When it comes to PPE, especially chemical protective clothing, one dangerous truth remains: most people don’t read the standards.

ISO, EN, NFPA, ASTM. All these standards exist to ensure PPE offers at least minimum performance for protecting workers from serious injury or even death. But in too many cases, safety managers and PPE specifiers rely on assumptions or quick-reference data without ever opening the document itself.

Reading the full standard can be an eye-opening experience. And nowhere is this more relevant than in the selection of chemical protective suits.

The Problem with Permeation Resistance

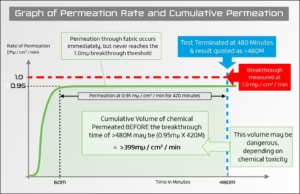

Take the EN 14325 standard, which outlines test methods and classification tables for chemical protective clothing. Within it is the EN 6529 permeation resistance test. This test measures how long a chemical takes to permeate through a fabric and assigns a “normalized breakthrough time” (NBT) in minutes.

This is where the misunderstanding begins. Across the world, specifiers use NBT as a measure of safe-wear time. But that’s exactly what the standard warns against.

Note 1: “It can be dangerous to base considerations of safe wear time… only on the value of normalized breakthrough time for a specific tested chemical.”

In other words, NBT doesn’t tell you when permeation starts, only when the rate of permeation reaches a specific threshold (1.0 μg/cm²·min). A chemical could be seeping through for hours before that point.

Note 2: “For example… a material can be rated class 6 for this chemical… but the cumulative permeated mass… will be slightly below 480 μg/cm². This level of permeation can be dangerous depending on the toxicity of the chemical.”

If you’re working with a highly toxic substance, this slow but steady exposure could be harmful, perhaps even deadly, especially during prolonged or repeated wear.

What the Standard Actually Recommends

Note 3: “Chemical protective clothing materials should… be evaluated with respect to cumulative permeation… to which the skin can be exposed with regard to the skin/dermal toxicity of the tested chemical.”

This is a game-changing insight. The right way to assess a chemical suit is not by NBT alone, but by looking at total permeated volume over time, and matching that against the chemical’s toxicity. Yet despite the standard’s clarity, this message is often missed, simply because the standards aren’t read.

ASTM Has the Same Warning

The issue isn’t limited to EN standards. The ASTM F739 test used in North America follows the same format and includes similar cautions against using NBT to determine protection levels. Science is the same. The risks are the same.

Why This Still Happens

Let’s face it, PPE standards are dense, technical, and time-consuming to read. Many are written in complex languages and require effort to interpret. So, it’s understandable why so many skip them or rely solely on summary data sheets.

But doing so can lead to dangerous misunderstandings, especially when lives are on the line.

Lakeland’s Approach

At Lakeland, we’re committed to helping safety managers make informed, confident decisions. That’s why we developed PermaSURE®, the world’s first app that calculates safe-wear times for Lakeland chemical suits. Based not just on NBT, but cumulative permeation, toxicity, and real-world use conditions.

With access to over 2,000 chemicals and integrated modeling for permeation and inward leakage, PermaSURE®, gives you data-driven guidance when it matters most.

Final Takeaway

Read the standards. You’ll be surprised what they say and what many in the industry continue to overlook. Don’t assume your workers are protected. Make sure of it.

Contact the Lakeland team to learn more about safe chemical suit selection and explore how PermaSURE® can help you model real safety in real time.