This blog considers Secondary FR Workwear; its importance, the different types and the fact that three specific brands in the market are not certified as users probably assume them to be. The result could be that users of these types of safety clothing may not be as well protected as they believe.

What is Secondary FR Workwear?

In many industries – but especially petrochemical – workers need protection against flames (the risk of flash fire) and against chemicals at the same time. Normal practice is to wear a chemical suit over the primary FR workwear (i.e. workwear certified to EN 11612). There are four important points about this:

- Because standard chemical suits are generally made from thermoplastic polymers that will ignite and burn, they cannot be worn over primary FR Workwear. This is because in the event of contact with flames they will ignite, burn and effectively destroy the thermal protection it offers.

- Specialist Secondary FR Workwear is designed to be worn over Primary FR workwear to provide chemical protection without destroying thermal protection

- There are different types of Secondary FR Workwear:

- Specialist garments based on non-plastic fabrics engineered to not ignite and burn, such as Lakeland’s Pyrolon™

- Plastic based “SMS” garments with a chemical FR treatment. These are referred to as “FRSMS”. They tend to be cheaper… but are they as effective?

- Both of these types appear to be certified to the same standard… but are they the same?

What are the standards?

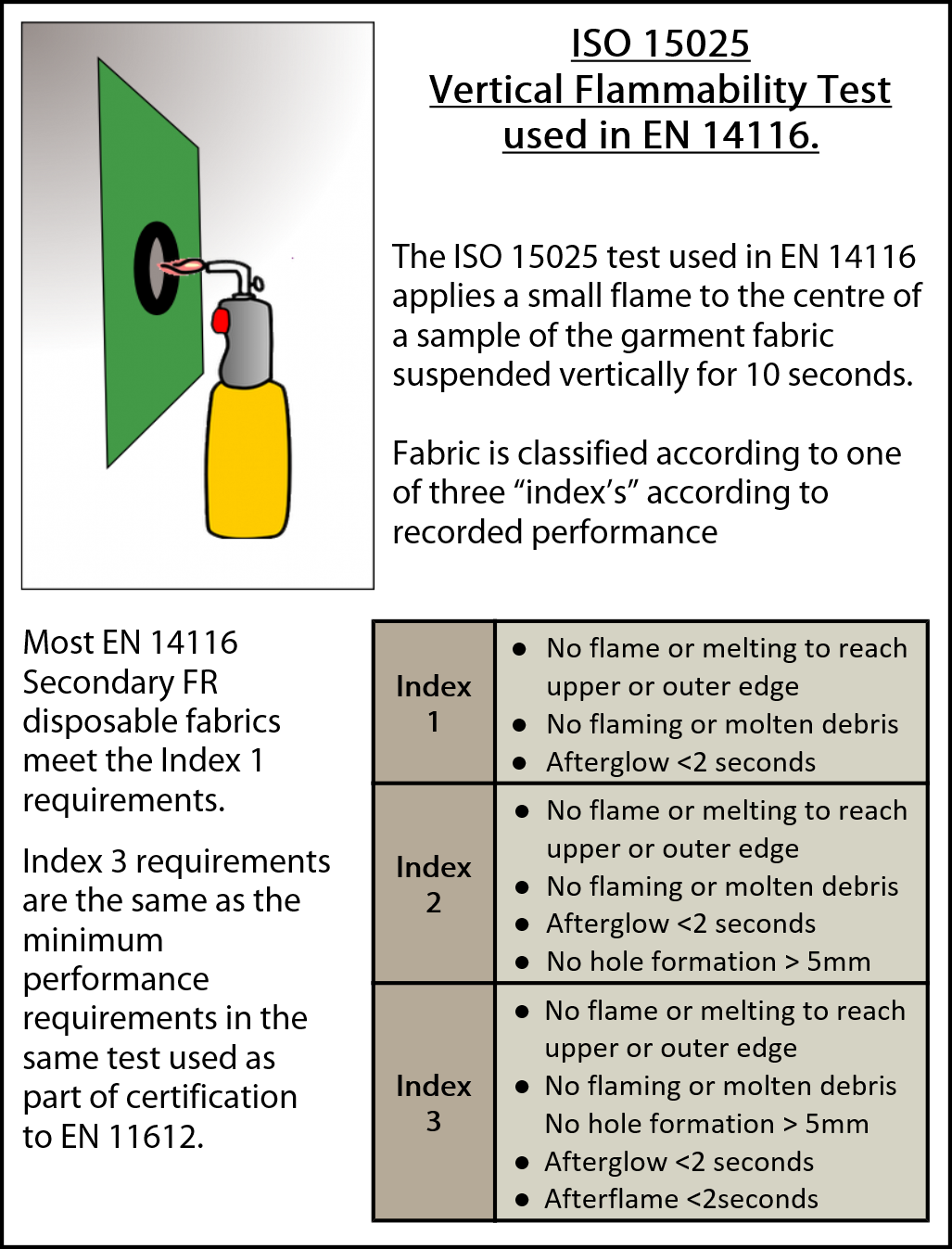

Whereas primary FR workwear is certified to EN ISO 11612 intended to prove suitability to protect against flames and heat, secondary FR workwear is certified to EN ISO 14116 . This is designed to indicate how a garment or the fabric it is constructed from reacts in contact with flame. It consist of a simple vertical flammability test (EN 15025) and defines three performance levels or “Index’s” as shown in the image below.

Secondary FR Workwear of both types listed above general achieve Index 1 in this test. (Note this test is also used in EN 11612 and the Index 3 requirements are a minimum requirement).

Secondary FR Workwear of both types listed above general achieve Index 1 in this test. (Note this test is also used in EN 11612 and the Index 3 requirements are a minimum requirement).

An important change in the standard

Until 2015 the EN 14116 standard required this test on the fabric with a minimum performance level of Index 1. However, in 2015 a new version of the standard was published which added new requirements. The main change was that not only garment fabric should be tested but that other components – notably the front closure system – must also be tested and meet the same minimum performance requirements. In addition it requires that the front closure should continue to function after the test.

|

It was clear when this standard was updated that one type of Secondary FR Workwear – FR SMS garment – would simply be unable to meet this requirement. This type of fabric relies on disintegration before ignition can occur, so the fabric cannot protect the plastic closure from the flame. It will ignite and burn and the test would be failed. The only way to achieve this would be to make a substantial change in the garment that would result in an unfeasible increase in cost. For this reason FR SMS garments should have either undergone a severe re-design in order to pass the new requirements or have been withdrawn as they are unable to meet the requirements of the standard.

Yet not so. In 2020 at the time of publishing of this blog FR SMS garments remain available in the market, unchanged and apparently – and I stress the word “apparently” – certified to the EN 14116 standard. So how as this been done?

Lakeland have looked at three branded FR SMS garments in the market and:-

- Analysed their certification

- Commissioned independent testing to EN 14116:2015 of freely bought samples.

For obvious reasons I will not name the products here but refer to them as Brand A, Brand B and Brand C. All are SMS based fabric with FR treatments and all would appear to be certified to EN 14116. It should also be noted that these are not cheap imported garments but well-known brands from major global suppliers of PPE.

Analysis of the certification of Brands A, B and C

The tables below show the results of each analysis:

Brand A |

|

| Web Site Product page | Several statements indicating secondary flame spread resistance treatment and EN 14116 Index 1 is stated (though no date shown). |

| Technical Data Sheet | States “Fabric is treated to provide limited flame spread resistance (FSR) when worn over an Index 2/3 garment”. |

| Certification Information | Certification section does not include the FR pictogram but states:

“Flame Resistance: Limited protection against flame spread. Materials has been tested to ISO 15025:2000 and complies with ISO 14116:2008 requirements for limited flame spread resistance Index 1** “The “**” refers to note: “must be worn over an Index 2 or 3 garments and must not be worn next to the skin” [sic] |

| CE Certificate | Makes no mention of flame retardant properties or any FR standards including EN/ISO 14116. |

| Declaration of Conformity | Makes no mention of flame retardant properties or any FR standards including EN/ISO 14116. |

|

Brand A: Conclusion |

Whilst the marketing information claims the fabric “complies with” the requirements of EN 14126:2008 (i.e. the old version) neither the CE certificate nor the Declaration of Conformity make any mention of it. Brand A is NOT certified to EN 14116. It does not meet the same specifications as a product that fully meets the requirements of EN 14116 and has not undergone the same testing. |

Brand B |

|

| Web site product page | Several indications of “Flame retardant SMS materials” and “flame Retardant”

Standards overview states… “EN ISO 14116” The standards and certification section states “EN14116:2015”. |

| Technical Data Sheet | States “Flame Retardent”, “SMS fabric with fire retardant… treatment” and “EN 14116” |

| Labelling | Includes “Limited flame spread – EN ISO 14116:2015 Index 1” (with warning triangle). |

| User Instructions | Includes statement: “Meets the requirements of EN ISO 14116: 2015 Index 1 with the exception of clause 6.1.4. The coverall did not pass the seam flammability test. The end user must decide on the basis of a risk assessment whether or not the product is suitable for the intended use”. |

| CE Certificate | No certificate available from web site. |

| Declaration of Conformity | Makes no mention at all of EN 14116. |

| Conclusion: Brand B | The marketing material, labelling and user Instructions claim the fabric meets the requirements of EN 14116:2105, whilst admitting this applies to the fabric only and the product “did not pass the seam flammability test”, though it does not refer to any test on the front closure system.

Whilst a CE certificate appears not to be available from the web site, the Declaration of Conformity makes no mention of EN 14116. Since the Declaration of Conformity is based directly on the CE certificate it is a fair assumption that Brand B is not certified – or at minimum not FULLY certified to EN 14116. |

Brand C |

|

| Web Site product page: | Includes the statements:

o “Flame-retardant polypropylene SMS nonwoven fabric, providing limited protection against flame spread (index 1)” o “EN 14116 Index 1 (limited flame spread)” o “Limited Flame Spread EN ISO 15025:2003 Limited flame spread procedure A” |

| Labelling | Includes “EN 14116:2015 Index 1 (with warning triangle). |

| User Instructions | Includes the statement:

“This coverall is made of a fabric which offers protection against flame according to EN ISO 14116:2015 Index 1. [warning triangle] Only valid for the fabric. Verify suitability for use”. |

| CE Certificate | EN ISO 14116:2015 (protection against flame – Limited flame spread materials, materials assemblies and clothing) for a performance classification of Index 1. |

| Declaration of Conformity | Includes: EN 14116:2015: (Protection against flame – Limited flame spread materials and clothing), for a limited flame spread index 1. Only valid for the fabric. |

| Conclusion: Brand C | As with Brand B the web site repeatedly mentions EN 14116: 2015. However the User Instructions and Declaration of Conformity confirms that this only applies to the fabric and not the components. The CE certificate includes EN 14116 but makes no mention of the exclusion shown in the user Instructions and Declaration of Conformity. This must be an error on the certificate which should include an exclusion stating the certification applies only to the fabric. |

In Summary:

Brand A

Despite claiming in marketing materials “Secondary Limited Flame Spread” including a mention of EN 14116, based on the CE certificate and Declaration of Conformity this product is not certified to EN 14116 at all.

Brand B

Marketing materials suggest the fabric meets the requirements of EN 14116 whilst the datasheet and user instructions warn this only applies to the fabric and states the certification excludes clause 6.1.4 (see below). However, whilst a CE Certificate appeared not to be available from the web site, the Declaration of Conformity makes no mention of EN 14116. Since the Declaration of Conformity is based on the CE certificate it can only be assumed that Brand B is also not certified to EN 14116.

Brand C

Whilst marketing materials suggests the garment meets the requirements of EN 14116:2015 the User Instructions and Declaration of Conformity again confirm that this only applies to the fabric. So once more whilst the CE certificate includes the standard it is at least not certified to the whole standard and has not met the requirements of components to pass the ISO 15025 test.

Summary of independent testing

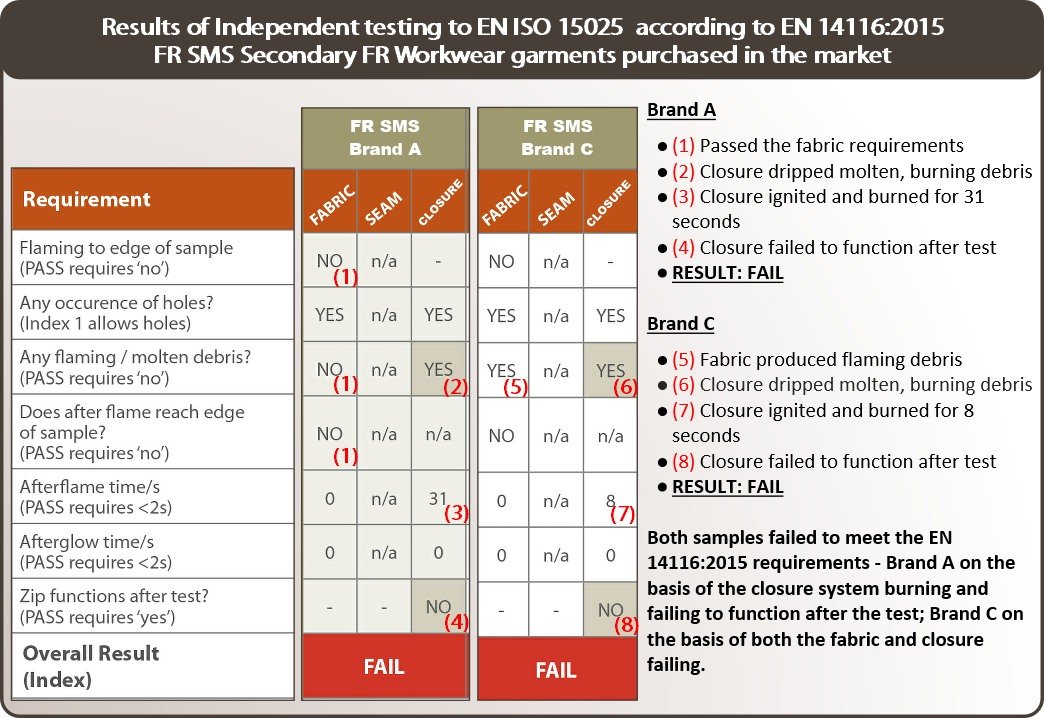

Samples of two of these brands, A and C, were purchased from the market (a sample of B was not available at the time) and sent for independent testing to EN ISO 15025 according to EN ISO 14116:2018.

The results are detailed in the table below:

In summary, whilst based on the marketing information users might assume these products meet the requirements of and are certified to the EN 14116:2015 standard:-

- one appears not to be certified to it at all

- another may be certified to it but excluding the components test requirements;

- the third is certified – but excluding the requirement for the components test.And in the independent testing of two of the brands:

- one failed on the basis of the front closure (which ignited and burned for 31 seconds!)

- the other failed on both fabric AND zip requirements.

It is therefor safe to assume that none of these brands of FR SMS coveralls meet the full requirements of EN 14116:2015

And bear in mind that these coveralls are all well-known global brands supplied by companies considered to be amongst the global leaders in PPE.

Conclusions…Does this matter?

The fact is that none of these three products fully meet the standard EN 14116:2015. The question is of course whether it matters; are these products safe to use? There are three issues to consider in answering this question:

1) These products have been certified on a principle of “certification to EN 14116 except for specific parts of it”. Should this be allowed?

Actually, it may surprise some but this does happen and it is not uncommon. An example is the EN 1079 (standard for dust protection in the nuclear industry) to which most disposable garments are certified to except for a specific clause requiring a minimum puncture resistance performance which disposable fabrics simply cannot achieve.

Whether it SHOULD be allowed is of course debatable. It is difficult to agree a definite rule but a logical approach ought to be whether the exclusion relates to an issue which is fundamental in the products intended ability to protect against the hazard; in the above case the puncture issue is not critical to the performance of the garment in that it does not affect its ability to protect against penetration by dust or liquid but only in its ability to maintain integrity in more strenuous environments.

However, in the case of Secondary FR Workwear the standard was changed in 2015 specifically to introduce a requirement for components to be tested as a safety issue; the product is intended to avoid ignition in the event of exposure to flames. Additionally, standard front closures are made from plastic which will ignite and burn. So excluding the new requirement is in direct contradiction of the principle purpose of the PPE.

If these products are certified at all it is on a principle of “certification to the new standard except for the new requirements introduced in that new standard”. So in practical terms they are actually certified to the old standard and not to the new one at all. Certification to an old standard is NOT allowed, so if this is not actually breaking the rules it is certainly bending them considerably…

2) The problem of clarity and transparency.

It is important to note that these products do make it clear in the user instructions that certification relates to the fabric only and not to components, though that is less clear in the marketing tools.

However, user instructions are detailed, complex and necessarily involve lots of information crushed into a small space – and in multiple languages. As a result they are difficult to read; picking out a specific sentence in a large block of text in very small font is a challenge. So how many people actually read these instructions carefully and notice a particular sentence (though we always advise doing so)?

And even if they do, how many users would actually understand the full implications, that in effect it means they do not fully meet the requirements of the standard and what that means for the performance of the product in the real world?

There is a clear argument that even where such exclusions are made and reasonable they should be made far more explicit and include an indication of the implications – and in marketing information as well as user instructions.

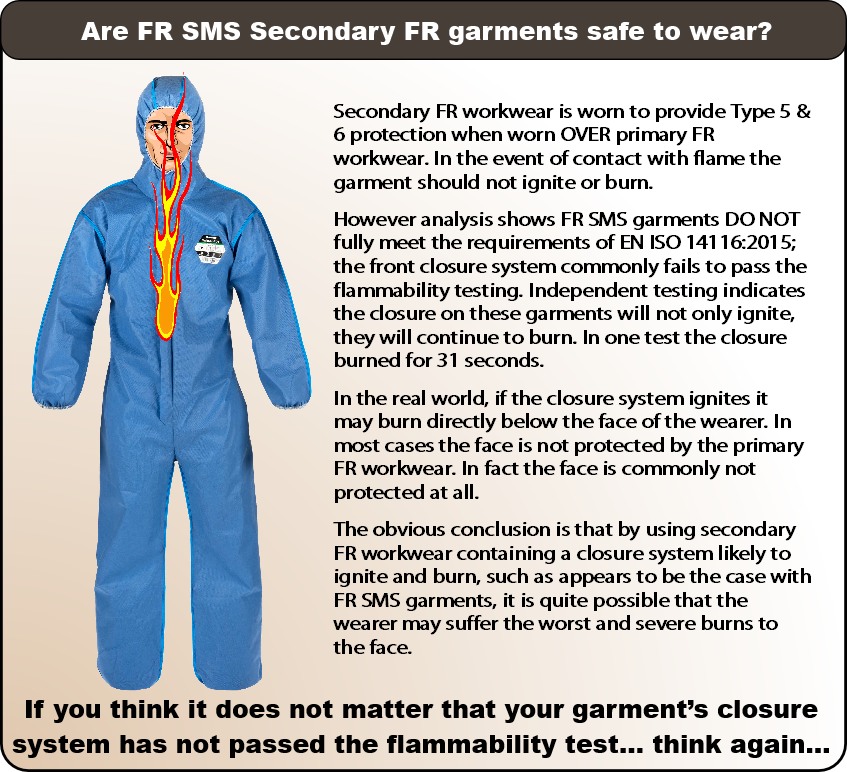

3) Are FR SMS garments safe to use as Secondary FR Workwear?

For Safety Managers this is the real question. If you are using FR SMS coveralls that partially meet the standard excluding the requirement for testing of components and especially the zip… are you safe?

To answer this it is useful to return to the basic intention of the PPE. Secondary FR garments are intended to be used to provide protection against liquids and dusts when worn OVER primary FR Workwear that is certified to EN 11612. They work by avoiding ignition and burning; standard disposables cannot be used because, being plastic they will ignite, drip molten debris and continue to burn, destroying the thermal protection provided by the primary FR Workwear beneath. FR SMS garments resolve this problem on the fabric by introduction of an FR treatment – with varying degrees of success (Note that in the testing above Brand C failed the fabric test as well as the zip test).

However, the EN 14116 standard was updated in 2015 because of recognition that components on garments are plastic and WILL ignite and burn, thereby potentially compromising the effectiveness of the garment. Yet it is clear that especially the front fastening on FR SMS garments comprises plastic which will ignite and burn if not adequately protected (as shown in the two tests where one burned for 8 seconds and the other for an astonishing 31 seconds!). Clearly then, in the event of a flash fire the closure will burn, and especially considering removal of the garment may be impeded, the failure to ensure these components will not burn is a clear hazard that may, in the event of a flash fire, result in greater harm… precisely what this PPE is intended to avoid. So allowing exclusion of testing of components as required in the revised 2015 standard is in direct conflict with the specific intended use of the garment.

But there is another safety issue here that should be considered – and typical of the type of issue that can occur in the real world yet that standards commonly fail to address. If a closure system ignites and continues to burn for 8 or 31 seconds as was the case in the tests above, it could burn immediately below the wearer’s face – which in normal circumstances is not protected by the primary FR garment at all. So even if the flash fire is relatively minor and quickly extinguished, if the closure ignites there is a real possibility of plastic continuing to burn immediately below the neck and face of the wearer. The consequences could be devastating. It is easy to see that the tendency of the front fastening system on these garments to burn is a genuine hazard.

But there is another safety issue here that should be considered – and typical of the type of issue that can occur in the real world yet that standards commonly fail to address. If a closure system ignites and continues to burn for 8 or 31 seconds as was the case in the tests above, it could burn immediately below the wearer’s face – which in normal circumstances is not protected by the primary FR garment at all. So even if the flash fire is relatively minor and quickly extinguished, if the closure ignites there is a real possibility of plastic continuing to burn immediately below the neck and face of the wearer. The consequences could be devastating. It is easy to see that the tendency of the front fastening system on these garments to burn is a genuine hazard.

So are these FR SMS garments safe to use?

No… based on the evidence here… they are not…

To learn more about the tests used to assess the effectiveness of FR workwear, download our new eBook and discover how to select clothing where protection against heat, flame and/or hazardous chemicals is required.

{{cta(‘b25cc460-7ad6-429a-ac19-2dbdcdbeab31’)}}