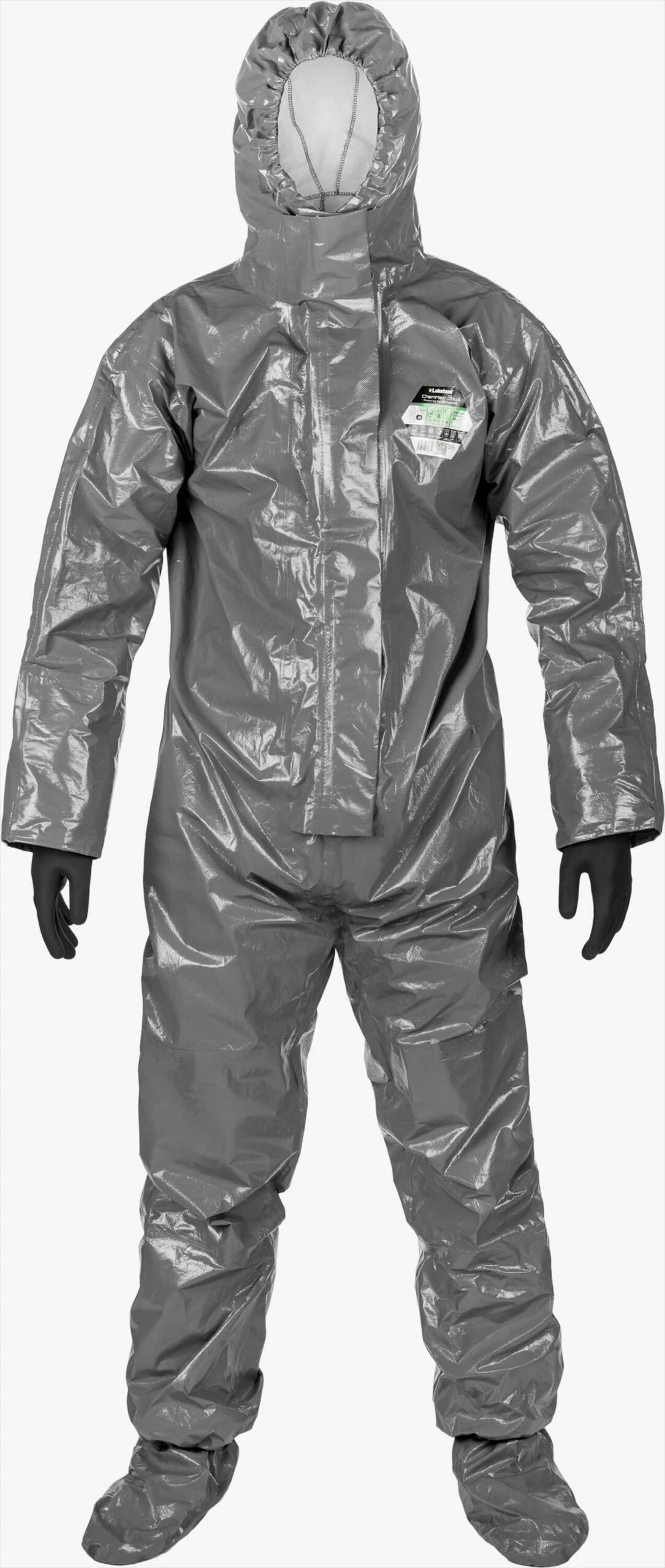

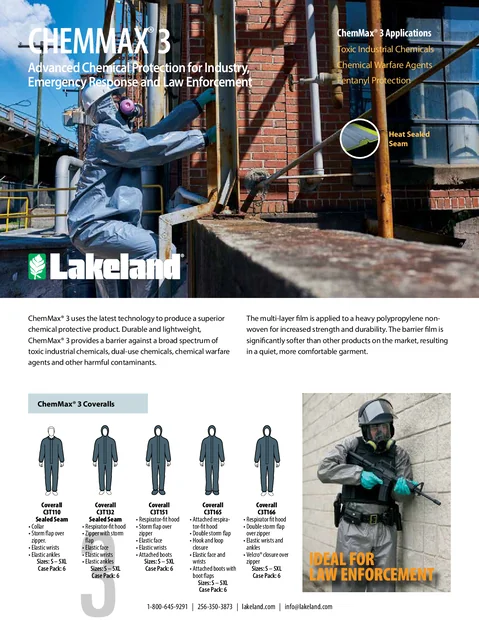

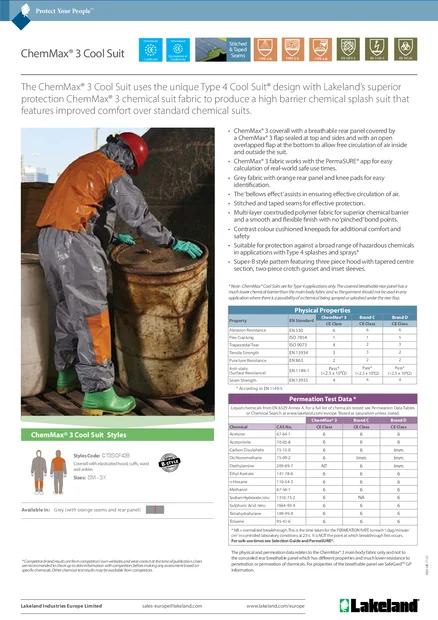

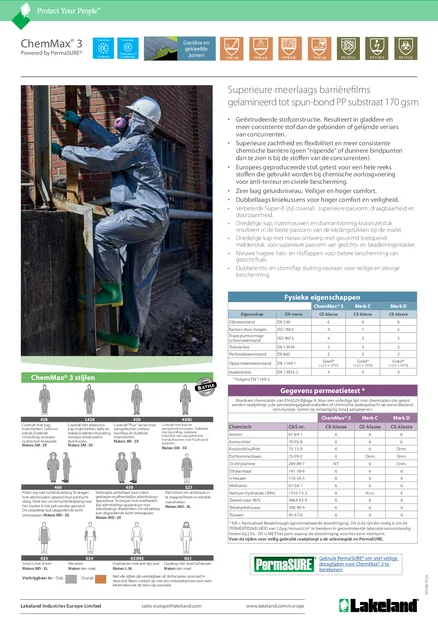

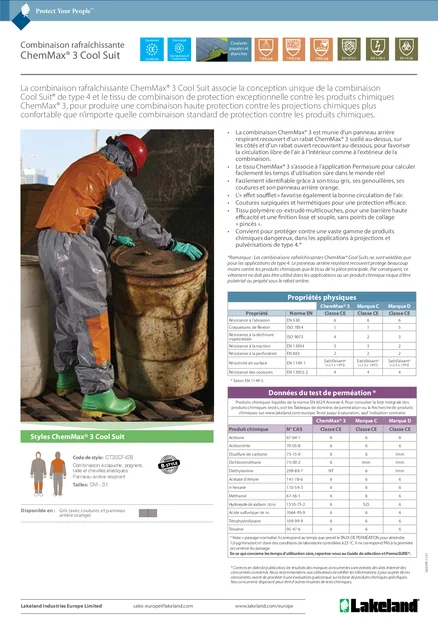

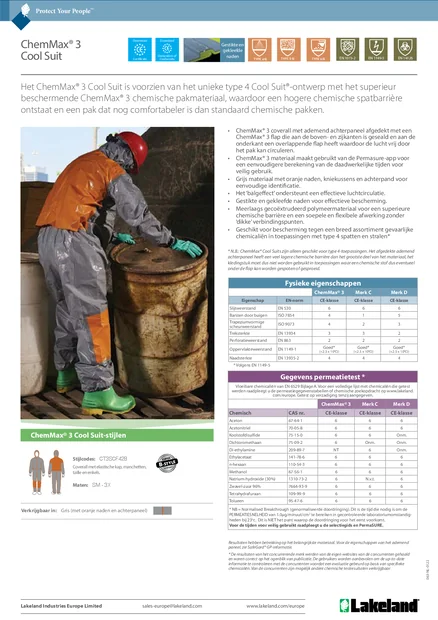

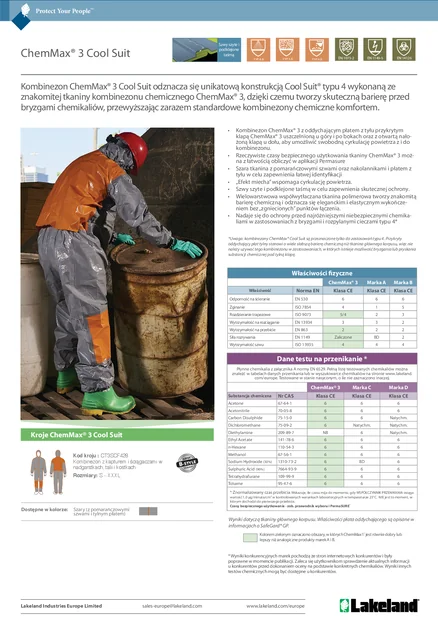

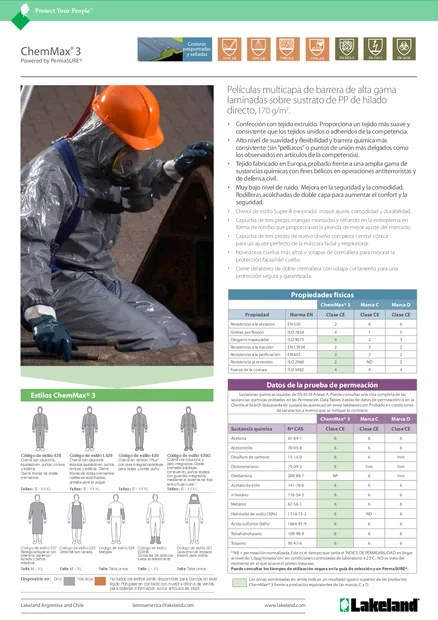

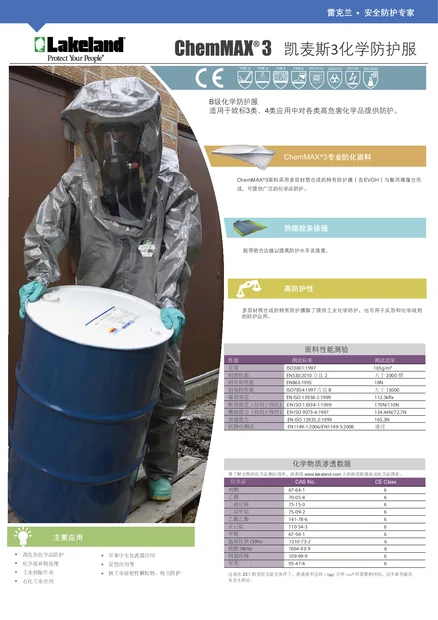

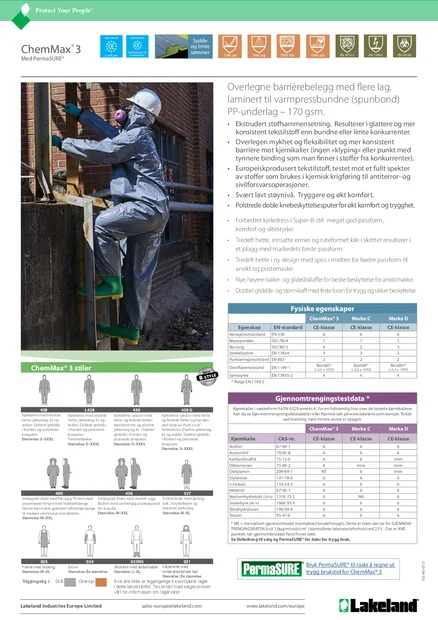

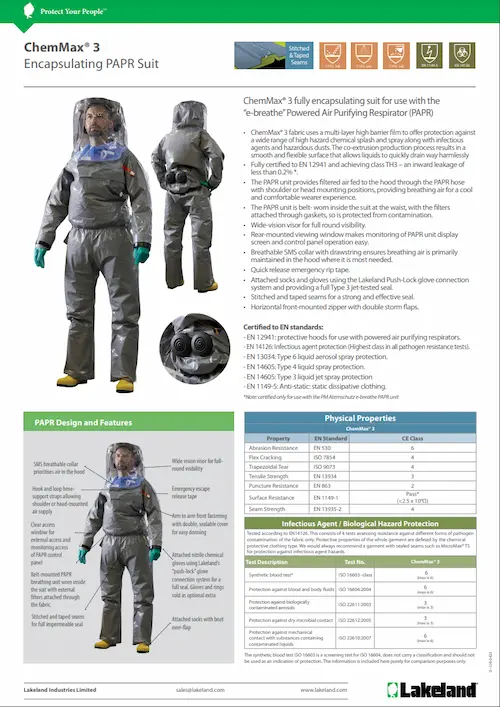

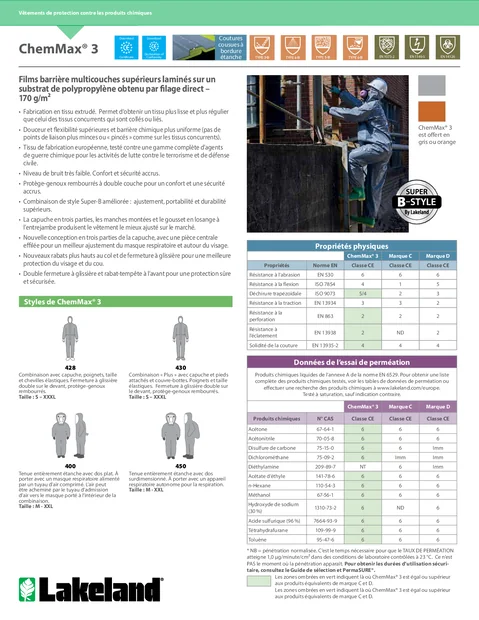

ChemMax® 3 Coverall with Double Zip & Storm Flap, Double Cuffs, Attached Socks with Boot Overflap

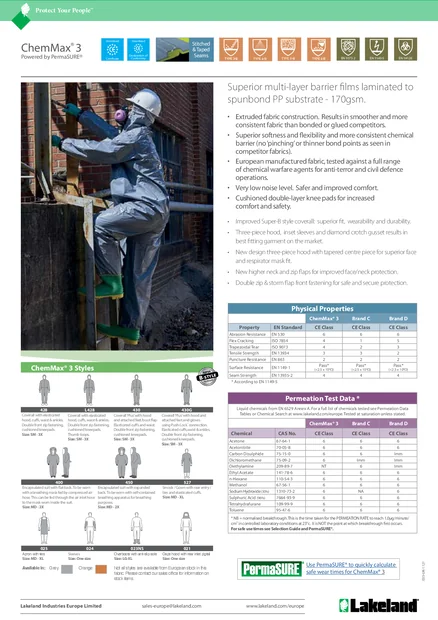

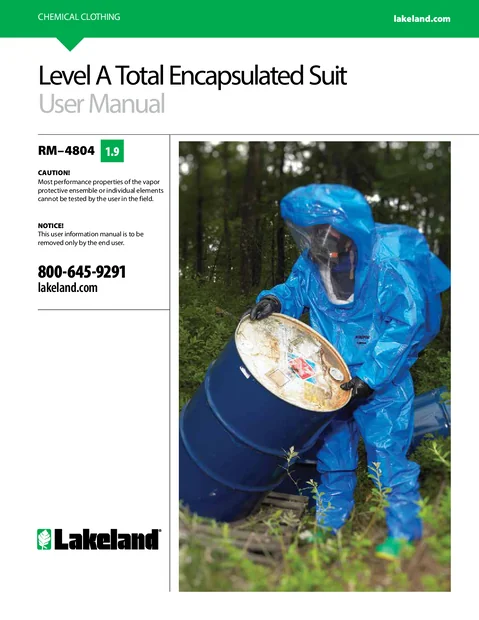

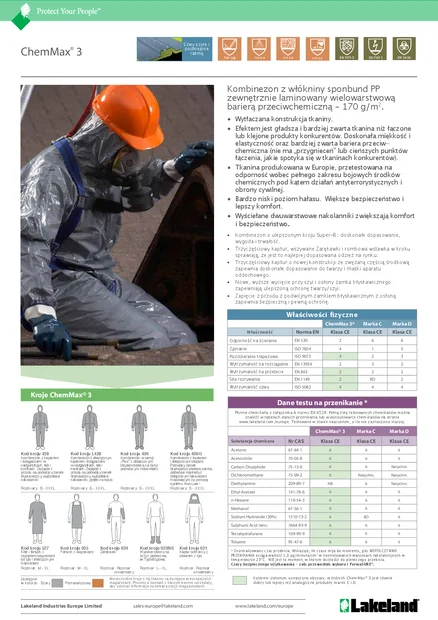

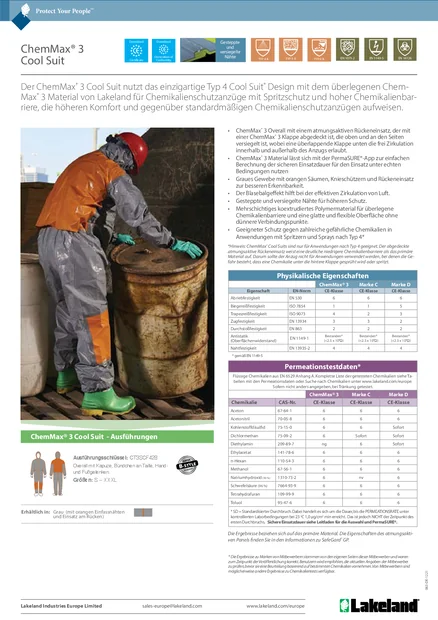

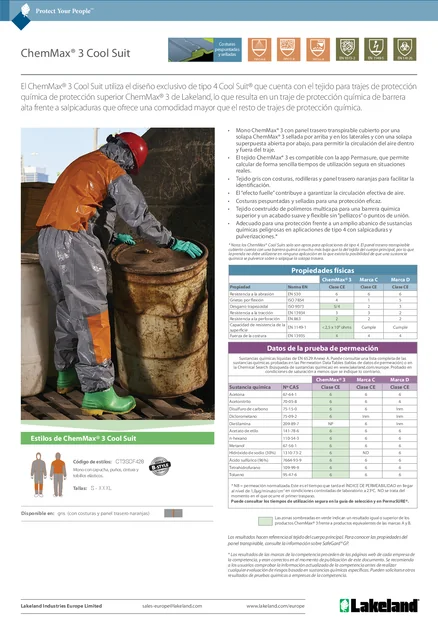

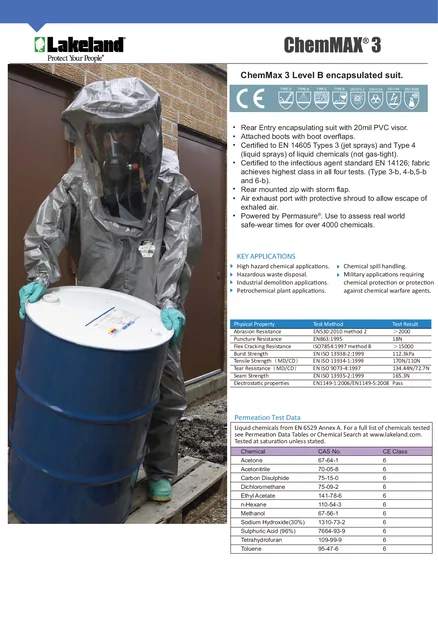

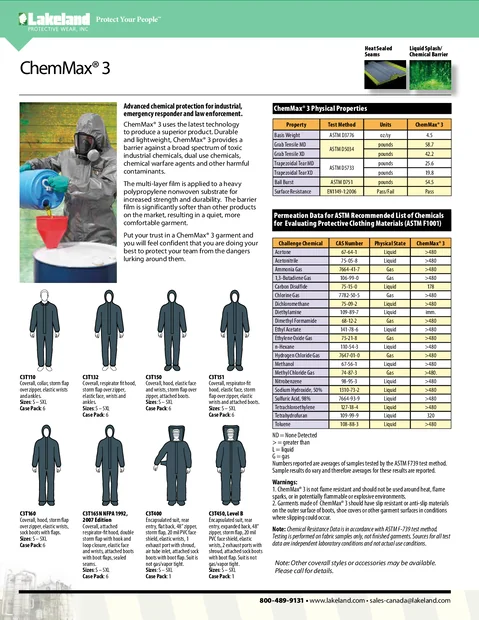

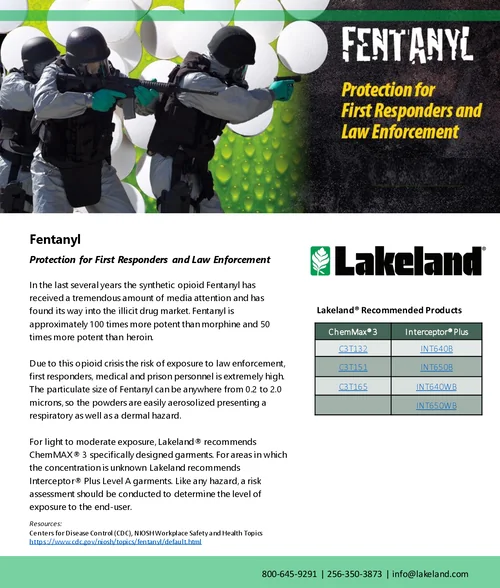

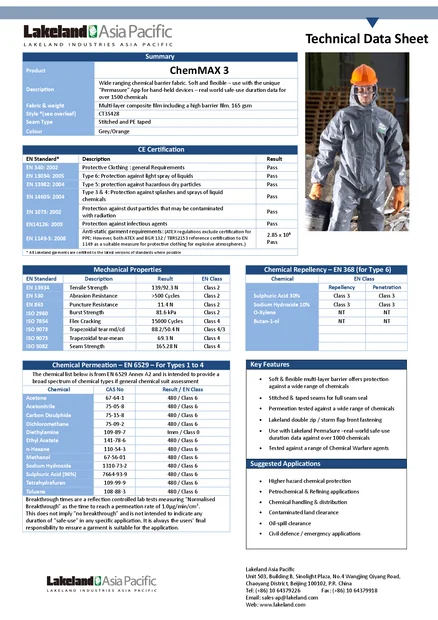

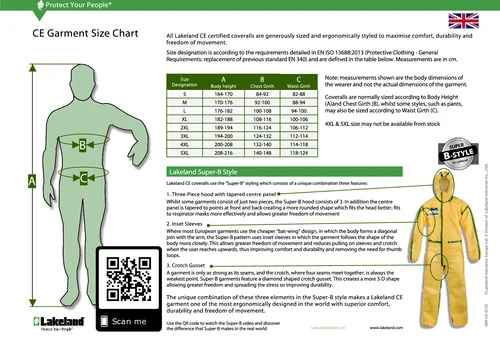

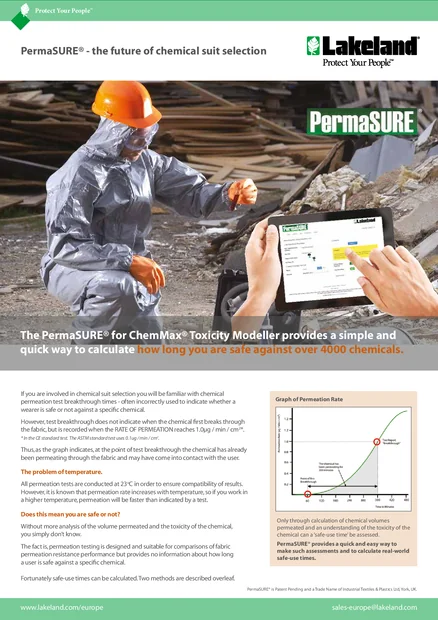

Chemical protective coverall with elastic hood and waist, double cuffs, attached socks with boot overflap and supported by Permasure‚®. EN Type 3 liquid jet spray and Type 4 liquid spray chemical protection. Multi-layer barrier film ChemMax‚® 3 fabric offers high level permeation resistance against many dangerous chemicals. Permeation resistance tested to over 130 chemicals, it also works with Permasure‚®, Lakeland's easy-to-use smart-phone app that calculates safe-wear times for over 4000 chemicals, accounting for the effect of temperature on permeation rate and chemical toxicity. The fabric co-extrusion production process results in a low noise, flexible and smooth finish that is more fabric-like and has no bonding dimples where a chemical might cling as commonly seen in many chemical suit fabrics. Infectious Agent Barrier – passes all four EN 14126 bio-hazard tests at the highest classes. Tested for resistance against seven key chemical warfare agents so suitable for military, anti-terrorist and civil defense applications. Lakeland‘s unique Super-B style featuring 3-piece hood, inset sleeves and crotch gusset for better fit, superior freedom of movement, comfort and durability. Double zip and storm flap front fastening and in-built cushioned knee-pads for added comfort and protection. Certified to EN 1149-5 for static dissipative clothing.Lakeland style number‚ CT3S430G is available with gloves.

Additional information

| Garment Type | Coverall |

|---|---|

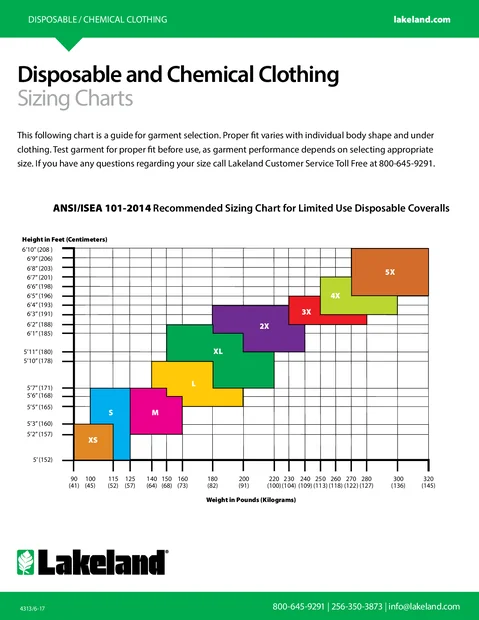

| Sizes | SM – 5X |

| Case Size | 10 |

- Available in these sales regions: Africa Sales Region, Antarctica Sales Region, Asia Sales Region, Central America Sales Region, China Sales Region, Europe Sales Region, India Sales Region, Mexico Sales Region, Middle East Sales Region, Oceania Sales Region, Russia Sales Region, South America Sales Region