If you work in an environment that requires protection from flash fire and chemical hazards, you’re probably familiar with secondary FR apparel. Our article here explains the difference between secondary and primary fireproof clothing, but for a brief recap:

Primary fire-resistant clothing is designed to protect against flame and heat hazards, such as flash fire, while secondary fire-resistant clothing is to be worn over primary FR clothing to provide other types of protection – such as chemical – without compromising your primary FR protection.

This is important where users need both chemical and flash fire protection at the same time. Or, in situations where users wear a disposable coverall over a primary FR garment simply to keep it clean and manage cost.

So, what’s on the market in terms of secondary FR workwear? How can you determine its effectiveness at protecting your people in hazardous environments? Read on to find out.

SMS/SMMS FR Coveralls

When you start trying to find secondary FR workwear, you’re likely to come across SMS or SMMS FR-treated coveralls.

SMS and SMMS are synthetic fabrics made from polypropylene and are commonly used for disposable coveralls. They combine air permeability with particle filtration so are ideal for Type 5 & 6 or OSHA Level C disposable clothing.

Being based on polypropylene, SMS/SMMS is flammable, so is unsuitable for secondary FR workwear.

However, by adding a chemical FR treatment to the fibre, some limited FR properties can be achieved. There are now several such FR-treated SMS garments available. But how do they perform in thermal mannequin testing and in the real world?

We looked at three major global brands of FR-treated SMS disposable coveralls in terms of FR certification and thermal mannequin test data, referred to here as FR SMS A, B, and C.

Certification to EN 14116?

The essential EN standard for basic FR fabrics used for protective clothing is EN 14116. This comprises a single “vertical flammability test” with a basic requirement of no burning or dripping of molten material.

The latest version (published in 2015) introduced additional requirements including testing on garment components (the seams, zip, etc.) with the same minimum performance.

So, the first test of FR SMS garments is “are they certified to EN 14116?”

We analyzed datasheets, CE certificates, and Declarations of Conformity for the three products. The results are shown in the table below:

| Referenced Document | FR SMS A | FR SMS B | FR SMS C |

| Claims in Data sheet or brochure | States material “complies with” EN 14116 2008.

Note: quotes the old version of the standard. |

Claims “flame retardant” and “flame resistant treatment”. | Claims “certification to EN 14116: 2015” |

| CE Certificate | No mention of EN 14116 or any other FR standards | No mention of EN 14126 or any other FR standards | – |

| Declaration of conformity? | – | – | Certification to EN 14116 – but states “applicable to fabric only” |

| Conclusions | Fabric may meet requirements of the old standard, but the product is NOT certified to any FR standards | Garment is NOT certified to any FR standard. | Appears to be certified to EN 14116: 2015 but ignores the requirements that were introduced in that version. |

In short, two of these FR SMS garments are not certified to EN 14116 or any other FR standard at all. The third is certified to EN 14116:2015 – yet only partially and apparently ignoring the requirements introduced in the 2015 version!

But what about performance in Thermal Mannequin Tests?

Thermal Mannequin Tests on FR SMS garments

Despite extensive research no manufacturer-supplied data could be found.

In its absence, we commissioned independent testing to discover any notable difference in performance between the FR-treated SMS and the non-FR-treated SMS versions of the same product.

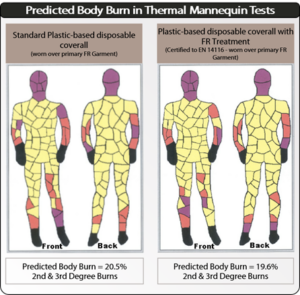

We purchased both options from one manufacturer and conducted testing, with each worn over the same primary FR garment. The results are shown below:

The results are startling:

- The non-FR-treated SMS garment achieved a predicted body burn of 20.5% and included both 2nd and 3rd degree burns.

- The FR-treated version achieved a predicted body burn of 19.6% – again including 2nd and 3rd degree burns. In fact, the FR treated version had slightly more 3rd degree burns!

In other words, there was less than 1% difference in predicted body burn between the FR-treated and non-FR versions of this coverall.

The conclusion? Neither of these garments are fully certified to any FR standards, and there is no manufacturer’s data available on thermal mannequin testing that could confirm their efficacy.

In our independently conducted thermal mannequin tests, we found there was minimal difference in performance between the non-FR-treated and FR-treated SMS garments.

The Third Option: Specialist Secondary FR Workwear – Pyrolon®

Pyrolon® Secondary FR clothing is based on a non-polymer fibre specifically engineered for FR properties. In contact with flame, rather than igniting, it chars, maintaining its integrity for longer and when worn over a primary FR garment, adding a layer of insulation.

Two banks of thermal mannequin tests have been conducted to prove its effectiveness: –

- Comparison with Standard disposable chemical suit

Where the standard disposable coverall worn over the primary FR garment increased body burn from 37 to 53%, the same test conducted with Pyrolon CRFR resulted in a body burn prediction of just 24% – not only much lower (less than half) the body burn shown with the standard disposable coverall, but considerably lower than the primary FR garment worn alone!

In other words, in the test Pyrolon effectively enhanced the total thermal protection of the layered system.

- Comparison with FR SMS garment

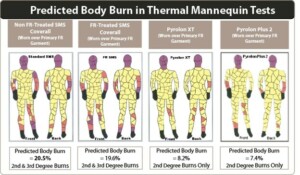

Following the testing of the non-FR and FR SMS garments, Pyrolon Plus 2 and Pyrolon XT were also tested. The predicted Body Burn maps and results are shown below:

Pyrolon XT and Pyrolon Plus 2 resulted in much lower predicted body burn – less than half the SMS options. In addition, both resulted in 2nd degree burns only.

Clearly, Pyrolon garments not only avoid any increase in predicted body burn, they also actively enhance the total thermal protection of the layered system, adding to the thermal protection provided by the primary FR garment, and substantially reducing predicted body burn.

Testing of the three possible options, standard disposable coveralls, FR SMS coveralls or Pyrolon, proves the following:

- Standard, polymer-based disposable coveralls and chemical suits must not be worn over primary FR workwear. To do so puts workers at risk of serious – and possibly fatal – burn injury.

- Based on the three major global brands analysed, FR SMS options appear ineffective. Certification to EN 14116 is either non-existent or partial and thermal mannequin testing indicates almost no difference in performance compared to non-FR SMS coveralls.

- Pyrolon secondary FR workwear garments are fully certified to EN 14116 and, in thermal mannequin tests, are proven to not only avoid the risk of increasing burn injury but to actively enhance total thermal protection.

Pyrolon garments are the only secondary FR workwear options proven to work.