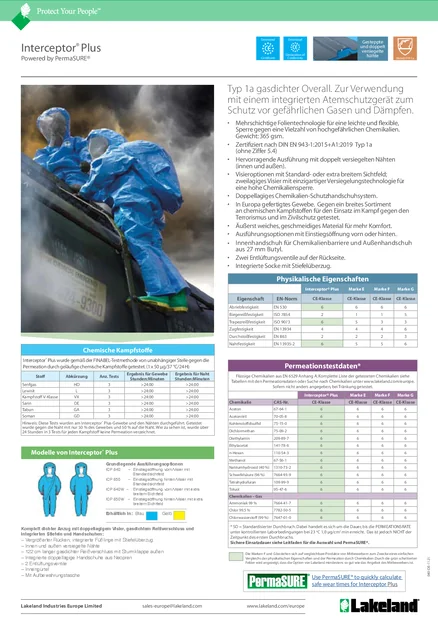

Interceptor® Plus

Interceptor Plus is the top level protection in Lakeland® Chemical Protective Clothing.

Available in both Level A encapsulating and non-encapsulating configurations there is an Interceptor Plus style for your needs – be it gas, vapor, aerosol, liquids, harmful contaminants or particulate protection.

Products

Filter by Garment Type

More

Filter by Seam Type

More

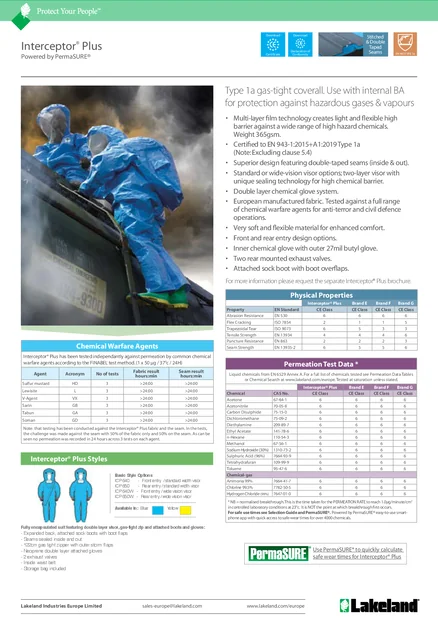

Interceptor® Plus Chemical Test Data

| Chemical Tested | CAS Number | Phase | Concentration | ASTM F739 | EN 6529 | ISO Class | |

|---|---|---|---|---|---|---|---|

| 1,3-BUTADIENE GAS | 106-99-0 | LIQUID | 99% | >480 | >480 | 6 | |

| 2,2,2-TRICHLOROETHANOL | 115-20-8 | LIQUID | 99% | >480 | >480 | 6 | |

| 2,3 DICHLORO- 1PROPENE | 78-88-6 | LIQUID | 98% | >480 | >480 | 6 | |

| 2,4-DICHLOROPHENOL | 120-83-2 | LIQUID | 99% | >480 | >480 | 6 | |

| 2,4-DICHLOROPHENOXY ACETIC ACID | 94-75-7 | LIQUID | 99% | >480 | >480 | 6 | |

| 4-BROMOFLUOROBENZENE | 460-00-4 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETIC ACID | 64-19-7 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETONE | 67-64-1 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETONITRILE | 75-05-8 | LIQUID | 99% | >480 | >480 | 6 | |

| ACETYL CHLORIDE | 75-36-5 | LIQUID | 98% | >480 | >480 | 6 | |

| ACROLEIN | 0107-02-08 | LIQUID | 98% | >480 | >480 | 6 | |

| ACRYLIC ACID | 79-10-7 | LIQUID | 99% | >480 | >480 | 6 | |

| ACRYLONITRILE | 107-13-1 | LIQUID | 99% | >480 | >480 | 6 | |

| ALLYL CHLORIDE | 0107-05-01 | LIQUID | 99% | >480 | >480 | 6 | |

| AMMONIA | 7664-41-7 | GAS | 99% | >480 | >480 | 6 | |

| AMMONIUM FLUORIDE | 12125-01-08 | LIQUID | 40% | >480 | >480 | 6 | |

| BROMINE | 7726-95-6 | LIQUID | >99% | 98 | 102 | 3 | |

| CARBON DISULFIDE | 75-15-0 | LIQUID | 99% | >480 | >480 | 6 | |

| CARBON TETRACHLORIDE | 56-23-5 | LIQUID | 99% | >480 | >480 | 6 | |

| CHLORINE | 7782-50-5 | GAS | 99% | >480 | >480 | 6 | |

| o-Cresol | 95-48-7 | LIQUID | 99% | >480 | >480 | 6 | |

| DICHLOROMETHANE | 75-09-2 | LIQUID | 99% | >480 | >480 | 6 | |

| DIETHYLAMINE | 109-89-7 | LIQUID | 99% | >480 | >480 | 6 | |

| DIMETHYL FORMAMIDE | 68-12-2 | LIQUID | 99% | >480 | >480 | 6 | |

| EPICHLOROHYDRIN | 106-89-8 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYL ACETATE | 141-78-6 | LIQUID | 99% | >480 | >480 | 6 | |

| ETHYLENE OXIDE | 75-21-8 | GAS | 99% | >480 | >480 | 6 | |

| HEXANE | 110-54-3 | LIQUID | 99% | >480 | >480 | 6 | |

| HYDROFLUORIC ACID | 7664-39-3 | LIQUID | 70% | >480 | >480 | 6 | |

| HYDROGEN CHLORIDE | 7647-01-0 | GAS | 99% | >480 | >480 | 6 | |

| HYDROGEN FLUORIDE | 7664-39-3 | GAS | 99% | >480 | >480 | 6 | |

| METHANOL | 67-56-1 | LIQUID | 99% | >480 | >480 | 6 | |

| METHYL CHLORIDE | 74-87-3 | GAS | 99% | >480 | >480 | 6 | |

| NITROBENZENE | 98-95-3 | LIQUID | 99% | >480 | >480 | 6 | |

| PCB (TRANSFORMER OIL) | PCB | LIQUID | Mixture | >480 | >480 | 6 | |

| PHOSPHOROUS PENTACHLORIDE | 10026-13-8 | LIQUID | 99% | >480 | >480 | 6 | |

| SODIUM HYDROXIDE | 1310-73-2 | LIQUID | 50% | >480 | >480 | 6 | |

| SODIUM HYDROXIDE | 1310-73-2 | LIQUID | SAT. | >480 | >480 | 6 | |

| SULFURIC ACID | 7664-93-9 | LIQUID | 98% | >480 | >480 | 6 | |

| SULPHUR DIOXIDE | 7446-09-05 | GAS | 99% | >480 | >480 | 6 | |

| SULFURYL CHLORIDE | 7791-25-5 | LIQUID | 97% | >480 | >480 | 6 | |

| TETRACHLOROETHYLENE | 127-18-4 | LIQUID | 99% | >480 | >480 | 6 | |

| TETRAHYDROFURAN | 109-99-9 | LIQUID | 99% | >480 | >480 | 6 | |

| THIONYL CHLORIDE | 7719-09-07 | LIQUID | 99% | 90 | 97 | 3 | |

| TOLUENE | 108-88-3 | LIQUID | 99% | >480 | >480 | 6 | |

| TRIMETHYL PHOSPHATE | 512-56-1 | LIQUID | 99% | >480 | >480 | 6 | |

| VINYL CHLORIDE | 75-01-4 | LIQUID | 99% | >480 | >480 | 6 |

Please Note:

All test results quoted are from testing carried out at independent laboratories to the relevant {ASTM/CE} Standard(s). Unless stated otherwise tests are carried out on samples of the relevant protective material as opposed to finished garments. Note that all testing is conducted at specific temperatures according to ASTM or EN standard requirements. As permeation is affected by temperature it is important to consider the likely temperature in any application. Permeation test results record a time to a specific permeation rate as defined by the relevant standard and NOT a time to initial breakthrough of the chemical. Also note that differences may be apparent in some cases between CE and ASTM test results. Whilst the tests are similar, the CE standard records a time to a permeation rate of 1.0µg / min / cm2, whilst ASTM records a time to a permeation rate of 0.10µg / min / cm2. This may explain differences between results. As with all Personal Protective Equipment, selection should be based upon the end users risk assessment, it is the responsibility of the end user to determine the suitability of any PPE as part of this risk assessment and to comply with any/all legislative/governmental requirements. Contact Lakeland for more information.