ChemMax®

|  |  |  |

|---|---|---|---|

ChemMax 1 | ChemMax 2 | ChemMax 3 | ChemMax 4 Plus |

Low to Moderate Protection | Moderate Protection | Moderate to High Protection | Advanced Protection |

Serged, Bound, & Heat Sealed | Bound & Heat Sealed | Heat Sealed | Heat Sealed |

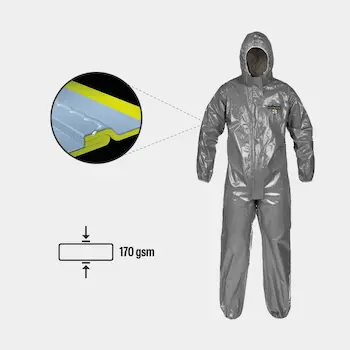

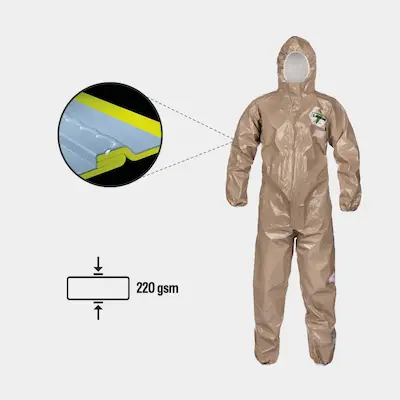

87 gsm | 153 gsm | 170 gsm | 220 gsm |

|  |  |  |

|---|---|---|---|

ChemMax 1 | ChemMax 2 | ChemMax 3 | ChemMax 4 Plus |

Low to Moderate Protection | Moderate Protection | Moderate to High Protection | Advanced Protection |

Taped/Sealed Seam | Taped/Sealed Seam | Stitched/Taped | Stitched/Taped |

87 gsm | 148 gsm, 153 gsm | 170 gsm | 220 gsm |

Why ChemMax?

Whatever your application, Lakeland ChemMax chemical protective clothing is ready for the job. ChemMax products range from lightweight protection to multi-barrier, advanced protection for chemical spray, splash, and other hazards.

With advanced, polymer-based barrier fabrics, Lakeland’s ChemMax garments are designed to optimize garment strength and durability. You can choose from a range of styles, including coveralls, jackets, pants, boot covers, aprons, and more – giving you the flexibility to select configurations that will increase comfort for the wearer.

Lakeland ChemMax® clothing uses fabrics specifically designed and selected to optimize the combination of strength, weight, and flexibility. Chemical suit seam types are available in multiple seam configurations – including bound and heat sealed seams, bringing extensive protection to inner clothing from harmful contamination penetration.

Durable and lightweight, Lakeland ChemMax provides a barrier against a broad spectrum of toxic industrial chemicals, dual-use chemicals, chemical warfare agents, and other harmful contaminants.

ChemMax 1

Low to Moderate Chemical Protection

- Wastewater Treatment

- High and Low pH Chemicals

- Hazardous Liquid Spray

ChemMax 2

Moderate Chemical Protection

- Chemical Mixing and Handling

- Environmental Clean Up

- Hazardous Material Remediation

ChemMax 3

Moderate to High Chemical Protection

- Toxic Industrial Chemicals

- Chemical Warfare Agents

- Fentanyl Protection

ChemMax 4 Plus

Advanced Chemical Protection

- Hazardous Materials Response

- Toxic Industrial Chemicals

- Petrochemical