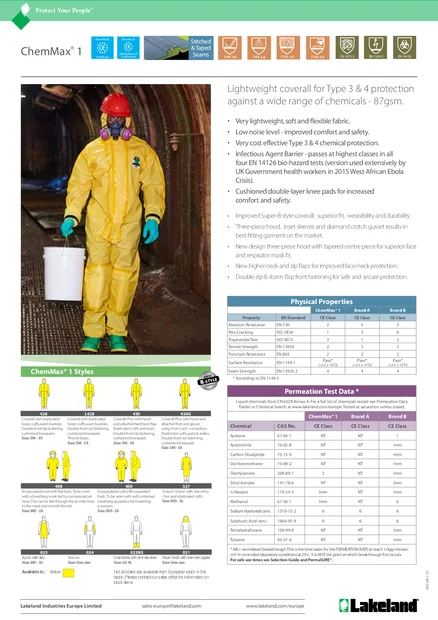

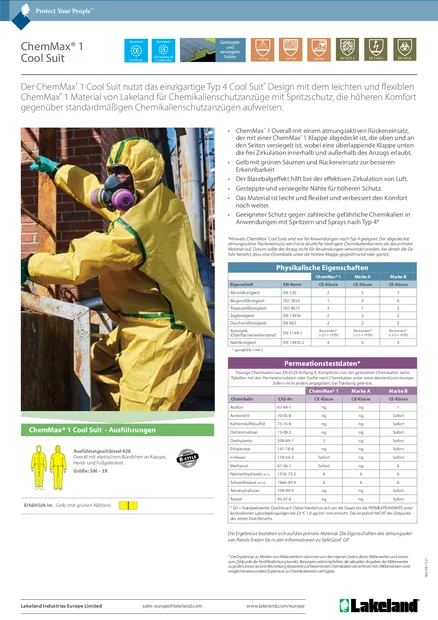

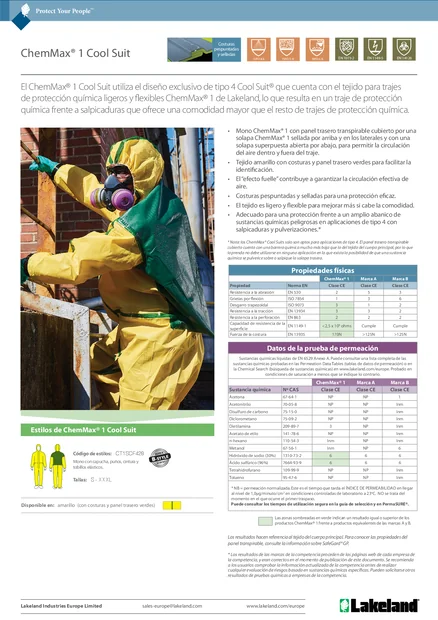

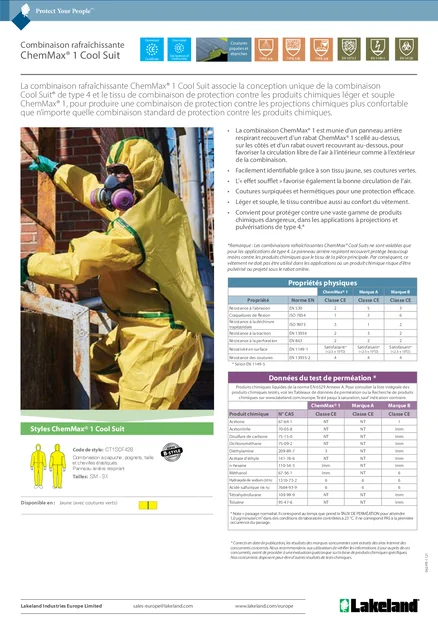

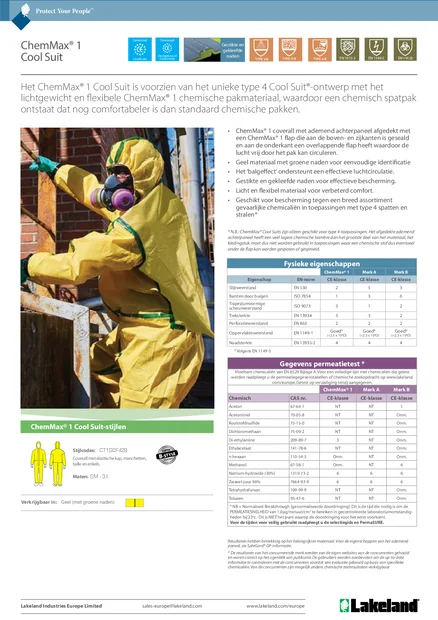

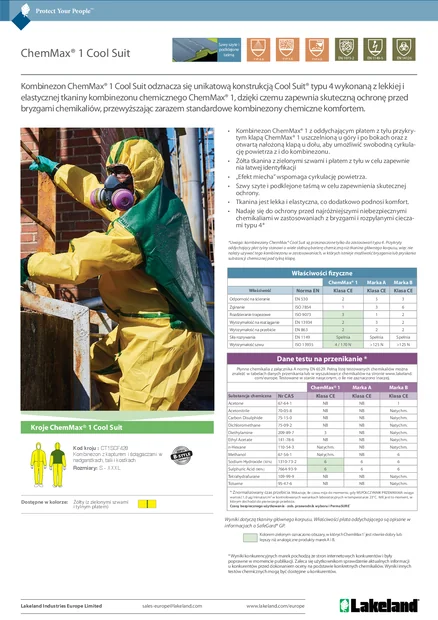

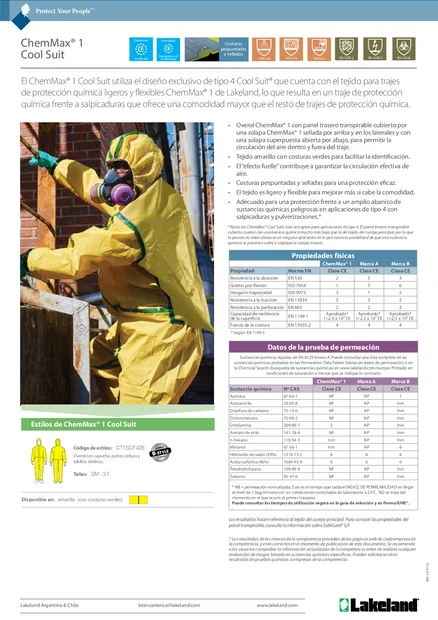

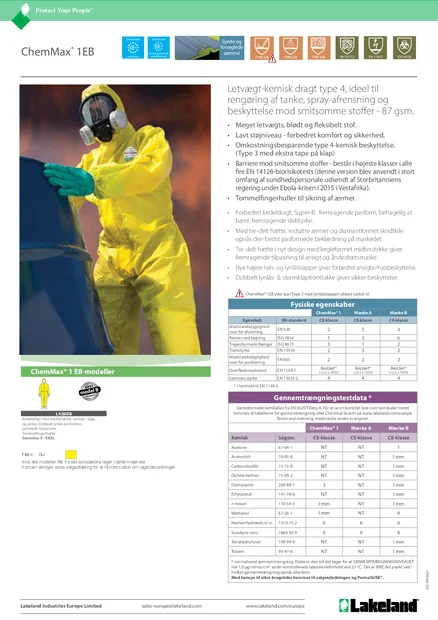

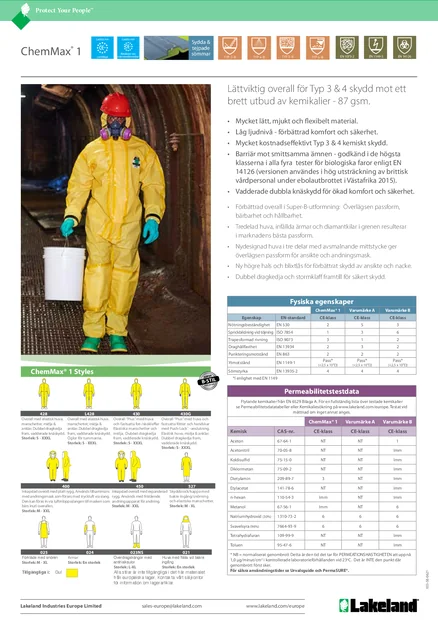

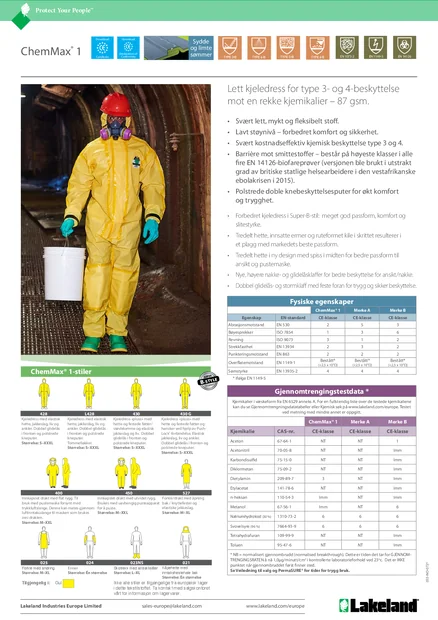

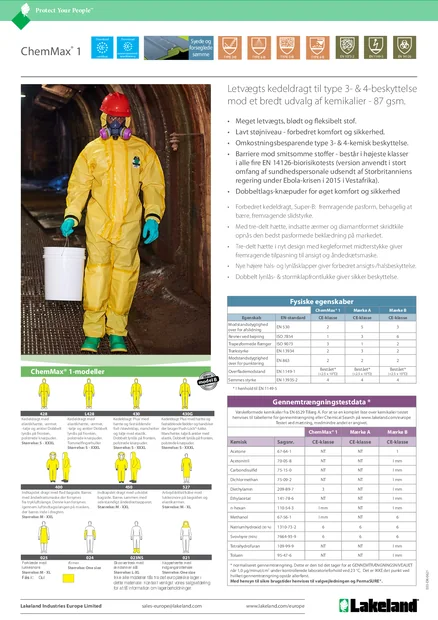

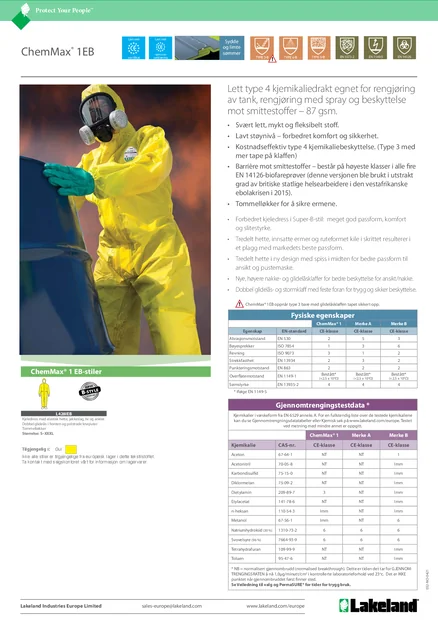

ChemMax® 1 Coverall – Double Zip & Storm Flap and Elastic Hood, Cuffs, Waist and Ankles

Style Number:

CT1S428

Categories: Chemical Suits, ChemMax® 1

If you’re interested in availability, please speak with a Lakeland product specialist or your local distributor.

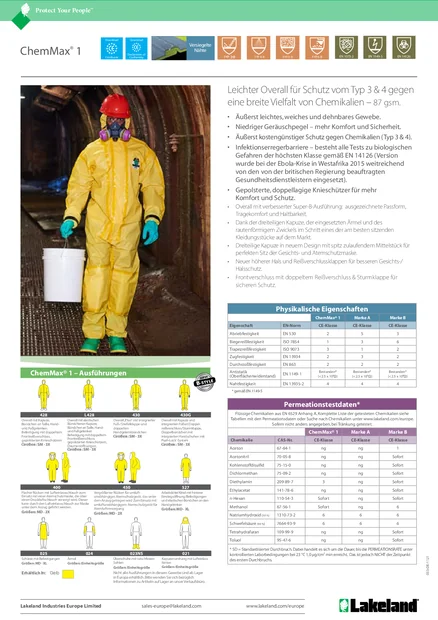

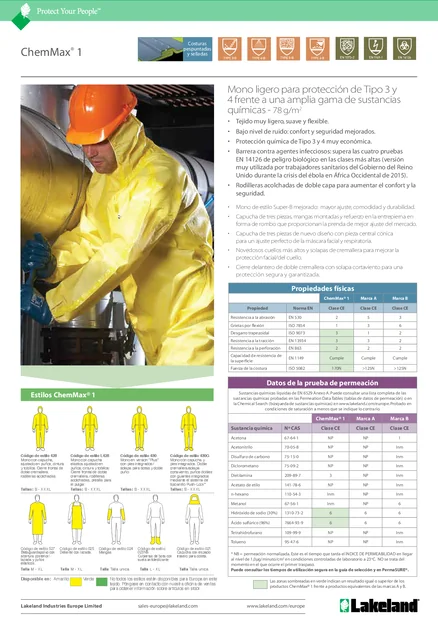

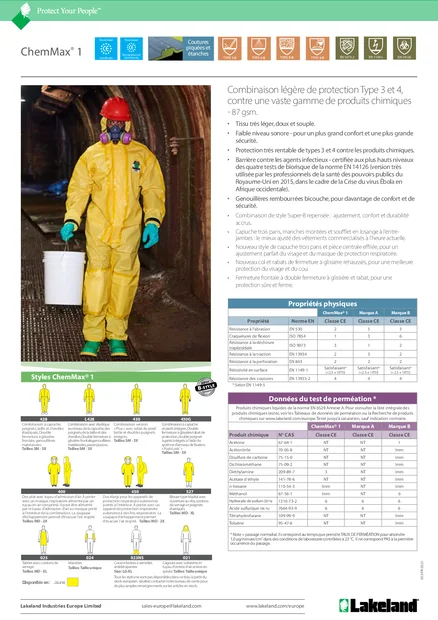

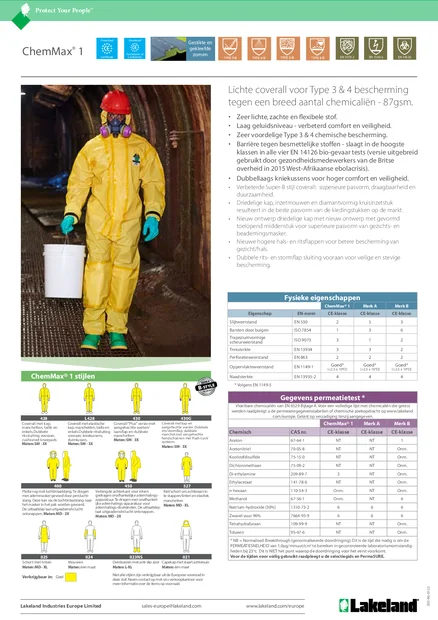

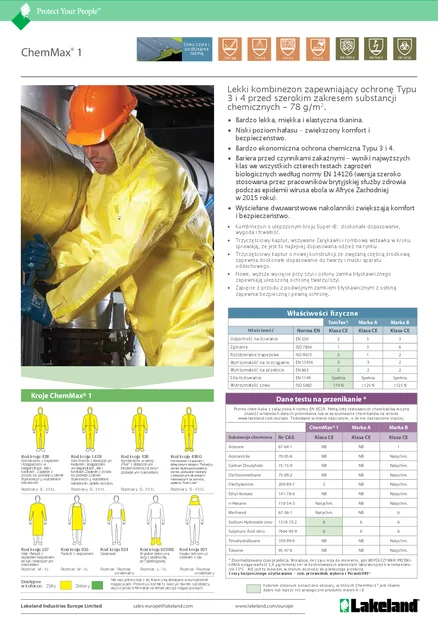

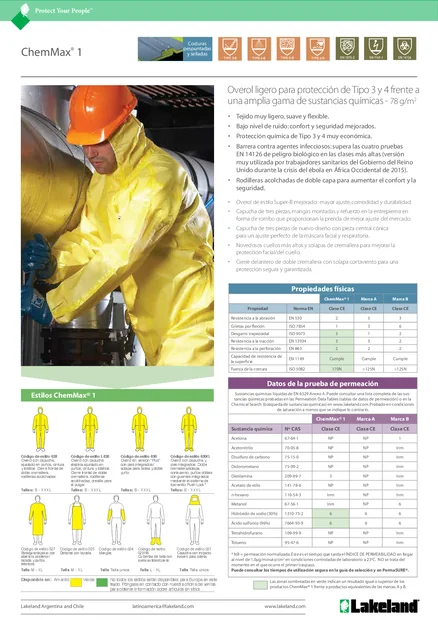

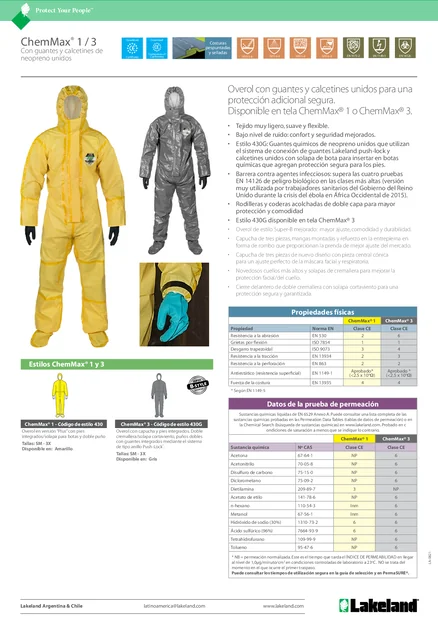

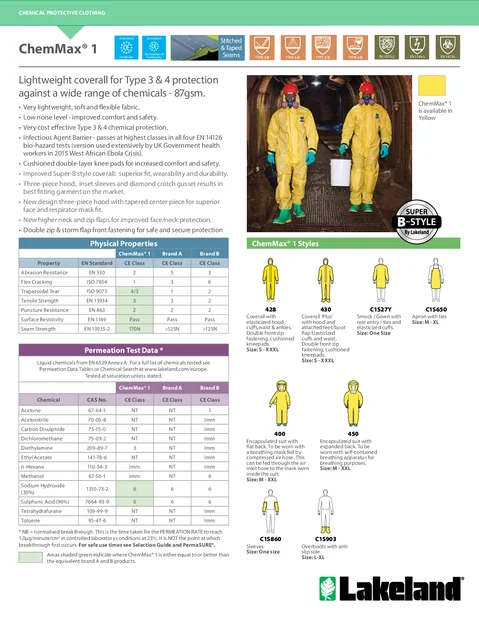

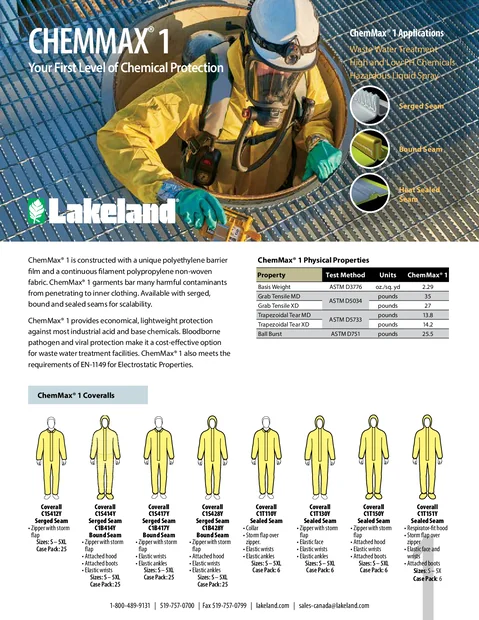

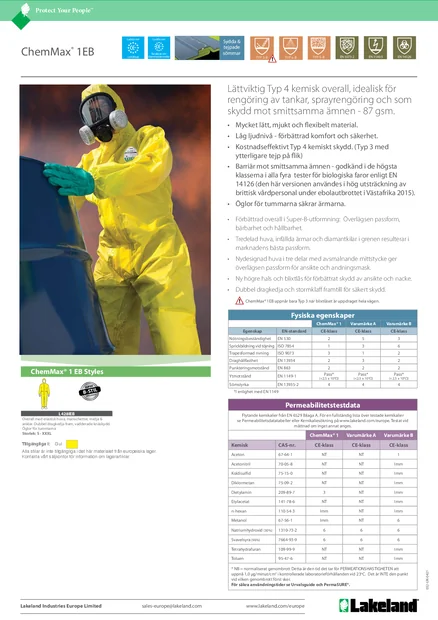

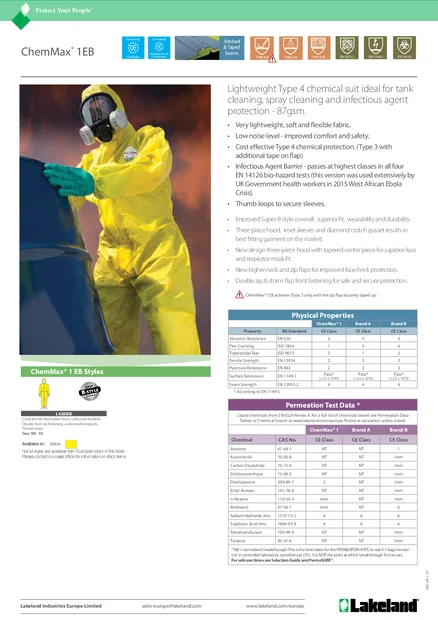

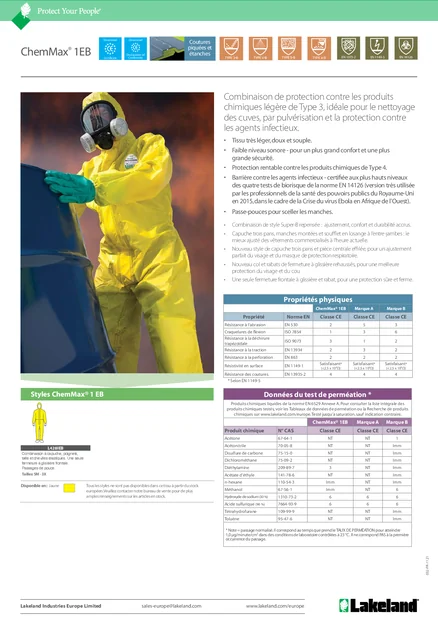

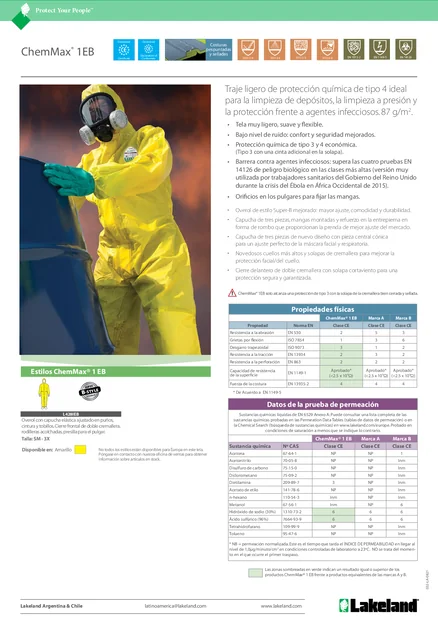

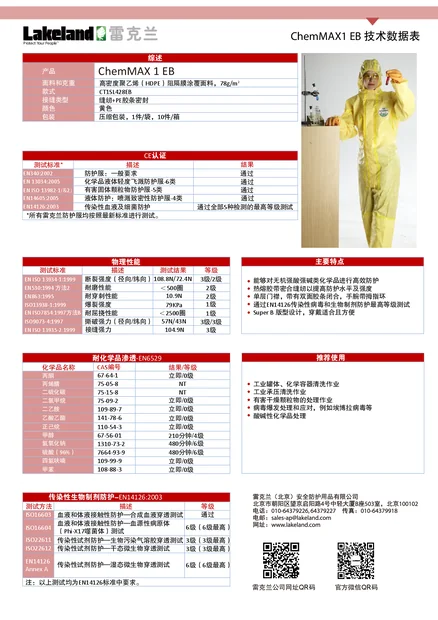

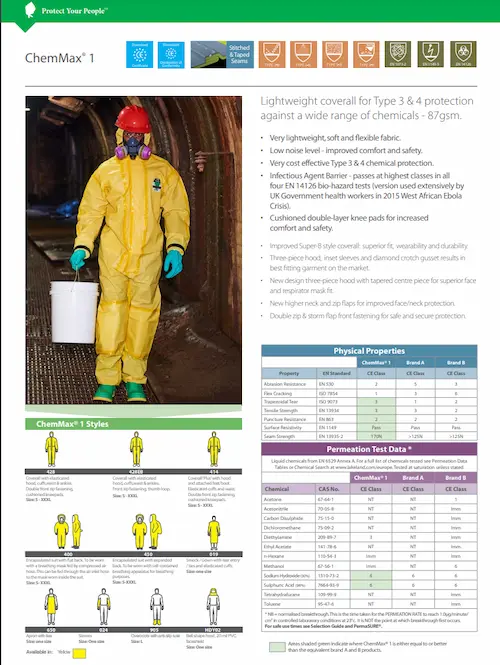

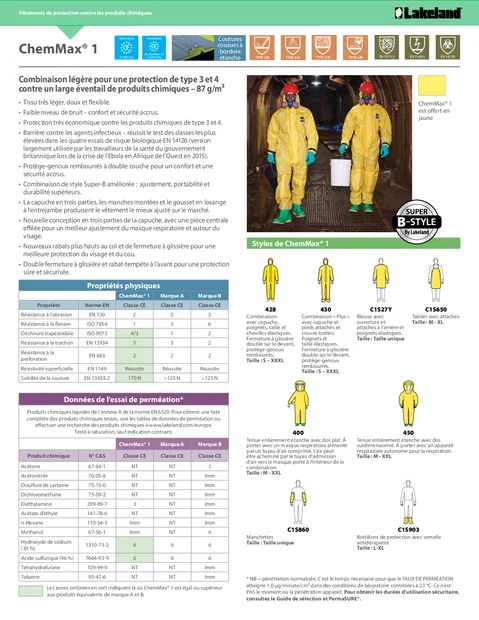

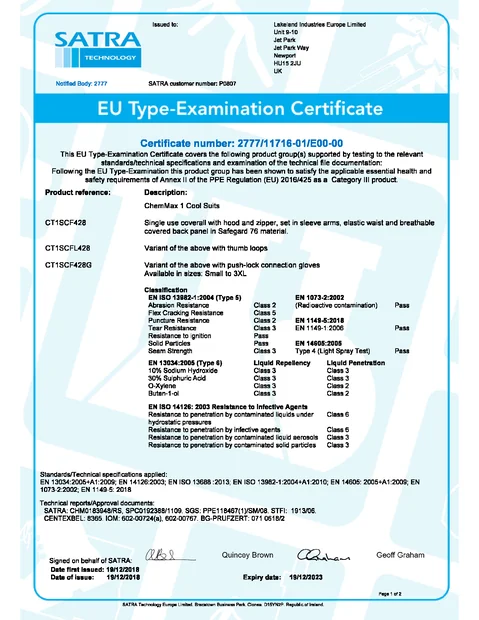

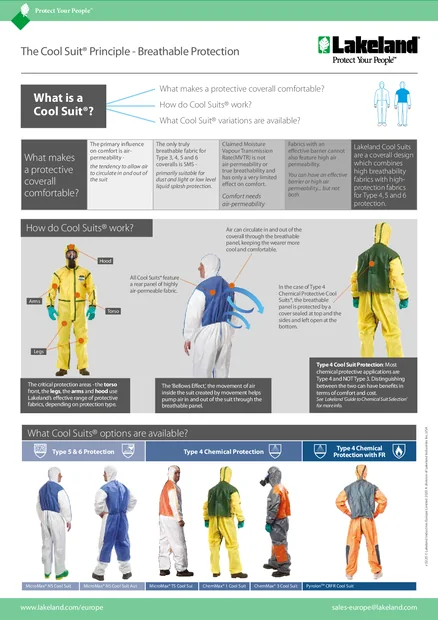

Very light, soft and flexible fabric with stitched and taped seam construction. Low noise level for improved comfort and safety. EN Type 3 liquid jet spray and Type 4 liquid spray chemical protection. Infectious Agent Barrier – passes all four EN 14126 bio-hazard tests at the highest classes. Lakeland‘s unique Super-B style featuring 3-piece hood, inset sleeves and crotch gusset for better fit, superior freedom of movement, comfort and durability. Double zip and storm flap front fastening and in-built cushioned knee-pads for added comfort and protection. Certified to EN1149-5 for static dissipative clothing.

Very light, soft and flexible fabric with stitched and taped seam construction. Low noise level for improved comfort and safety. EN Type 3 liquid jet spray and Type 4 liquid spray chemical protection. Infectious Agent Barrier – passes all four EN 14126 bio-hazard tests at the highest classes. Lakeland‘s unique Super-B style featuring 3-piece hood, inset sleeves and crotch gusset for better fit, superior freedom of movement, comfort and durability. Double zip and storm flap front fastening and in-built cushioned knee-pads for added comfort and protection. Certified to EN1149-5 for static dissipative clothing.

Very light, soft and flexible fabric with stitched and taped seam construction. Low noise level for improved comfort and safety. EN Type 3 liquid jet spray and Type 4 liquid spray chemical protection. Infectious Agent Barrier – passes all four EN 14126 bio-hazard tests at the highest classes. Lakeland‘s unique Super-B style featuring 3-piece hood, inset sleeves and crotch gusset for better fit, superior freedom of movement, comfort and durability. Double zip and storm flap front fastening and in-built cushioned knee-pads for added comfort and protection. Certified to EN1149-5 for static dissipative clothing.

Features: Double flap, Gusseted crotch with 2 diamond-shaped pieces, Elasticated hood, waist, wrists and ankles

Additional information

| Garment Type | Coverall |

|---|---|

| Case Size | 10 |

- Available in these sales regions: Africa Sales Region, Antarctica Sales Region, Asia Sales Region, Canada Sales Region, Central America Sales Region, China Sales Region, Europe Sales Region, India Sales Region, Mexico Sales Region, Middle East Sales Region, Oceania Sales Region, Russia Sales Region, South America Sales Region