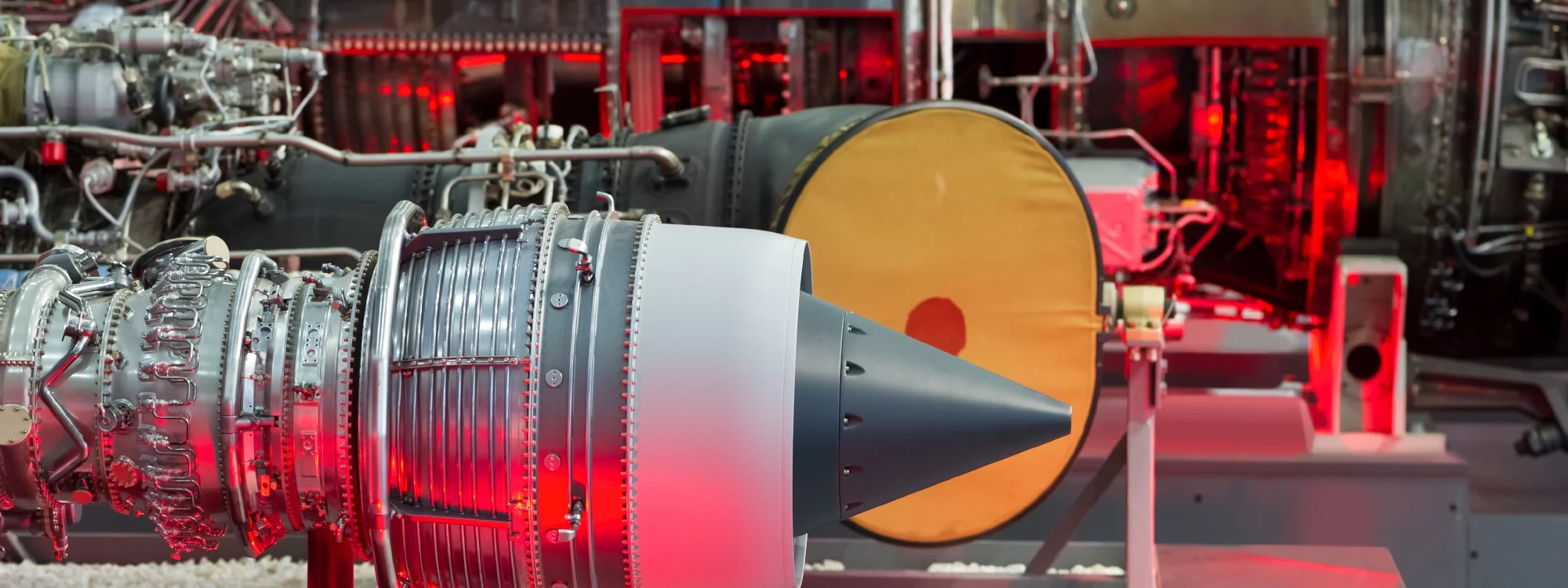

The aerospace industry is comprised of the construction and design of aircraft products and services. A few of these products include aviation missiles, private and public aircraft, and general space systems.

The general sector of aviation includes recreational or private transport. A few examples are company-owned aircraft or business aviation, personal travel, airborne law enforcement, forest fire maintenance, and tourism. Military aviation includes the dedicated air corps that handle military operations. Aerial combat, cargo transportation, intel missions, and training personnel are a few examples. Commercial aviation handles passenger travel and the import and export of products and goods.

Due to many countries’ certification standards, the aerospace industry is strictly regulated to ensure the highest level of safety when handling manufactured equipment and technology developments.

With the complexity of manufactured products within the aerospace industry, many employees are exposed to physical hazards. Possible effects can range from minor scratches to hearing and sight loss – even long-term effects, such as cancer and amputations. Many of these hazards occur on the manufacturing floor site due to these environmental causes:

Whether it be an individual or a piece of material, falling objects and hazardous heights expose countless hazards within airframe manufacturing. Due to the extensive height of most aircraft, each assembly task poses a threat for an employee to fall from the working platform or aircraft surface.

Construction materials and machine operations involve high-strength fabrication, chemical milling, and electronic discharge from welding and drilling. The associated processes when handling these tolerances can expose employees to repeatable dermal and airborne contact with various levels of gases, vapors and mists. The electronic beams from welding within confined areas of the manufactured aircraft create susceptible radiation exposure. Other ergonomic hazards include:

Among these hazards, many employees might encounter oxygen deprivation, musculoskeletal injuries, and entrapment. With assembly and manufacturing processes shifting frequently, the aerospace industry continuously integrates safety management systems throughout national and multinational levels.

Despite engineering safety systems, the aerospace industry requires personal protective clothing to maintain factors that could cause personal harm to employees. PPE found within this industry helps sustain protection for skin, lung, and body exposure. Though varying on the environment, individuals commonly wear:

Technicians and operators dealing with chemical exposure respiratory protective equipment and chemical coveralls are mandated. Fire-resistant coveralls and equipment protect welders and operational handlers from sustaining major burn exposure.

Aviation maintenance poses inherent on-site risks, requiring essential safety practices. Due to the large equipment, heights, and specialized tools, PPE is mandatory.