EN 1149 is the standard for “anti-static” or “static dissipative” clothing. And while well known and a common requirement for disposable chemical protective clothing through Types 1 to 6, understanding of what it means, how it works and especially its shortcomings is often limited.

Misunderstanding standards can have serious consequences – consequences that in this case could be catastrophic.

This blog considers common questions and issues pertaining to anti-static safety clothing, providing users and safety managers with a better understanding of this important standard and offering useful tips to ensure clothing used in your environment is actually suitable.

Why is “Anti-static” Important?

Many types of protective clothing, whether single or multi-use are manufactured with synthetic fibers… polyester, polypropylene, polyethylene and so on. Such synthetic materials have a propensity to develop a static charge during movement of the wearer.

Because these materials are feature low conductivity (i.e, they cannot conduct a charge effectively but tend to hold it in a localized area) a charge will tend to build over time. All electrical charges will go to earth if possible and at some point, once the charge is strong enough and when the fabric comes into close proximity with another oppositely charged surface (such as a workbench or door handle) it will discharge suddenly with spark.

In many industrial applications an electrostatic discharge (ESD) such as this can be a problem. For example

- An explosive atmosphere, chemical or dust could be ignited with devastating consequences

- In some manufacturing of sensitive electronic equipment it can seriously damage product

- In high quality paint spraying it can compromise the paint finish.

As a result avoiding a potential static spark when a charge builds up on protective clothing is vital – failing to address the issue could have consequences that range from ruining the job, destroying expensive equipment or product or in the worst cases, causing major explosions or fires.

What Does Anti-static Clothing Actually Mean?

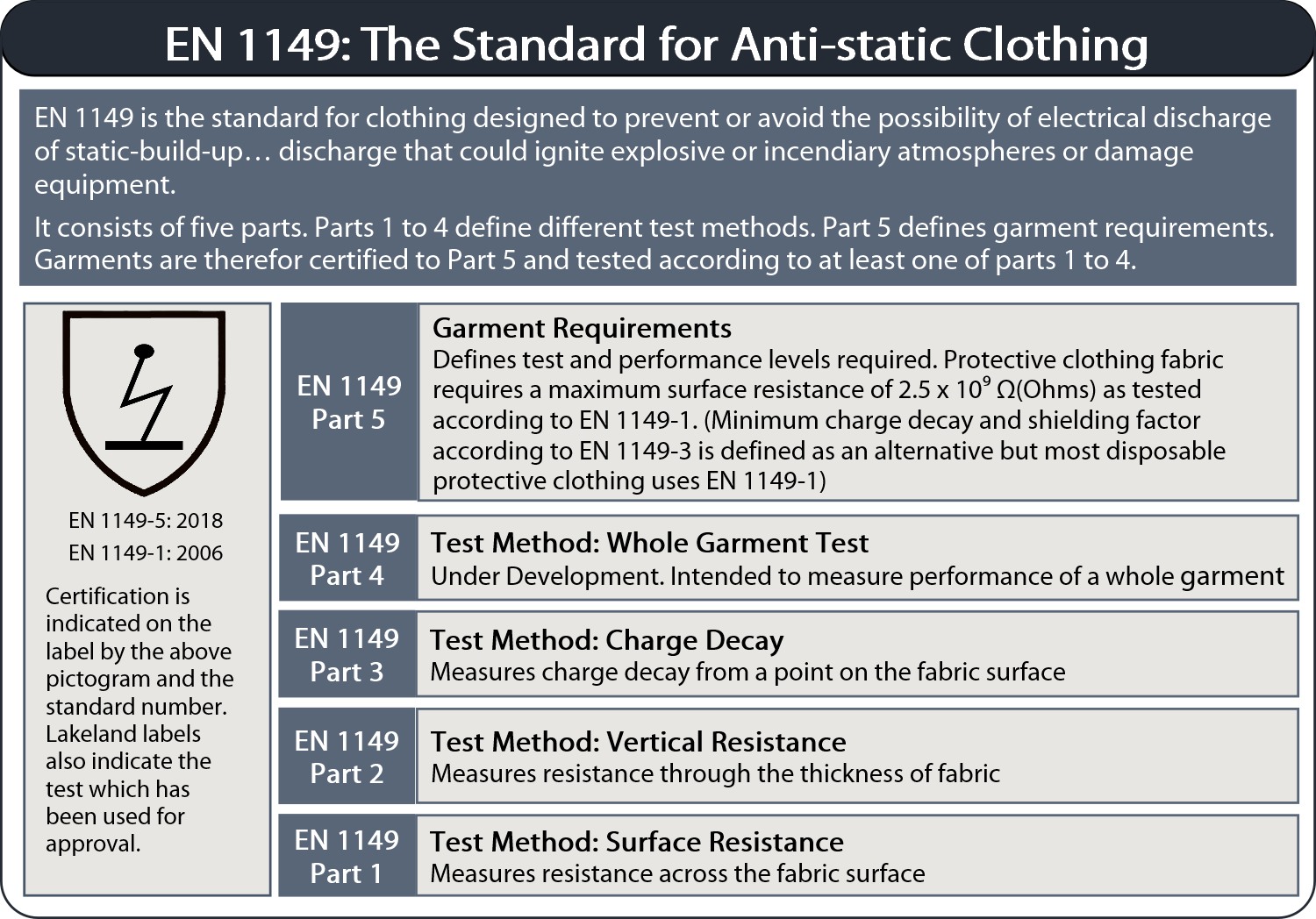

In the context of protective clothing the objective of “anti-static”, as identified by the pictogram in the table below, is to ensure incendiary or damaging such ESD sparks are avoided. “Anti-static” literally means to avoid static sparks.

How are “Anti-static” Properties Achieved in Protective Clothing?

Given the common presence of synthetic materials the development of a static charge with movement is unavoidable and the tendency to “go to earth” in some way cannot be prevented. The solution is to provide an easy route for any static charge to go to earth – or “dissipate” easily and without generating potentially harmful sparks. To do this the naturally low “surface conductivity” of the fabric must be increased, or, by the same token, the naturally high “surface resistance” must be reduced.

|

Conductivity or Resistance? “Surface conductivity” is the tendency of a material to conduct a charge across its surface. “Surface resistance” is a fabrics tendency to resist that charge being conducted across its surface. They are two sides of the same property… |

So the objective is to ensure the fabric surface resistance is sufficiently low to allow any charge to “dissipate”… to conduct across its surface and go to earth harmlessly. So how is this achieved?

There are two types of Anti-static Clothing using different methods:-

Woven Anti-static Clothing

Clothing with Anti-static Coating or Treatment

However, disposable coverall and chemical suit fabrics such as Lakeland’s MicroMax NS Type 5 & 6 coveralls are based on “nonwoven” materials. That is, they are not woven but pressed and bonded into a fabric form, so this method is not easily possible. The solution – one that is employed for all fabrics used for disposable coveralls of all types – is achieved at the stage of fabric, not the garment, manufacture.

Essentially an “anti-static treatment” is applied to the surface of the fabric, normally through the use of a spray applied across the whole surface, or by feeding the fabric through a roller bath containing the treatment.

How Do Anti-static Chemicals Work?

Anti-static chemical treatments consist of a hydrophilic surfactant which attracts moisture. When exposed to the air (i.e., when the suit is put on and used) it absorbs moisture from the surroundings, creating a thin layer on the surface. Moisture is of course conductive, so this provides a conductive “film” across the surface of the coverall, effectively lowering the surface resistance and allowing any charge to dissipate and go to earth harmlessly. A simple, yet elegant solution.

Thus, the term “anti-static” for clothing treated in this way is a misnomer as this term really means preventing a build-up of a static charge. The more correct term for this type of clothing is “static dissipative” – the property of allowing a charge to dissipate and go to earth without generating any sparks.

So what, given the title of this blog, is so shocking about anti-static clothing?

To understand this we need to consider the factors that affect anti-static properties…

Factors that Affect the Anti-static Properties of Garments.

Most users understand the need for “anti-static clothes” – yet often without a clear understanding of what it actually means and how different factors can affect performance.

A Sliding Scale of ResistanceIn fact, before the existence of the EN 1149 standard (or the similar standard for North America) there was no clear definition of what level of resistance constitutes “anti-static”. The reality is, that, in terms of surface resistance, there is no absolute dividing line between “anti-static” and “not anti-static”. Rather it is a sliding scale of resistance… the lower the resistance, the greater the probability that a build-up of static charge will not result in an electrostatic discharge because it can more easily dissipate to earth. Whether it does or not however may be influenced by other factors in the environment. For Europe the EN 1149 standard has established that, at least legally, the definition is a garment fabric with surface resistance no greater than 2.5 x109 Ohms, as defined in Part 5 (see panel above). A surface resistance lower than this means the garment is “anti-static”. Higher, and it is not. However, this definition is a minimum performance level and does not necessarily mean that a garment is suitable in your specific application which could involve factors requiring a level of surface resistance lower than the maximum that the standard defines. |

However, once an understanding of how these anti-static – or rather dissipative properties are achieved, the factors that influence its effectiveness, along with it’s limitations, problems and potential pitfalls for users become apparent:-

- This is a topical treatment with an anti-static chemical applied to the surface of the fabric at the stage of fabric manufacture.

It is therefor quite possible that this treatment could rub off or fade in some areas of the fabric during use. As a result the treatment applied in the manufacturing process is not necessarily present to the same level at a given point of use.

- The treatment works by absorbing moisture from the atmosphere surrounding the suit.

Thus it will be more effective in atmospheres with high humidity (because there is more moisture to draw on) and less so in low humidity. In very low humidity, in fact, it may not work at all.

The EN 1149 standard addresses this by requiring fabric samples to be preconditioned for 24 hours in a controlled relative humidity of 25% – which realistically is very low and unlikely in most normal circumstances.

It is worth noting however that if a work environment has very low humidity for any reason, then dissipative properties of disposable safety clothing may be very poor.

- The time between manufacture of fabric and the use of a garment might be months – perhaps even years if large stocks are maintained by convertor, distributor or end user.

Does an anti-static treatment fade over time while a coverall remains in storage?

There are no recent studies addressing this question. The answer may relate to whether garments are packed in sealed bags or not (some garment bags are simply sealed with tape). Age of garments and type of packaging is thus a point worthy of consideration.

- In less critical environments disposable garments are commonly re-used if uncontaminated and undamaged.

The longer a garment is used the greater the possibility that dissipative treatments are eroded and dissipative properties reduced. Garments may also be subjected to cleaning, wiping down or to decontamination showers. Any such process is likely to remove the anti-static treatment so that the garment is no longer anti-static.

- The treatment works by enabling dissipation of a charge to earth without any sparks.

However, that relies not only on the fabric surface resistance but on the existence of a route to earth. Often that is through the body of the wearer, but if a user is wearing insulating clothing under the coverall that prevents contact of fabric with skin, if the user is wearing insulating footwear or if there is no other easy route, the charge will build anyway and eventually could result in an electrostatic discharge.

The conclusion can only be that in the real world “anti-static/dissipative” or “not anti-static/dissipative” is not a simple question. Especially in more critical areas the real question is not “Is this coverall dissipative?” but “Is this coverall sufficiently dissipative for my application?”.

Below are five tips to help answer this question and manage anti-static clothing more effectively in order to minimize the risk of ESD.

Five Tips for Safety Managers to Ensure Anti-static Garments Work Effectively.

1. A risk assessment should ask the question “how critical are anti-static properties?”

In other words, what are the consequences of clothing NOT being sufficiently dissipative?

If an errant spark is generated what might be the result? Minor damage? An inconvenience? Or a major explosion or fire in an explosive or incendiary atmosphere that could result in serious injuries, deaths and serious damage to plant?

If the latter, clearly much more attention needs to be paid to ensuring clothing is sufficiently anti-static… and only EN 1149 certification may not be enough.

2. Ensure garments are always earthed

Regardless of fabric dissipative properties, if there is no actual route to the ground, a static charge will build and may result in a potentially dangerous spark anyway.

There are three possible ways to transfer static charges to earth:

- Through the body of the wearer

Commonly the simplest route is through the body of the wearer (the human body is roughly 60% water… we are good conductors!). However, this requires that the charge can pass from the coverall fabric to the body – so ensure that some part of the fabric remains in contact with the skin of the wearer and that a charge can pass from the wearers body to earth… so for example, avoid insulating footwear.

- Through garments with attached socks to ensure constant contact with the floor

Wearing conductive overshoes or boots that maintain contact with both the coverall and the floor will ensure a route to earth is maintained. Even more effective are garments with socks or booties attached (worn outside the wearers normal footwear), so that the coverall itself maintains contact with the floor. (This of course assumes the floor is conductive and not insulated. If the charge cannot go to earth through the floor this will evidently not work).

- Through a conducting cable clipped both to the anti-static clothing and a known grounding point

In some circumstances, especially in more critical environments, a conducting cable with one end clipped to the dissipative clothing and the other to a known grounding point can transfer static charges to earth harmlesslyHowever, even with the above routes accounted for, it is crucial that the earthed point or contact has a sufficiently low resistance to allow electric charges to go to ground.

3. Consider and even control the humidity of the environment

The EN test for surface resistance (EN 1149-1) is conducted in a relative humidity of 25%, which is very low – specifically to make the challenge greater for the surface treatment because less moisture is available to create the conductive film. The good news is that in real world environments the humidity in most cases will be much higher than this so the anti-static treatment is likely to be more effective (i.e. the surface resistance lower) than indicated by the test.

However, in extreme cases where anti-static is more critical, or where a dry atmosphere is common it may be prudent to monitor relative humidity to ensure it remains high enough to enable effective operation of the dissipative coating on the fabric. Where possible, it may even be worthwhile considering controlling humidity through the use of humidifiers to maximize the effectiveness of dissipative properties

4. Limit usage, don’t re-use garments and check them regularly

Continued use of dissipative garments – particularly in environments where abrasion is a concern – could degrade anti-static functionality. If anti-static garments are used for extended periods of time, changing to new garments regularly is advised as the anti-static treatment may fade or rub off. Suits should not be re-used and should never be cleaned, wiped down, washed or subjected to a decontamination shower. Any such washing or decontamination is likely to remove the anti-static treatment.

Where garments must be used for extended periods, a method of checking and monitoring surface resistance over time might be appropriate to ensure dissipative properties are maintained (simple hand-held surface resistance measurement devices are readily and quite cheaply available).

Remember however, the results of such monitoring will vary with humidity so may change from one day to the next – and the test used in the EN 1149 standard is conducted at RH 25% – so unless an in-use test is conducted in the same humidity the result will be different anyway. The point of such testing would be to confirm dissipative properties are not degrading over time rather than to confirm if the fabric continues to meet the EN 1149 standard requirements.

5. Finally, in the most extreme applications – such as in highly flammable atmospheres – relying solely on garment certification to EN 1149 may not be enough.

- Develop an understanding of the likelihood of any electrostatic discharge and its consequences

- Consider the value of specialist advice to identify the level of garment static dissipation you should maintain

- Ensure effective grounding procedures and affective suit management as described above.

The Relevance of ATEX

It is worth noting that the ATEX regulations relate to equipment – switches, machinery, tools etc – but not clothing. In fact ATEX specifically excludes certification of clothing to it.

|

The ATEX acronym is derived from “Appareils destinés à être utilisés en ATmosphères EXplosives” – French for “Equipment Intended for use in Explosive Atmospheres” |

It does however state that clothing used in any ATEX zone should at least meet the requirements of EN 1149-5 as assessed by EN 1149-1 and that this is the best indicator for clothing for use in such environments. Note, however, the use of the term “AT LEAST”. In other words, just meeting EN 1149 requirements might not be enough.

In the final analysis relying on simple disposable clothing with topical anti-static properties that can erode in some circumstances might not be enough and specialist dissipate clothing may need to be considered.

For example, the Lakeland Pyrolon® range of protective clothing is primarily designed for combined FR and chemical protection and available in versions for chemical protective clothing Type 3 to 6. Pyrolon® is manufactured with a unique fabric not primarily based on synthetic fiber and containing a naturally high moisture content and consequently intrinsically low surface resistance that does not rely on any topical treatment. Pyrolon can therefor be a safer choice in environments requiring anti-static or dissipative clothing.

Ultimately, and especially in more critical environments, a better understanding of the anti-static standard and how dissipative properties are achieved is a useful addition to the tools available for Safety Managers handling garments in areas where potential static discharge is a hazard.

By following the points outlined in this blog, a safety manager can develop a more effective approach to the provisioning of anti-static PPE and ensure they provide the right protection for both the worker and the workplace.

You can access our Anti-static clothing fact-sheet here, one of many such fact-sheets freely available from our resource page.