Pyrolon CRFR Secondary FR Gown/Smock – Rear Entry

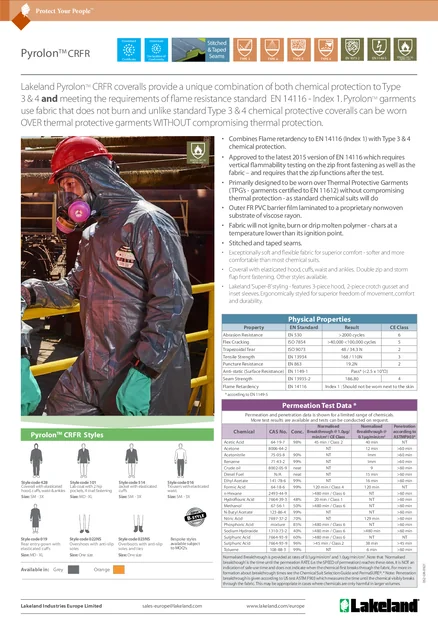

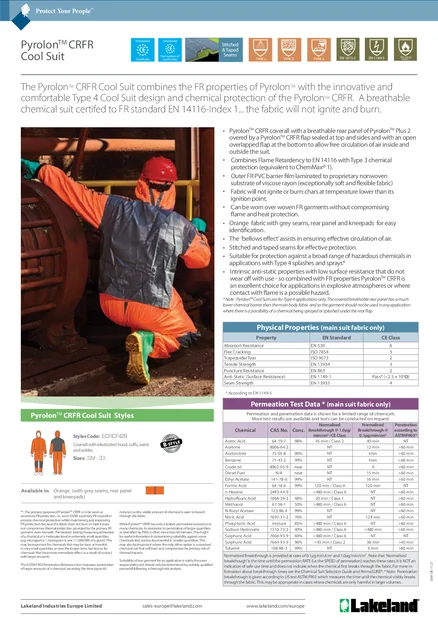

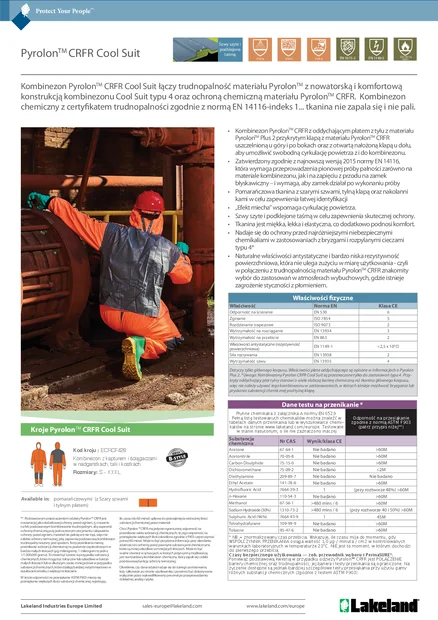

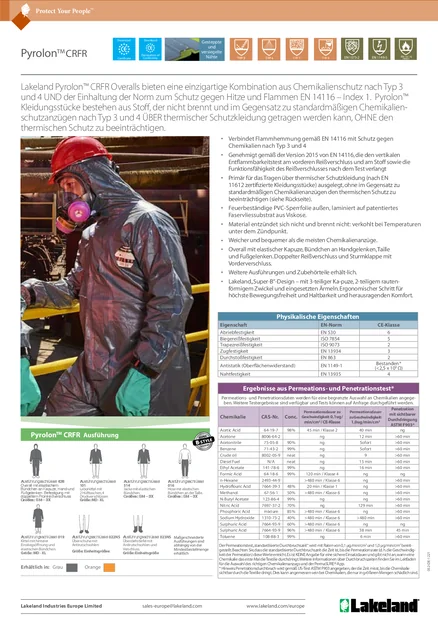

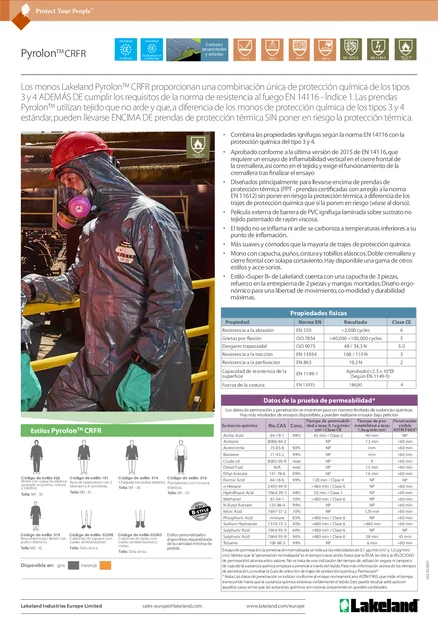

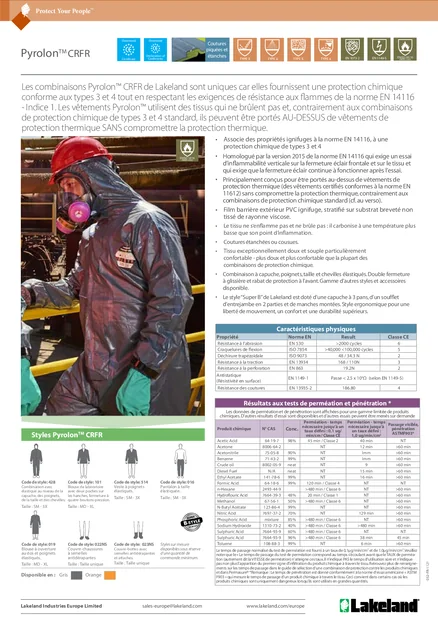

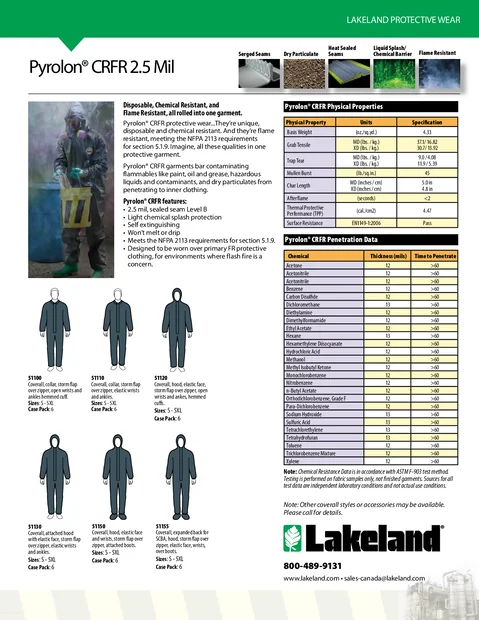

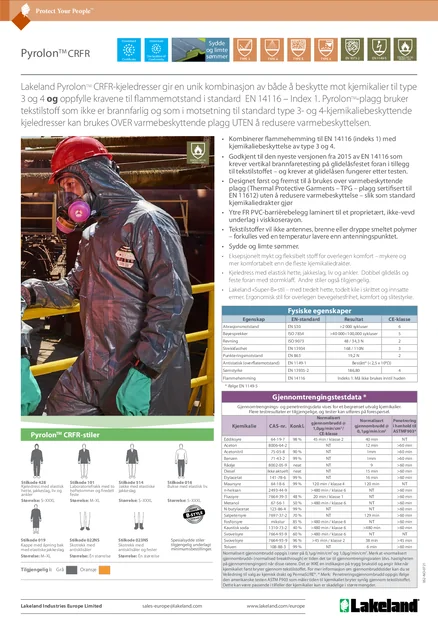

Rear entry gown with elastic cuffs and waist ties. Pyrolon‚® CRFR is a unique fabric using an FR PVC barrier film laminated to a viscose-based nonwoven substrate. The result is a soft and flexible fabric offering both chemical barrier and resistance to ignition. In contact with flame it does not ignite, melt or drip molten debris so can be safely worn as secondary FR clothing over primary FR workwear to provide chemical protection without compromising flame and heat protection. In fact thermal mannequin testing indicates overall thermal protection is improved. Certified to FR standard EN 14116 (Index 1: fabric does not ignite, melt or drip molten debris. Partial Body EN Type 3[PB] liquid jet spray and Type 4[PB] liquid spray protection. Certified to EN 1149-5 for static dissipative garments. Note: This garment does not provide protection against flames and heat when worn alone but is designed to provide chemical protection when worn over primary FR clothing without compromising heat and flame protection.

Additional information

| Garment Type | Glove |

|---|

- Available in these sales regions: Africa Sales Region, Asia Sales Region, Central America Sales Region, Europe Sales Region, Oceania Sales Region, South America Sales Region