Any program for selection, management and use of chemical protective PPE should include an assessment of storage and disposal requirements.

Storage is important in ensuring PPE is maintained in proper condition until it is used and especially if stored for re-use. Meanwhile disposal is complicated by the possibility of chemical contamination.

This blog looks at basic requirements and considerations for storage and disposable of chemical and disposable suits with the objective of ensuring PPE is maintained in the best condition until it is needed.

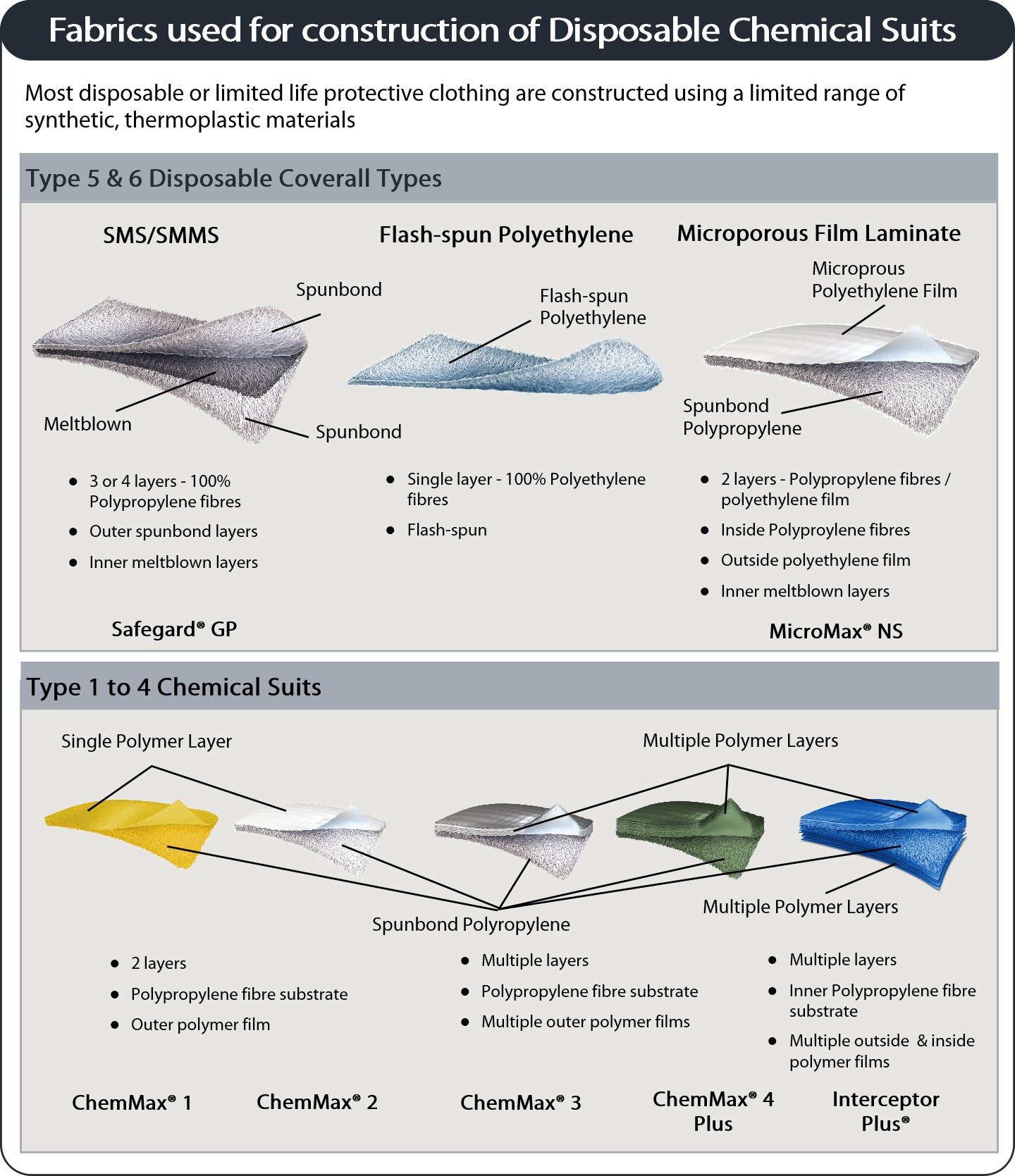

Fabrics Used for Construction of Safety Clothing

PPE storage requirements are largely dictated by the type of fabric since how the materials behave changes over time.

Most disposable or limited life clothing for Type 1 to 6 gaseous, liquid and dry particle hazard protection is manufactured using polymer based fabrics and films.

Type 5 & 6 Disposable PPE

Of the three types of fabric used for disposable Type 5 & 6 protective PPE:-

- SMS/SMMS (Safegard® GP & Safegard® 76) is constructed of 100% spunbonded / meltblown polypropylene fiber

- Flash-spun Polyethylene, known by the brand “Tyvek®” is single layer 100% polyethylene fiber

- Microporous Film Laminates or MPFL (MicroMax NS) invariably consists of two layers, the inner being spunbonded polypropylene fiber

Types 1 to 4 Chemical Safety Clothing.

Type 1 to 4 chemical protective suits (ChemMax® 1,2,3 and 4 Plus and Interceptor Plus) usually consist of an inner substrate layer of spunbonded polypropylene with either single or multiple layers of different polymer films laminated to it.

In other words, the majority of the fabrics used for chemical safety clothing are based on thermoplastic polymers – or plastics – and so are generally inert and harmless. As a result, there are no specific or unique essential storage requirements; they should be kept in cool, dry conditions and away from strong light.

You can discover more about the ChemMax® range of chemical suits here.

What are the consequences for storage and disposal of disposable PPE?

Strong light, including sunlight, is likely to result in discoloration – white fabrics especially may gain a yellow tint over time – but this is a cosmetic change and does not affect fabric performance.

As we have learned to the cost of the environment, plastics do not easily degrade and will be around largely unchanged for decades, if not centuries, so in normal conditions the shelf life of these types of garments can be measured in years. All things being equal, a ten-year shelf life should not be a problem.

The Importance of Safety Clothing Packaging

Most disposable protective clothing in Europe is supplied in individually sealed plastic bags, partly because the smallest unit of sale is often one or two garments purchased by local users through a PPE supplier industrial shop (though commonly in North America garments are supplied loose in bundles of 50, and in some cases in Europe, more basic garments are supplied in similar bulk packaging.) CE marking requires that the legally required User Instruction Sheet (in multiple EU languages) is supplied with the smallest unit of sale so packing garments in individual bags makes this an easier proposition.

Sealed bags also ensure garments are maintained in a clean and dry condition during transit; as most are made in Asia, transit generally involves several weeks storage in a container – some of which will be on the ocean. Keeping garments in their sealed bags in a user warehouse until used will also help keep them clean and dry.

However, there are other reasons why it is wise to keep garments in their sealed bags until used – such as anti-static properties.

Topical Anti Static treatments on Disposable PPE

Most disposable or limited life protective PPE is certified to the anti-static standard EN 1149. There is considerable confusion about what this actually means, but in short:-

- The need is to avoid the creation of static sparks or “Electro-Static Discharges” which can be hazardous in explosive atmospheres or where flammable liquids are present or can damage sensitive electronic equipment.

- This is achieved on most disposable fabrics by applying a hydrophilic treatment to the surface.

- This treatment attracts moisture from the atmosphere surrounding a garment in use, creating a conductive film on its surface and thus allowing any static charge to dissipate to earth without generating any ESD (provided a route to earth is made available).

Given anti-static, dissipative properties are achieved with a topical treatment applied to the fabric surface, whilst there is no evidence to show that the treatment may fade over time, it is not unreasonable to conclude that it may be affected if exposed to the atmosphere for long periods.

For this reason, if anti-static is an important issue for chemical protective clothing, then maintaining stock in the original sealed and unopened bags makes sense.

Storage of Chemical Safety Clothing for Re-use

As discussed in our blog “When is it safe to Re-use Disposable Safety Clothing“, even disposable garments are sometimes re-used, and with most chemical suits, if not contaminated or damaged there is no reason not to re-use them.

So how should garments be stored for re-use?

Again, the basics apply; ideally store in cool, dry conditions and away from strong lights. However, used garments should preferably be hung on pegs or hangers rather than re-folded. Re-folding may create creasing which can result in stresses in the fabric, creating possible weaknesses.

Again, where anti-static properties are important, re-use of garments is not advised as the topical treatment may well have faded.

Disposal of Chemical Safety Clothing

Disposal of uncontaminated garments is relatively straightforward depending on local regulations and the existence of contamination on the clothing.

Given that most safety clothing are constructed using synthetic polymers (and other components, zips, threads and so on tend to be similar materials) like most plastics they can be disposed of in a landfill or can be incinerated without harm. Given likely emissions produced in either case this is not ideal, but preferable to the plastic working its way into the natural environment. In terms of volumes, the polymers used in disposable protective PPE are very small compared to other uses of disposable products, such as cups or diapers.

Can Disposable Chemical Suits be Recycled?

Technically, as the materials are plastic, recycling of uncontaminated clothing is possible. However, the challenge comes in separating the different polymers or components to enable recycling as often different polymers cannot be processed together. The cost and energy used in doing this makes recycling unfeasible.

The Problem of Chemical Contamination of Safety Clothing

The complication with disposal comes where garments are contaminated with chemicals. Clearly normal procedures cannot take place unless the garment can be effectively decontaminated first (though where chemical may have permeated into the molecular structure of the fabric decontamination may not be possible).

Thus, disposal of contaminated garments must be determined on a case-by-case basis and in each case the decision will relate to:-

- The chemical – how toxic o hazardous is it?

- Can the PPE be decontaminated effectively (bearing in mind the possibility of molecular permeation)?

- What local regulations control disposal of the chemical or items contaminated with it?

Conclusion… The Critical Issues for Storage & Disposal of Chemical Safety Clothing

Compared to the complexity of selection and use of chemical protective clothing, issues relating to storage and disposal are relatively straightforward:-

Storage of Chemical and Disposable PPE Garments Before Use:-

- Store in cool, dry conditions away from strong light.

- Maintain in original sealed bags where available until use.

- Where needed this should result in a shelf life of several years.

Storage of Chemical and Disposable PPE garments for Re-use:-

- Store by hanging rather than folding in cool, dry conditions away from strong light.

- Re-use of chemical safety clothing should ONLY occur when safe to do so.

Disposal of Chemical and Disposable PPE garments:-

- Uncontaminated garments can be disposed of by normal methods such as landfill or incineration according to local regulations.

- Contaminated garment disposal will be subject to the requirements dictated by the chemical and its toxicity or harmfulness.