Industrial workplaces present challenges that are unlike many other job sites. From extreme weather exposure to operating sophisticated machinery, demanding physical tasks, and hazardous particulate exposure – selecting the correct protective garments is essential to providing optimal protection, comfort, and support for employees.

Protective Clothing Protection vs. Comfort

When selecting protective clothing, the level of barrier protection often takes precedence over comfort. There are many factors that may contribute to the selection process, including compliance and providing the highest level of protection from hazardous materials in a work environment. However, comfort is just as much a key factor in keeping workers happy and operating efficiently, as it is in the overall safety of the wearer. The fact is when employees are uncomfortable, and a garment is worn in such a way that its effectiveness is compromised, exposure risks increase.

Often personal protective equipment (PPE) or disposable protective apparel is thought to be uncomfortable because the fabric or material doesn’t breathe. For the wearer’s safety, materials that make up the items worn should be impermeable (or slow to penetrate) to avoid the risk of exposure to dangerous materials in their work environment.

When selecting apparel with comfort in mind for wearers, it is essential to choose the right level of protection for the job in hand. Depending on the potential risks for light or strong liquid hazard exposure and other environmental factors, selecting the wrong garment may not only result in unnecessary cost but also creates a less comfortable working environment. Uncomfortable protective garments may affect an employee’s state-of-mind, ability to regulate body temperature (or manage heat stress), maneuverability, and productivity.

Here are a few considerations in regard to the selection of disposable protective apparel and breathability:

Moisture Vapor Transfer Rate:

One attribute in which fabrics are evaluated is their moisture-wicking ability. Referred to as the Moisture Vapor Transfer Rate (MVTR), this analysis is measured in grams per square meter per 24 hours (i.e., referring to how many grams of moisture can pass through a square meter of fabric in a 24 hour period).

“Breathable” implies that a material is moisture vapor permeable; however, it does not relate to the exchange of air. A better way to describe the “breathability” of a protective garment is through moisture vapor permeability (MVP) or moisture vapor transmission (MVT), both of which are measurements that reflect a fabric’s ability to transport water vapor from the body.

Particularly with disposable and chemical protective clothing, MVTR and MVT are important considerations because they refer to a garment’s “moisture wicking” effect or sweat evaporation; however, these measurements only help gauge how much moisture can “escape” from a garment. They aren’t a measurement of the potential amount of “fresh air” coming into the garment.

Air Permeability:

Protective clothing shields the body from harsh exposures like chemicals, mechanical hazards, weather conditions and more. Another protective clothing consideration is air permeability and the wearer’s ability to maintain thermal balance.

Air permeability is measured by rate of airflow in cubic feet, per square foot of sample area per minute (CFM). The higher the CFM, the more breathable the garment. While “breathable” implies added comfort, the description also implies that the garment is more susceptible to permeation – a critical feature for wearers of protective clothing.

Actual Breathability Differences of Protective Apparel:

Considering that a CFM of zero has no breathability, the breathability difference in materials used for most chemical protective clothing, when compared side by side, is typically so small that the difference is insignificant.

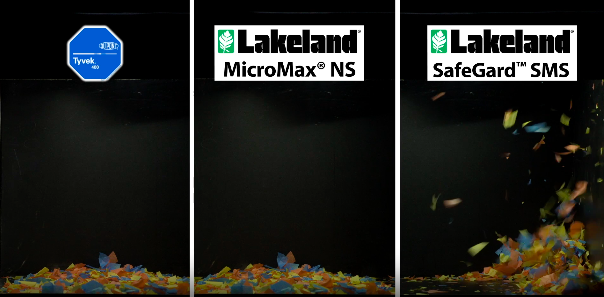

Lakeland’s SafeGard® SMMS is an ideal option for industrial applications that require protection from numerous dry particles, aerosol mist, and light liquid hazards. SafeGard SMMS garments can be used in work environments where hazardous or non-hazardous contaminants may be present and features three tough layers to keep contaminants out. The two outer layers are made of spunbonded polypropylene filaments that stand up to tearing and abrasion, while the inner layer is melt-blown polypropylene microfibers that filter out potentially harmful particulates and liquids. As shown in the video above, Lakeland’s Safegard SMMS has unparalleled breathability in comparison to other protective wear alternatives.

Do you work in an industrial setting that requires disposable protective apparel? If you’re looking for an innovative option that provides both the protection and comfort needed on the job site, learn more about SafeGard SMMS by Lakeland.