One question I often regularly receive is about the “heat tolerance” of our Pyrolon garment fabrics. The question suggests a great deal of confusion about the subject of heat protection, so in this blog I’m going to explain heat tolerance and protection to clear up any confusion.

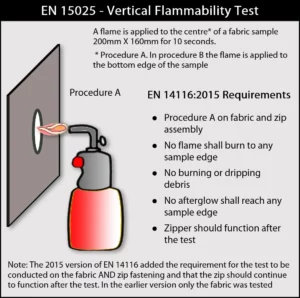

Lakeland’s Pyrolon garments offer a range of chemical protection through Types 3 to 6. These garments use fabrics that meet the requirements of FR standard EN 14116 and are tested according to the vertical flammability test EN 15025.

However, it is important to note that the purpose of this test is not to indicate a garment’s level of protection against heat or flames, but rather to indicate that the garment (and, in the latest version of the test, its components) will not ignite, propagate flame or drip molten debris.

The vertical flammability test (EN 15025) is for secondary FR garments. These garments are designed to be worn over primary FR garments (i.e. garments certified to EN11612) and provide chemical or other protection without compromising the thermal protective properties of the primary FR garment.

The questions that come up periodically relating to these products, What is the heat tolerance of the fabric?” and “What temperature will this fabric stand”? both suggest confusion about heat protection because they focus on temperature.

In reality, temperature is largely irrelevant or is, at best, a relatively minor factor in assessing heat protection and what causes skin burns.

What causes skin burns?

Skin burns occur because skin cells cannot handle rapid changes in skin temperature. Leaving aside the specific temperature, a 10oC rise over 10 seconds may not cause a burn, but the same rise over 1 second probably will. Whether a burn occurs or not relates specifically to how much heat energy is transferred to the skin over time; the more heat energy transferred in a shorter time, the greater the probability of a burn and the more serious the burn will be.

So the important issues are not what the temperature of the heat source is but how much heat energy it contains; the amount that will be transferred to the skin; and over what period.

For example, a very small heat source at a relatively high temperature contains little energy, so, with contact or close proximity, little energy will be transferred to the skin (which is why you can pass your hand through a candle flame momentarily without being burned).

On the other hand a large, concentrated heat source at a relatively low temperature – but higher than the temperature of the skin (the differential between skin and heat source is also important) –may cause a burn because it contains much more energy to be transferred in a shorter time.

The purpose of heat protective clothing is to prevent or slow the transfer of heat energy from the heat source to the skin.

Considering this, the “heat tolerance” of a fabric or the temperature of the source becomes unimportant. The real question is: “how effective is the fabric at preventing heat energy being transferred through to the skin in a given situation?” (the “given situation” will indicate the type of heat energy transfer: radiant, convective, contact and so on).

Burning Pigs and Sailors

The principles that established the calculation of whether a skin burn will occur or not were develop by Alice Mary Stoll whilst working for the US Naval Air Development Centre in the 1960’s. Extensive work was conducted to identify the relationship between heat energy transfer and time, resulting in the establishment of the “Stoll Curve” – a simple mechanism to predict the combination of heat energy transfer and time that will result in a 50% probability of a 2nd degree burn occurring. This calculation is still used today as the basis for burn prediction.

The work reputedly used experimental burning of the skin of pigs and sailors. The sailors were volunteers but were rewarded with extra shore passes. It’s reasonable to assume the pigs were not however, volunteers!

What exactly is “heat tolerance?”

One problem is not understanding what the questioner means by the term “heat tolerance”. I fear in many cases it is being used as a way to ask:

“What is the maximum temperature against which this fabric will protect?”

If this is the case, then it’s a meaningless question and any answer given is also meaningless. This is because protection relates less to temperature and more to heat energy transfer. The answer, ultimately, is entirely dependent upon the heat energy an object (say, a furnace) contains, how close you are to it, and for how long. If this was a relevant or meaningful question, I could happily and confidently answer with:

“Oh, this fabric has a tested “heat tolerance” of over 30,000oC.”

Of course that would be a ridiculous and irresponsible claim… and yet it would be entirely true. The heat source in this case would be the sun (the surface of which is around that temperature) and the proximity to it is 93 million miles (give or take a few). The test involved standing outside in the sunshine wearing the suit and I could quite happily confirm the test subject suffered no burns…

However, what users may sometimes mean is: “what is the melting point of the fabric?”. Though the question is more specific, in terms of heat protection it is also largely irrelevant for two reasons:

- A fabric may have a melting point at XoC; but at the same time, it may soften, decay or otherwise change its properties at a temperature much lower than XoC.

- If a fabric has a melting point of 252oC (as is the case with Pyrolon garments), it will not melt until it reaches that temperature. In fact, it has little relevance in terms of any heat protective properties or how the garment is used.

If heat tolerance and temperature are irrelevant… what actually matters?

So when I am asked an apparently simple question like this, I am always concerned by what the thinking behind it is and I am loathe to give a simple answer because, in truth, there isn’t one.

When assessing heat protection, the temperature of a heat source or the “heat tolerance” of the fabric is probably the least important question. What you should be considering when it comes to the selection of protective clothing are the following:

- The type of heat energy (radiant, convective, contact etc)

- How much heat energy a source contains and how much may be transferred to the wearer. This will relate to:

- Proximity to the source

- Duration of exposure

- Finally, how effective is a fabric or garment at resisting or preventing the transfer of heat energy from the source to the skin of the wearer? Information on this can be found by looking at the heat energy transfer tests contained within EN 11612 to which a garment has been tested or by considering any Thermal Mannequin testing conducted to indicate predicted body burn.

Conclusion

Protection against heat and flame is a complex issue and it is important to understand that questions such as “what is the heat tolerance of this fabric?” or “what temperature will this fabric protect against?” are largely irrelevant. These questions have no simple answer and not only are they meaningless questions, they are, quite frankly (along with any simple answers you may be given as answers) literally nonsense.