High visibility clothing can be cleaned by standards given on the inside of the garment tag. A general rule for proper washing includes no harsh chemicals, regulated wash with liquid detergent, and low tumble dry.

High visibility clothing describes protective garments used in settings where lack of visibility may be hazardous due to lighting conditions, moving vehicles and/or machinery, or plant processes. Depending on the application, you might need high visibility shirts, vests, outerwear, pants, or bib overalls – or a combination of garments.

HVSA risk assessments are created to obtain information for certain tasks that may require specific apparel. The assessment includes factors such as:

Design requirements are outlined to meet set standards for safety apparel and accessories. In adherence to ANSI standards, high visibility clothing is usually made using fluorescent yellow or orange fabric and reflective tape. Employers should select the reflective color and stripe combination suitable for providing preferred visual contrast for the proper HSVA class compliance.

Standards for high visibility clothing are set by the following bodies and standards:

ANSI 107-2020 is the standard set by the American National Standards Institute that defines the working conditions that require high visibility clothing with certain performance requirements, including “color, retroreflection, the recommended configuration, and more. According to ANSI standards, high visibility clothing can be classified in four ways:

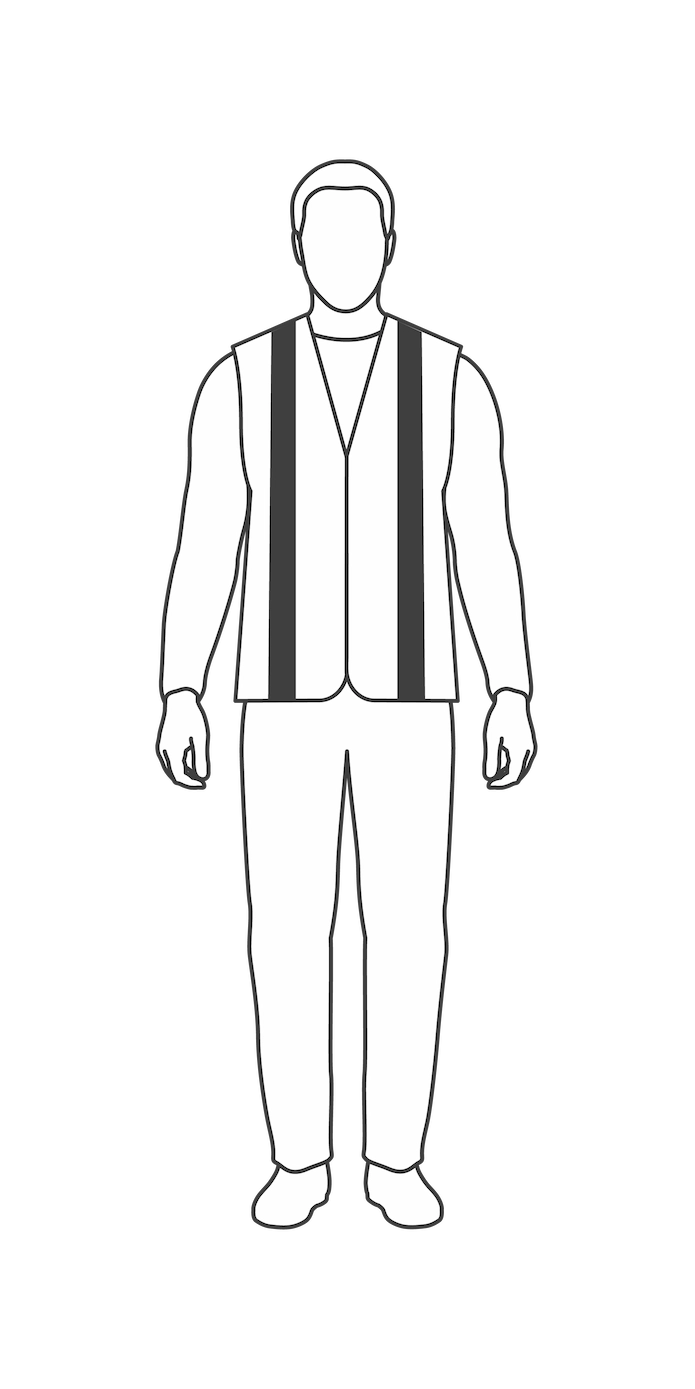

Performance Class 1 offers the lowest level of protection and minimum amounts of high visibility elements. This classification is appropriate for use in Type O environments. These garments must have retroreflective materials on the shoulders or encircling the arms and one horizontal band across the torso.

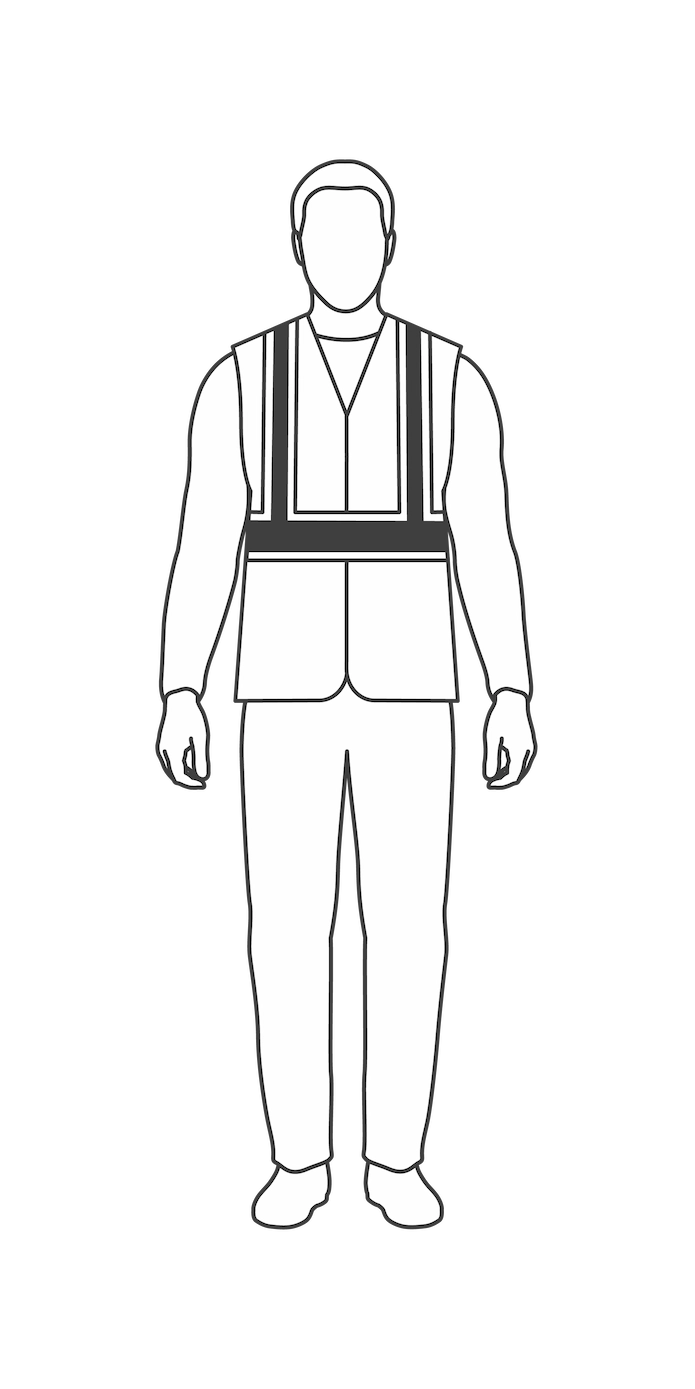

Performance Class 2 includes higher levels of high visibility elements than Performance Class 1 and is appropriate for use in Type R environments. These garments must have at least one horizontal band of retroreflective around the torso and a combined-performance material in the should or encircling the sleeves.

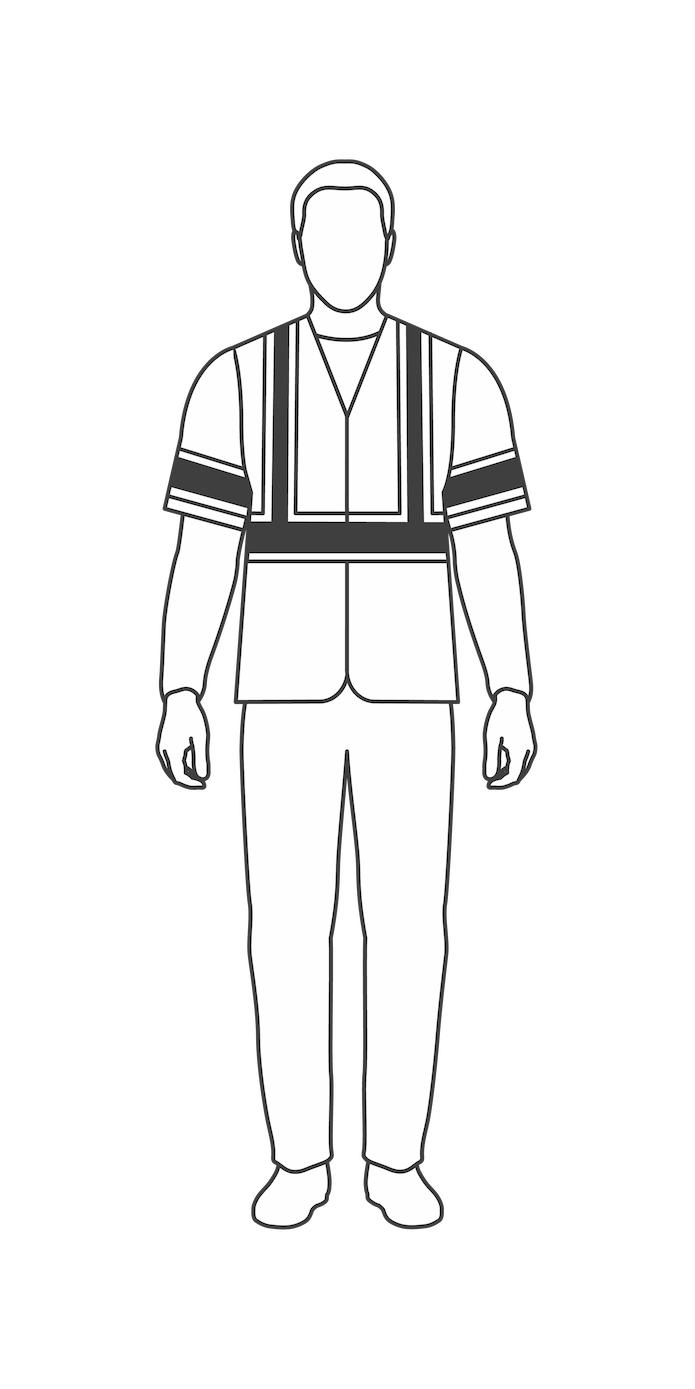

Performance Class 3 garments are made with a higher amount of high visibility materials to be used in extremely complex work environments where an individual’s entire body requires elevated visibility. These garments must include at least one horizontal retroreflective tape around the torso and one or more encircling bands on the sleeves.

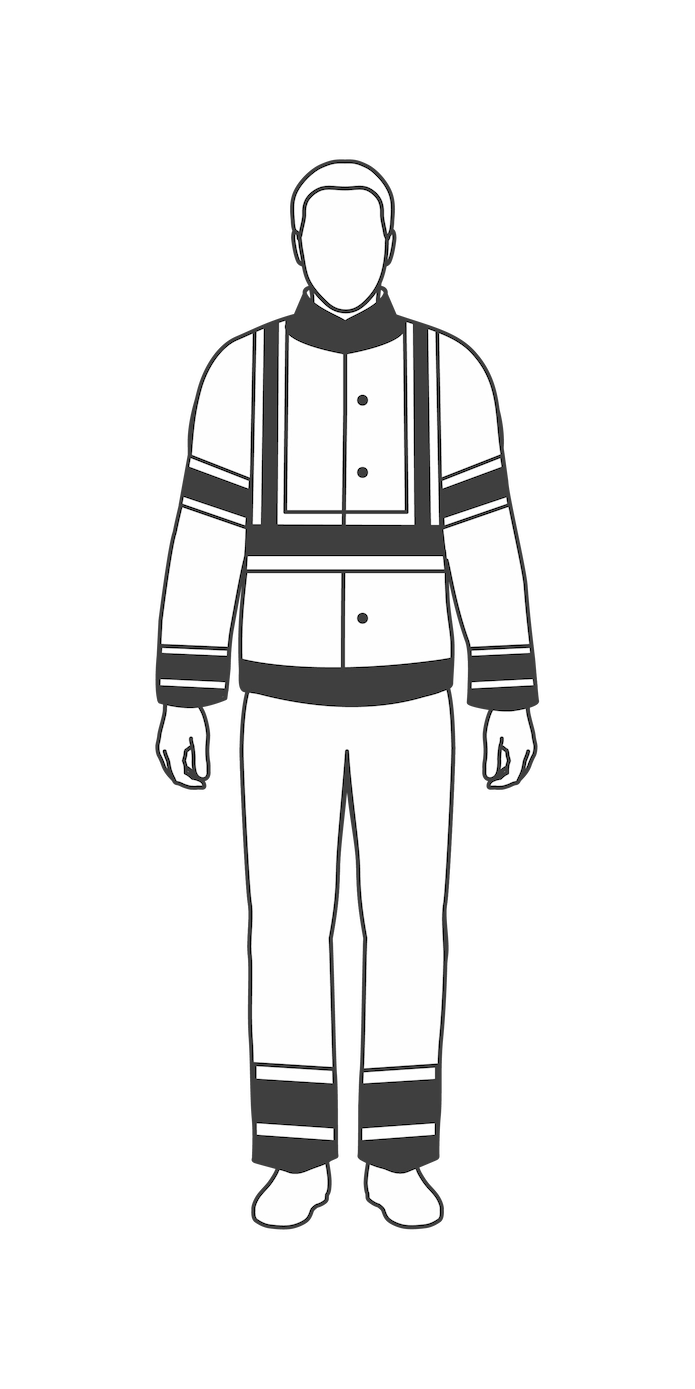

Supplemental Class E is used as support in situations that require high visibility clothing but should never be worn alone, as it does not meet safety standards without the presence of other high visibility garments. These garments should be paired with either Performance Class 2 or Performance Class 3 to create an overall classification of Class 3 protection.

ANSI Standards also identify three types of high visibility clothing:

Type O (off-road): Type O high visibility clothing provides visual enhancement for workers during daytime and nighttime conditions in environments where there is risk for struck-by hazards, such as moving vehicles or machinery. However, this does not include environments with roadway traffic. Examples include parking attendants, refinery and mine workers, oil and gas extraction platform personnel

Type R (roadway): Type R high visibility clothing differs from Type O in that it is intended to provide visual enhancement for workers who are exposed to traffic from public access highways and/or construction zones during daytime and nighttime conditions. Examples include utility personnel, survey and roadway construction crews, airport ground crew

Type P (public safety): Type P high visibility clothing is intended for use by emergency responders and law enforcement personnel in situations where they are exposed to traffic from public roadways, construction zones, or other moving equipment in daytime or nighttime conditions. Examples include law enforcement agents, firefighters, EMS personnel

OSHA policy speaks to two situations when high visibility clothing is required for workers. Specifically, when they are working as flaggers or when they are exposed to “public vehicular traffic in the vicinity of excavations.”

ISO 20471 is an international standard that details the requirements and testing methods necessary to manufacture high visibility clothing in terms of material durability and capacity to increase wearer visibility. For high visibility clothing to comply with ISO 20471, manufacturers must meet standards for:

High visibility clothing is critical for protecting your people in low-light conditions. It should comply with ANSI standards for color and reflective tape placement without contributing to worker discomfort. PPE such as vests are commonly worn over some workwear; however, you can find a variety of high visibility shirts, disposable coveralls, and outerwear below.

High visibility clothing can be cleaned by standards given on the inside of the garment tag. A general rule for proper washing includes no harsh chemicals, regulated wash with liquid detergent, and low tumble dry.

High visibility clothing can be classified in four ways by ANSI standards:

High visibility clothing describes protective garments used in settings where lack of visibility may be hazardous due to lighting conditions, moving vehicles and/or machinery, or plant processes.

High visibility clothing is usually worn in low light and dark conditions to increase the safety of your workers through the contrast between clothing and the work environment.