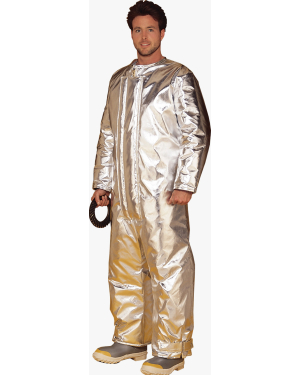

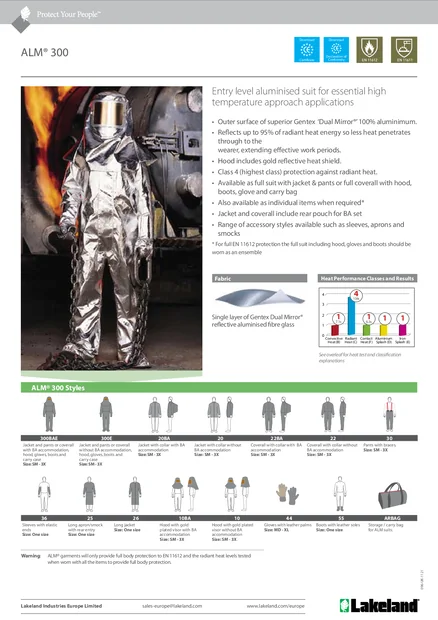

Heat Protective Clothing

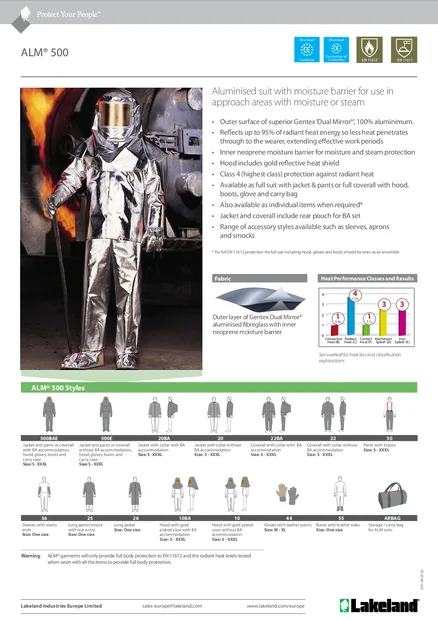

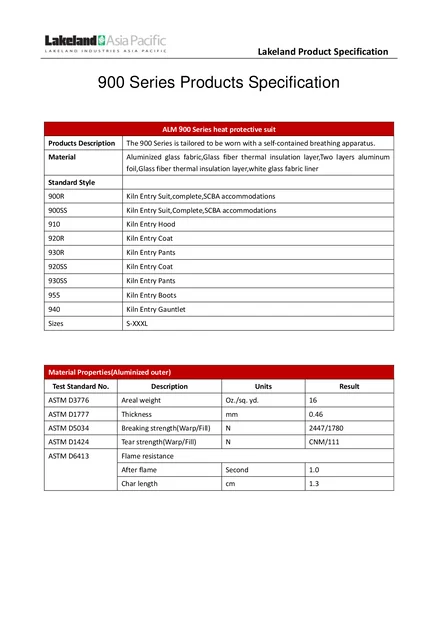

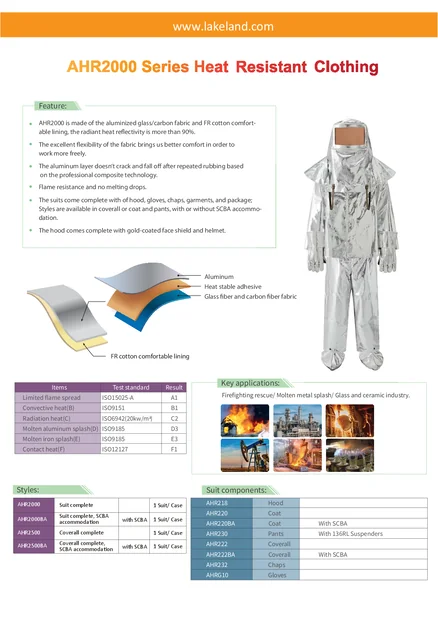

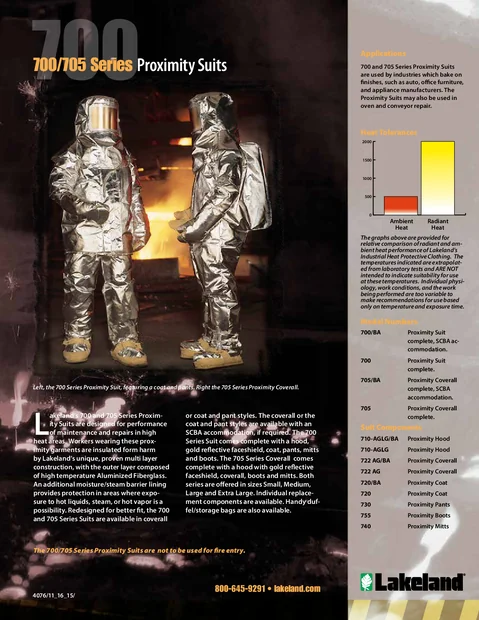

Exposure to radiant heat, molten metals, and flammable substances necessitate the use of robust, high-heat protective clothing to ward off or reduce injury.

Radiant heat, as well as steam and vapor, hold the potential to permeate protective apparel, making the seam construction in heat protective clothing a critical aspect, especially when fabric penetration isn’t the sole risk.

From thermal chemical protection to fully encapsulating aluminized suits, identifying heat energy type and the potential level of heat energy transfer should be the first evaluation in determining the proper heat protection required.

Products

Filter by Garment Type

More

Filter by Seam Type

More

Please Note:

All test results quoted are from testing carried out at independent laboratories to the relevant {ASTM/CE} Standard(s). Unless stated otherwise tests are carried out on samples of the relevant protective material as opposed to finished garments. Note that all testing is conducted at specific temperatures according to ASTM or EN standard requirements. As permeation is affected by temperature it is important to consider the likely temperature in any application. Permeation test results record a time to a specific permeation rate as defined by the relevant standard and NOT a time to initial breakthrough of the chemical. Also note that differences may be apparent in some cases between CE and ASTM test results. Whilst the tests are similar, the CE standard records a time to a permeation rate of 1.0µg / min / cm2, whilst ASTM records a time to a permeation rate of 0.10µg / min / cm2. This may explain differences between results. As with all Personal Protective Equipment, selection should be based upon the end users risk assessment, it is the responsibility of the end user to determine the suitability of any PPE as part of this risk assessment and to comply with any/all legislative/governmental requirements. Contact Lakeland for more information.