooled into thinking that thicker, heavier fabric means better protection. You might feel more secure in a rugged PVC/nylon suit, but PVC has only limited permeation resistance—similar to an entry-level disposable like ChemMax® 1. By contrast, advanced disposable options such as ChemMax® 3 are still lighter and thinner than PVC, yet provide far superior barriers.

At the higher end of the disposable spectrum, options like ChemMax® 4 Plus and Interceptor® Plus even have fabric strength comparable to some reusable suits.

Fabric thickness plays a role, but true protection comes from the combination of polymers, not thickness. Corrugated cardboard is thick… but would you trust it as a permeation barrier?

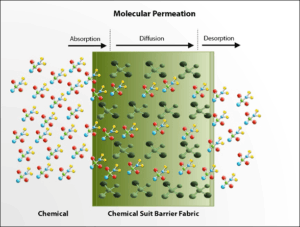

The Role of Permeation

In most applications, the critical factor is permeation resistance, not fabric strength.

Permeation happens at the molecular level:

-

Tiny amounts of a chemical dissolve into and move through fabric.

-

It is measured in micrograms (millionths of a gram).

-

Many toxic chemicals are harmful at extremely small doses.

The danger? A chemical can permeate into fabric without passing completely through. The suit may look fine, but contamination can remain hidden. Washing removes surface residue but not chemicals absorbed into the fabric layers. If the suit is worn again, breakthrough may happen much faster than with a new, uncontaminated suit.

In most applications, the critical factor is permeation resistance, not fabric strength.

Permeation of a chemical through a barrier fabric happens at the molecular level and is invisible to the eye. It involves tiny amounts of the chemical dissolving into and moving through the fabric.

Permeation is measured in micrograms (millionths of a gram). That may sound negligible, but many toxic chemicals are harmful in extremely small doses—with toxicity also measured in micrograms.

And here’s the problem: a chemical can permeate into a fabric over time without passing completely through. You won’t see it. The fabric may look fine, but contamination can remain hidden within the material.

-

Once absorbed, it’s difficult to remove.

-

Standard decontamination by washing is unlikely to make a difference.

-

The surface may look clean, but absorbed chemicals remain.

If the suit is worn again and exposed a second time, permeation can occur much faster than with a new, uncontaminated suit.

Rules for Safe Use

Whether your suit is labeled disposable or reusable, two rules always apply:

-

Never reuse a damaged suit. If it is torn, discolored, showing wear, or if working parts (like zippers) fail, protection is compromised. Don’t reuse it. Repairs also add risk—short of re-testing, you can’t confirm the same barrier performance.

-

Never reuse a contaminated suit. There is no easy way to know if chemicals have seeped into the layers. Even if it looks clean, absorbed contamination may remain.

In short: damaged or contaminated = discard, regardless of the label.

Cost vs. Safety

Yes, chemical suits—especially reusables—are expensive. But the stakes are high. Many toxic chemicals have no immediate effects. They can permeate silently, just as they do through suit fabrics, and symptoms may appear months or years later.

Safe use of a reusable suit may mean using it only once if it has been heavily contaminated. In that case, a disposable might actually be the safer—and less costly—option.

At the same time, a disposable suit may not need to be discarded after a single wear if it is undamaged and uncontaminated, especially in low-risk environments where exposure is rare (e.g., only during unexpected events like a burst valve).

The Bottom Line

-

A “reusable” suit does not always guarantee safe reuse.

-

A “disposable” suit does not always have to be discarded after one use.

-

The decision depends on the chemical, the application, and the level of contamination or damage.

Any business that allows suits to be used more than once must have clear, controlled processes in place. The most critical step is a thorough visual inspection by trained personnel to confirm there are no signs of damage or contamination.

With proper inspection and controls, the choice between single-use or reuse becomes a matter of application—not just manufacturer labeling.

Ready To Make The Right Choice?

Contact the Lakeland team to learn more about safe chemical suit selection and to better understand the real differences between disposable and reusable suits. We can help you match the right protection to your specific chemicals and tasks.