As we have said in previous blogs and literature on our website, the CE marking is nothing more than the manufacturer’s declaration that the item in question meets minimum performance requirements concerning a specific standard.

And yet some mistakenly interpret it as meaning the item is perfectly safe for them to use, not considering the details of the testing itself or the circumstances under which they work.

In this blog, we will look at the five most common FR clothing myths and debunk them, providing you with greater clarity on testing and use of certified FR workwear.

Myth #1: Certification to EN 14116 is enough to show that all Secondary FR workwear is the same and that it is safe to use.

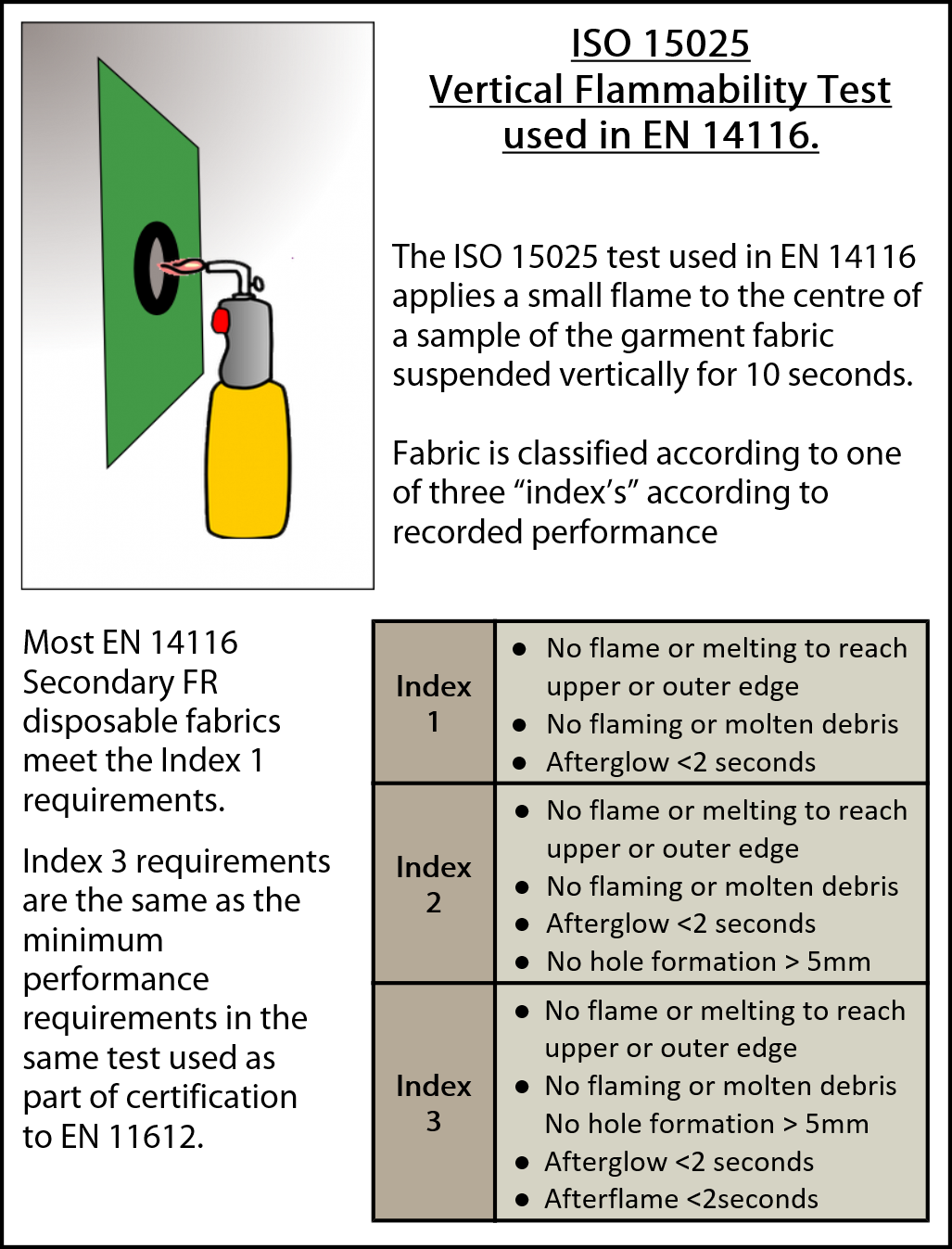

EN 14116 contains only one fabric test – the EN 15025 vertical flammability test (VFT).

The vertical flammability test is a simple method so indicate how the fabric reacts to contact with a small flame. In the case of EN 14116, the requirement is that the fabric does not ignite, burn or drop molten debris. This test is limited in that it’s in defined lab conditions and therefore a poor indicator of real-world performance – the flame is small and only applied to a piece of fabric. The expectation that, in a real-world scenario, the wearer of secondary FR clothing would stay unmoving in one place is unlikely – and in the real world, workers are more likely to be exposed to flash fire or bursts of flame (much more intense) for a few seconds.

Also, not all fabrics react to heat exposure in the same way. For example, fabrics that use synthetic thermoplastics will shrink away from the heat of the flame before contact is made, avoiding ignition through “escape” rather than any kind of FR property.

Ultimately, knowing what the standard includes in terms of testing will enable safety managers to make more informed decisions. Certification to EN 14116 is simply a minimum performance requirement, based on the above scenario. For a more comprehensive assessment, garments should be tested with optional thermal mannequin testing.

When assessed with the thermal mannequin testing to indicate just how effective workwear is, the results show major differences between secondary FR workwear types (with cheaper types showing very little difference at all from non-FR workwear).

Myth #2: All Secondary FR Workwear certified to EN 14116 have passed the same tests.

As EN 14116 only contains one test, it’s not unreasonable to assume that all workwear certified to this standard have passed the one test.

However, there are two problems with this assumption:

- The Vertical Flammability Test is intended to show that fabric will not ignite and burn. It was not designed for the type of thermoplastic fabrics that are commonly used for Secondary FR workwear. Thermoplastic materials shrink from hear and since this test applies a small flame to the center of a fabric sample, a sample can meet the requirements becuase it shrinks away from the flame quickly enough to avoid contact and therefore ignition.

- The revised version of EN 14126 published in 2015 introduced a new requirement: that the components (including front fastening assembly as well as the fabric itself) must be tested using the VFT, meet the same requirements and front fastening must continue to function after the test.

However, garments based on FR-treated SMS have been unable to meet these requirements, and yet they continue to be certified. How is this possible if they don’t meet the full requirements of the standard?

The answer is in some cases, manufacturers are allowed to certify a product to a particular standard but exclude specific clauses within it. In other words, some FR SMS garments have been certified to the new standard, but have excluded the requirement for front fastening to be functional after the test. Since this was the key change in the 2015 version, it essentially means garments are not certified to the new standard, but the old one.

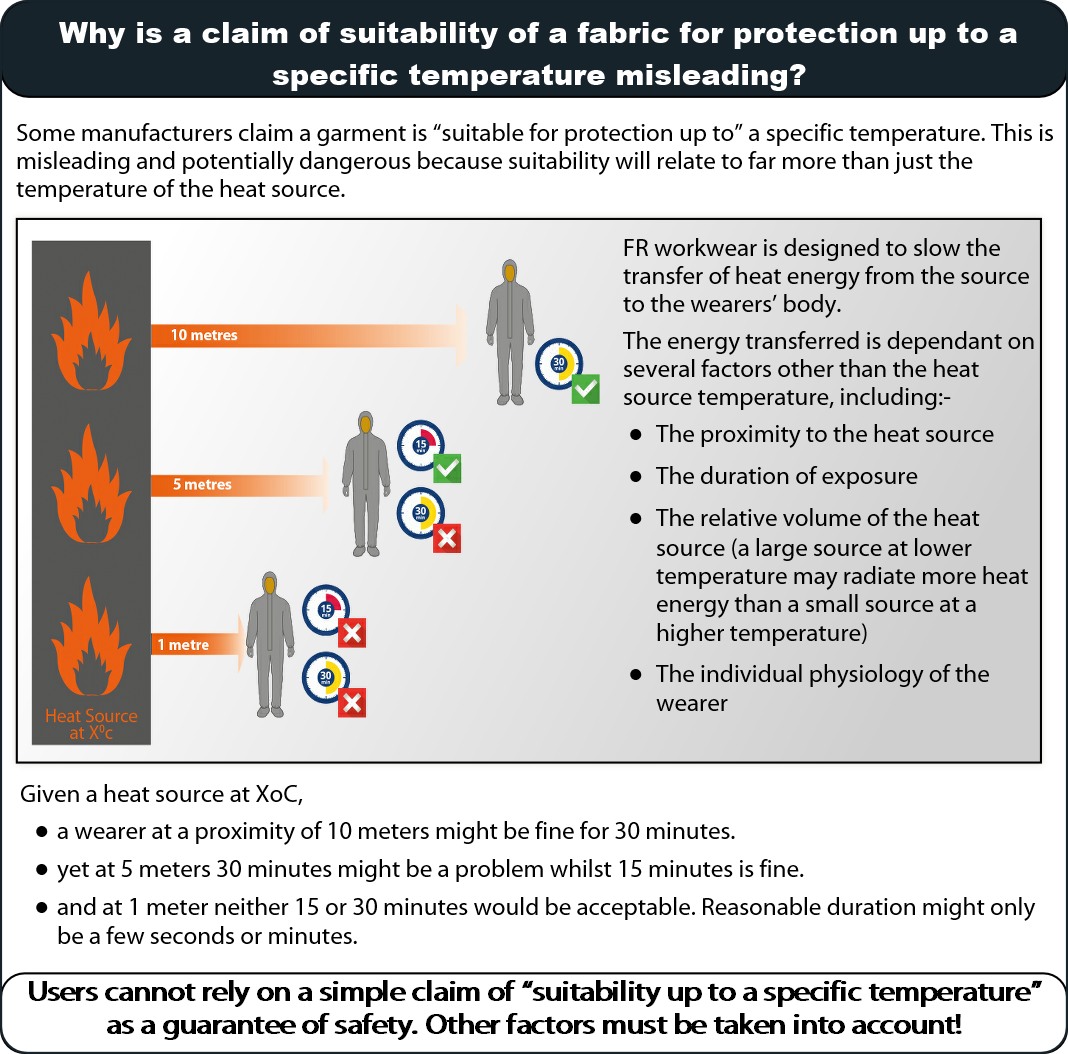

Myth #3: A manufacturer’s claim that “This garment is suitable to resist temperatures of up to 1200oC” provides information about how well you are protected.

This is not an uncommon claim by manufacturers of heat-protective workwear – and yet it is a meaningless and potentially misleading one.

The purpose of heat-protective workwear is to resist the transfer of heat energy from the heat source to the wearer’s body: if too much heat energy is transferred too quickly, the skin cannot cope and a burn results.

Yet the temperature of the heat source is a relatively insignificant factor in how much heat energy transfers. Heat energy transfer depends on a combination of several factors:

- the volume of the heat source (a larger source at a lower temperature may radiate more heat energy),

- the proximity of the worker to the source,

- the duration of exposure (10 minutes may be no problem 10 meters from the source, but in the same FR clothing 1 minute might result in burns 1 meter from the source).

So, the suggestion that a garment is suitable for protection against heat sources of 1200C does not mean that it will protect you against a specific heat source at 1200C in all circumstances. As always, the devil is in the detail and it depends on several other factors.

Myth #4: Garments certified to EN 14116 WILL protect against heat and flame. Or alternatively, garments certified to EN 14116 WILL NOT protect against heat and flame.

Both of the above statements are false, or in fact, possibly true…. Confused? That’s understandable. The title of this standard is in itself confusing: “Protective Clothing – protection against flame – Limited flame spread materials, material assemblies and clothing” – thus implying it indicates some level of protection against heat and flame.

Despite this title, most garments certified to this standard will not provide any protection against flame. The VFT is primarily designed to show that garment fabric will not ignite and burn, not that it will protect against flames.

But that’s not the whole story.

The results of the VFT are graded to three classifications or indexes – Index 1, 2 and 3. The lowest is Index 1 – to which most Secondary FR workwear is certified and whilst it confirms the fabric will not ignite and burn it does not indicate the fabric will protect against heat and flame. However, the highest level – Index 3 – requires that contact with the flame results in holing no greater than 5mm diameter which, coincidentally, is the same as the minimum requirements in the same test used in EN 11612 – the standard for clothing to protect against heat and flame.

So what does this mean? Well, it means that a garment certified to EN 14116 Index 3 meets the same minimum requirements as a garment certified to EN 11612. This means it is an indication that it will provide some protection against flame – but only if it is Index 3. Garments certified to Index 1 or 2 will not protect against flames.

A rare example of this is Pyrolon® CBFR, which whilst classified as Secondary FR workwear actually meets the requirements of Index 3 in EN 14116 (or the minimum requirements in EN 11612) and so is also certified to EN 11612 and will also provide minimal protection against heat and flames.

Myth #5: All EN 11612 garments are tested using the same tests and are essentially the same.

Whilst Primary FR Workwear garments certified to EN 11612 have met the same minimum requirements defined in the standard, this does not mean they are all the same. As well as passing the basic requirements for heat resistance and stability, all garments must be tested to at least 1 of 5 different heat energy transfer resistance tests, and achieve at least class 1 in it.

These 5 tests focus on resistance to different types of heat energy – radiant, contact, convective, molten droplets and so on – each indicating suitability for different types of application. For each result, garments are classified either as Class 1 to 3 or 1 to 4 depending on the test (1 is the lowest level).

Also, the standard offers the option of thermal mannequin testing, subjecting the garment to a simulation of a real-world flash fire and indicating how well it protects against it.

So, information on the tests conducted (and the results achieved) are important in indicating what types of applications Primary FR workwear is suitable for – and the performance level it achieves. For example:-

- Garment A might have only been tested to 1 of the heat resistance tests, achieving only Class 1) and not thermal mannequin tested at all.

- Garment B however, might have been tested to all 5 heat resistance tests, achieved the highest class in each and been subjected to a thermal mannequin test to indicated body burn in a flash fire.

Both examples above are certified to EN 11612 as Primary FR garments. On the basis of the certification alone one could assume they are roughly the same. Only through examination of the detail of the tests within EN 11612 performed on each does it become clear that they are, in fact, very different with garment B offering far superior protection.

So making an assumption that any EN 11612 garment is suitable for your application is potentially dangerous; it might not be suitable at all. In selecting primary FR workwear it is important to consider the task in hand, the type and volume of heat energy applicable and ensure a garment that has achieved a suitable standard in the correct heat energy test is chosen.

Conclusions: Understand the standards and investigate the details

In selection of any PPE it is always important to understand that standards define minimum performance requirements, so just ticking the box that confirms the PPE is certified to a specific standard is not enough to conclude it is suitable for your application.

Knowledge of the standard and the tests it includes – as well as how the tests are carried out and what they relate to – is crucial in determining the suitability of any protective equipment or safety clothing. These five myths are proof that this applies as much to FR clothing as to any other PPE – perhaps even more so. Understanding and selecting effective Secondary and Primary FR workwear must begin with a full understanding of heat protection and the detail of tests within the standards EN 14116 and EN 11612.