While we all love to soak up a bit of sun, none of us enjoy working in the heat. Parts of Europe experienced their hottest summer in more than a decade as temperatures hit 44C (111F). High temperatures can make it difficult to maintain concentration and stay hydrated and cool.

For office workers, the solution might be turning on the aircon and loosening a shirt button or two. However, for those working in hazardous environments, where chemicals and dangerous materials are routinely used, it’s not so simple.

PPE (Personal Protective Equipment) ensures the safety of the workforce. But, though mandatory, protective clothing in hot and arid conditions can cause discomfort and can influence an employee’s ability to do their work properly. In the heat, employees may unzip or remove their PPE just to cool down, exposing them to potential hazards and risks.

So, what does this mean for Safety Managers? How can they keep their workforce safe and comfortable in hot weather?

Education on the risks of PPE removal

Education is key. It needs to be reiterated that, regardless of temperature, the removal of PPE in chemical environments is dangerous. Safety Managers need to regularly remind employees of the importance of wearing their PPE correctly.

Some employees might think that, due to the apparent lack of immediate harm from chemicals, unzipping or removing their PPE is perfectly acceptable. However, many chemicals (especially carcinogens) may have no immediate effect. The damage becomes apparent over time – with health problems emerging and exposing businesses to legal action. It’s worth ensuring users of PPE understand that just because a chemical does not apparently cause immediate harm, it does not mean it is not doing harm.

Getting the right PPE equipment

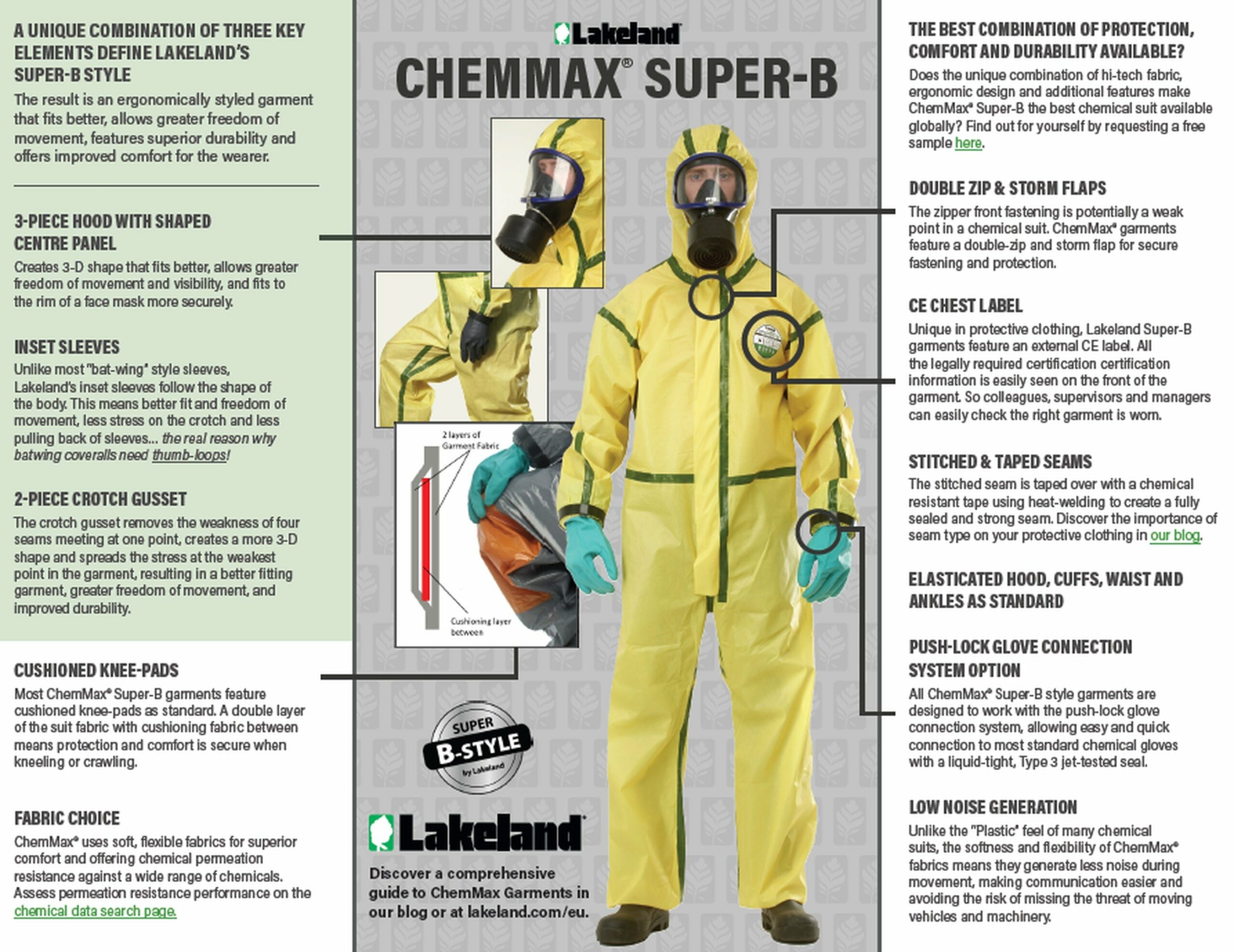

The next step is ensuring the correct balance between comfort and protection by making available more comfortable designs and options that may be available. This might involve targeting protection more accurately and ensuring workers are not being given more protection than they actually need (there might also be a cost benefit!). For example, for chemical splash protection users commonly wear Type 3 coveralls – even when most applications are Type 4 rather than the more demanding Type 3. In this case a more comfortable Type 4 option may be available and suitable.

In chemical protection, it’s also important to remember that permeation speeds increase as temperatures rise; a suit that has an acceptable working time at 20C may have a much lower safe-use time at a higher temperature. Safety Managers need to find PPE that can provide protection against permeation at higher temperature levels, as well as keep employees cool. Design options that offer a greater level of comfort and allow a longer working period, whilst providing adequate protection are certainly something to consider.

Keeping employees hydrated and rested

Lastly, there’s a simple solution to the overheating issue that’s sometimes overlooked – and that is keeping employees hydrated. Plan to allow employees to take more frequent breaks, remove PPE and hydrate. This could mean designating a ‘cooling down’ area with water and snacks available to keep employees cool, comfortable and energized.

The protective process is twofold; employees must have the right equipment that keeps them cool and comfortable and have a thorough understanding of workplace safety and the importance of wearing PPE. By ensuring employees are cool and comfortable in the warmer seasons, work performance can be increased significantly and safety be upheld throughout the operation.