EN 1149 is well known as the standard for anti-static garments and most users of disposable and chemical protective safety clothing specify certification to it as a requirement.

However, as with many standards – and particularly so in this case – few people understand what it’s actually telling them or the details within it. Given its importance in some applications, misunderstanding this standard could be catastrophic. In this blog, I’ll explain its contents and what it means. For additional tips on how to optimize anti-static properties of protective clothing, see our blog: “The shocking truth about anti-static safety clothing”.

There are three areas where anti-static garments are important:

- In applications taking place in or involving explosive, inflammable atmospheres or dusts. This is important because if static is not controlled, a discharging spark could result in ignition an an explosion of flash fire.

- In applications involving sensitive equipment or products (such as computer chip manufacturing)

The issue here is that a static discharge could result in critical and extremely costly damage to components. - In some specialist and high-end paint-spraying applications

Static charge build up can cause problems for achieving a high-quality finish.

Clearly, these applications show that anti-static properties are critical; in the second and third, the consequences of not getting it right could be very costly in financial terms, while in the first, the financial cost of error might well be dwarfed by the possible consequences to life. With this in mind, it’s surprising how poorly the standard is generally understood.

What does certification to the anti-static standard mean?

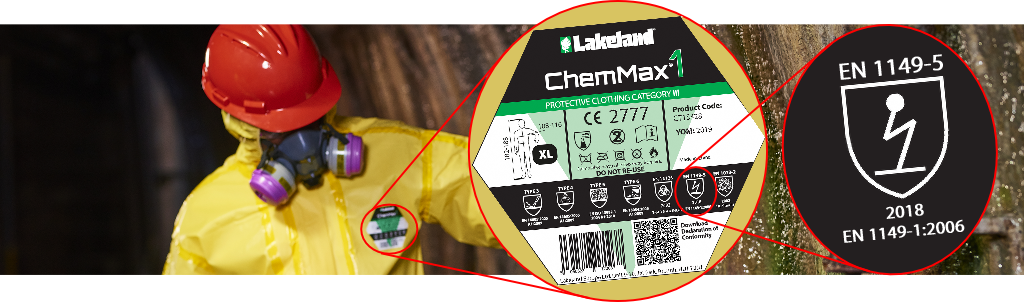

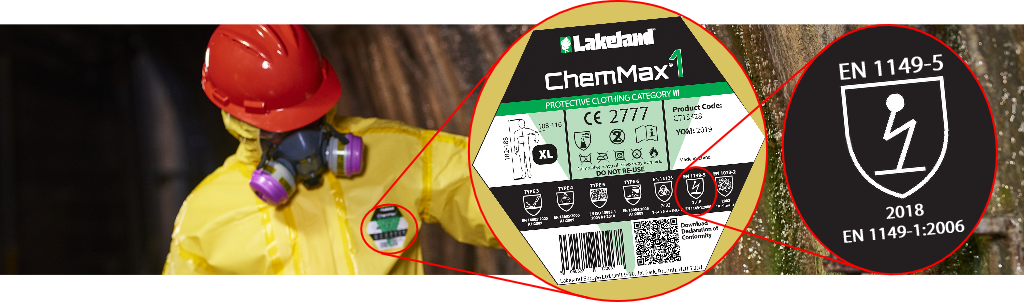

Certification to EN 1149 is indicated on a garment label by inclusion of the pictogram shown to the right. Please note, the pictogram should include the standard number with Part 5 indicated.

An electrical charge is always searching for a route to earth and will always take the path of least resistance. If no direct route is available, once the combination of charge strength and distance to an oppositely charged object is sufficient, (as this will allow it to overcome the resistance in the atmosphere), it will jump through the air to another object where an easier route is on offer. The manifestation of this is a spark which could ignite an explosive atmosphere or damage sensitive equipment.

The purpose of the anti-static standard is to reduce the possibility of a static spark. It does this by providing an easy route for the charge to go to earth without it having to jump to another object. However, it’s important to realize that the standard does not address a garment’s tendency to generate a static charge. Instead, it tries to ensure that if a charge is generated, it cannot develop to the point where a spark is generated because it can easily go to earth.

This is particularly problematic for disposable garments which are invariably made of synthetic, plastic fibers (an exception is Pyrolon garments which are intrinsically anti-static). These garments have a high tendency to develop a static charge and have poor conductivity, thus preventing an easy route to earth and resulting in a high probability of producing a static spark. (We have all experienced this with normal clothing made of synthetic fibers such as nylon or polyester).

So the objective of the standard is to measure and ensure a garment fabric has a sufficiently high conductivity (or alternatively, sufficiently low resistance – the other side of the same coin) to allow a static charge to dissipate and go to earth without having to jump to another object in the form of a potentially incendiary spark.

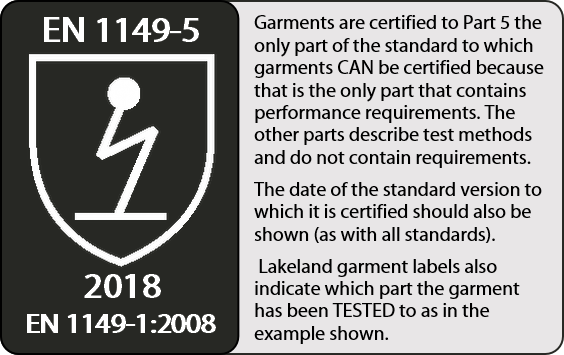

What does the EN 1149 standard contain?

EN 1149 consists of 5 parts (or rather 4 parts because part 4 does not yet exist). These are detailed in the panel below:

There are four important points to note about the standard:

- It is only Part 5 that contains performance requirements. Garments are therefore certified to EN 1149-5. They may be tested according to parts 1, 2, 3 or 4 (if 4 existed), but can only be certified to Part 5.

- Certification to Part 5 of the standard requires testing EITHER to EN 1149-1 (Surface Resistance) OR to EN 1149-3 (Charge Decay). These tests measure two aspects of the same property:

-

- Part 1: Surface Resistance: how effectively the fabric surface resists dissipation of a charge (or alternatively, how effectively the fabric conducts a charge). This indicates the charge will dissipate and not develop to the point where it can generate a spark

-

- Part 3: Charge Decay: how quickly a charge measured at a point on the fabric decays as a result of it dissipating across the fabric surface. This again indicates that the charge will not develop to the point where it might generate a spark

- The Part 5 requirements for testing according to Part 1 state it should be achieved “on at least one surface”. In other words, the surface resistance requirement of a maximum of 2.5 x 109 Ohms can be achieved on either the inside or outside of the fabric but does not need to be achieved on both.

- The vast majority of disposable coveralls and chemical protective clothing are tested to EN 1149-1, Surface Resistance, simply because of the way that anti-static properties are achieved on such garments.

Other requirements in the standard

Part 5 also details other general requirements for the design of a garment as well as the testing requirements. These include:

- The clothing should completely cover any non-compliant clothing worn underneath during normal movement, such as bending or crouching.

- If the clothing consists of multiple layers (such as in the case of fire-fighters gear), the outer layer should be anti-static and completely cover the inner layers.

- Any non-anti-static fittings (such as the zip) should be covered in use by the compliant materials (such as with a storm flap).

- Garments must be earthed via the body of the wearer or directly via an earthing cable or similar.

This last point is critical; electrostatic dissipate clothing that relies on maintaining a low surface resistance (again, allowing a charge to dissipate) will ONLY work if the clothing provides some route for the charge to go to earth. Unless such a route is enabled then the fact that the garment is EN 1149-5 certified is entirely irrelevant. It’s not a static dissipative garment and it’s not anti-static.

This highlights a point that is important in this and every other standard. In the case of EN 1149, the danger is that users simply assume that because a garment is certified to it, that garment is anti-static and therefore will not cause a spark. This is simply not the case for the following reasons:

- Just because a garment is EN 1149-5 certified and its fabric has a surface resistance below 2.5 x 109 doesn’t guarantee that it will not generate a spark under any or all circumstances. Whether a spark occurs is dependent on several factors; it’s simply not the case that a surface resistance of 2.49 x 109 will NOT result in a spark whilst one of 2.51 x 109 will. There is an unavoidable uncertainty about the conditions under which a spark may occur and this standard can only provide guidance, not a guarantee.

In critical or high risk applications therefore, use of clothing should be determined and approved by a qualified safety engineer.

- Electrostatic garments will ONLY work if the garment is earthed in some way; without a route to earth the anti-static properties of a garment are useless.

- On most disposable coveralls and limited-life chemical suits, anti-static properties are achieved by the application of a topical treatment on the fabric surface. This works by absorbing moisture from the atmosphere, creating a thin film on the surface which, being conductive, reduces the surface resistance, enabling it to meet the requirements of the standard. The fact that this is a topical treatment has several consequences for those dealing with higher risk environments:

- It may rub off with wear.

- It may degrade over time.

- It will be more effective in humid atmospheres but less effective in very dry atmospheres (because less moisture is available for it to absorb).

Like with most standards, simply using the fact a garment is certified to the standard as evidence of suitability (and without looking at the detail of the standard) can be dangerous. Other factors might mean that certified static dissipative clothing may or may not be suitable for your circumstances; other action may be required to ensure the clothing acts as you need it to (such as ensuring a route to earth is available). In any given application, the higher the risk of ignition of an explosive atmosphere or likelihood of damage to sensitive equipment, the more attention must be given to assessing the detail of the standard, the application, the task and the environment.