This is why proper cleanroom gowning processes are so important. Learning the proper donning and doffing procedures for your disposable cleanroom garments will safeguard your cleanroom or controlled environment against contamination.

Understanding the Cleanroom Gowning Process

The cleanroom gowning process really starts at home. Cleanroom operators must come to work clean, this means:

- Showered

- Shaved

- Teeth brushed

- Minimal skin moisturizers (non-silicone)

- No perfume, after shave, makeup

Controlling for these potential excursion factors sets up your controlled environment for success. In addition to proper hygiene before employees arrive at work, there are specific gowning protocols and procedures that must be followed.

The information provided in this article on cleanroom gowning requirements is intended for informational purposes only. Individual site protocols and procedures should be followed at all times.

Aseptic Gowning Donning Guide

Proper aseptic cleanroom gowning is essential. Read the steps below and view or download a free PDF Aseptic Gowning / Donning Guide with pictures.

- Good Hygiene should be maintained prior to coming to work.

- Remove all jewelry and personal items.

Follow these steps for proper aseptic cleanroom gowning:

- Don bouffant cap, be sure all hair is contained and ears are covered.

- Don disposable shoe covers making sure entire surface of street shoe is contained.

- Wash or sanitize hands. Make sure they dry completely.

- Don first pair of sterile gloves without touching outside surface area of glove.

- Sanitize gloves – this should be done after each step in the gowning process.

- Don Hood – use ties to ensure proper fit.

- Don Mask – adjust for proper fit (no gaps).

- Don Coverall with approved aseptic technique. Touch only the inside of the coverall, do not let coverall touch operator, floor or any surface.

- Don first boot cover with approved aseptic technique, then place first donned boot onto “clean side” of gowning area. Repeat.

- Don Goggles – adjust for sealed fit.

- Second Pair of Sterile Gloves, completely covering the first pair.

- Do final check in mirror prior to entering sterile cleanroom.

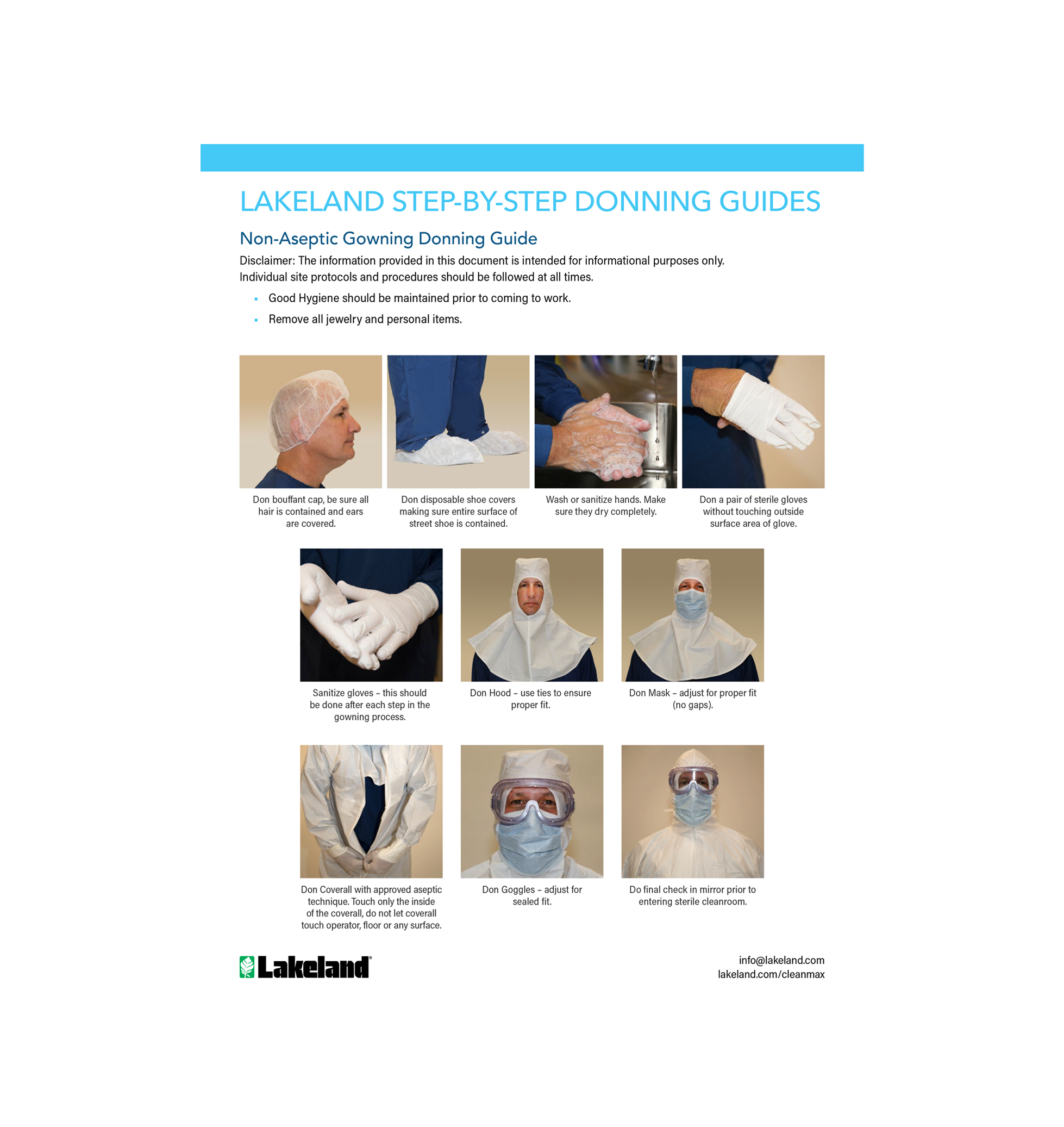

Non-Aseptic Gowning Donning Guide

Looking for step-by-step guidance and pictures on non-aseptic cleanroom gowning? Read the steps below and download a free PDF Non-Aseptic Gowning / Donning Guide with pictures.

- Good hygiene should be maintained prior to coming to work.

- Remove all jewelry and personal items.

Follow these steps for proper non-aseptic cleanroom gowning:

- Don bouffant cap, be sure all hair is contained and ears are covered.

- Don disposable shoe covers making sure entire surface of street shoe is contained.

- Wash or sanitize hands. Make sure they dry completely.

- Don a pair of sterile gloves without touching outside surface area of glove.

- Sanitize gloves – this should be done after each step in the gowning process.

- Don Hood – use ties to ensure proper fit.

- Don Mask – adjust for proper fit (no gaps).

- Don Coverall with approved aseptic technique. Touch only the inside of the coverall, do not let coverall touch operator, floor or any surface.

- Don Goggles – adjust for sealed fit.

- Do final check in mirror prior to entering sterile cleanroom.

Confidence in your cleanroom and/or controlled environment starts with understanding how to select the right disposable apparel for your unique needs. Whether you are in high-tech manufacturing, biotechnology, pharmaceutical manufacturing or compounding, food industry, or medical device manufacturing, proper cleanroom gowning procedure is essential to your success.